Filter News

Area of Research

- Advanced Manufacturing (24)

- Biology and Environment (42)

- Building Technologies (3)

- Clean Energy (133)

- Computational Engineering (1)

- Computer Science (2)

- Electricity and Smart Grid (1)

- Energy Sciences (1)

- Functional Materials for Energy (1)

- Fusion and Fission (26)

- Fusion Energy (13)

- Materials (40)

- Materials for Computing (8)

- Mathematics (1)

- National Security (6)

- Neutron Science (9)

- Nuclear Science and Technology (13)

- Quantum information Science (1)

- Supercomputing (13)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (122)

- (-) Fusion (55)

- (-) Mathematics (8)

- (-) Sustainable Energy (126)

- Advanced Reactors (34)

- Artificial Intelligence (91)

- Big Data (55)

- Bioenergy (92)

- Biology (99)

- Biomedical (58)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (65)

- Clean Water (29)

- Climate Change (100)

- Composites (26)

- Computer Science (189)

- Coronavirus (46)

- Critical Materials (26)

- Cybersecurity (35)

- Decarbonization (80)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (109)

- Environment (195)

- Exascale Computing (37)

- Fossil Energy (6)

- Frontier (42)

- Grid (63)

- High-Performance Computing (85)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (48)

- Materials (144)

- Materials Science (141)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (62)

- Net Zero (14)

- Neutron Science (131)

- Nuclear Energy (109)

- Partnerships (44)

- Physics (61)

- Polymers (33)

- Quantum Computing (34)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (48)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

Temperatures hotter than the center of the sun. Magnetic fields hundreds of thousands of times stronger than the earth’s. Neutrons energetic enough to change the structure of a material entirely.

ITER, the world’s largest international scientific collaboration, is beginning assembly of the fusion reactor tokamak that will include 12 different essential hardware systems provided by US ITER, which is managed by Oak Ridge National Laboratory.

Scientists at the Department of Energy Manufacturing Demonstration Facility at ORNL have their eyes on the prize: the Transformational Challenge Reactor, or TCR, a microreactor built using 3D printing and other new approaches that will be up and running by 2023.

Oak Ridge National Laboratory researchers have developed a thin film, highly conductive solid-state electrolyte made of a polymer and ceramic-based composite for lithium metal batteries.

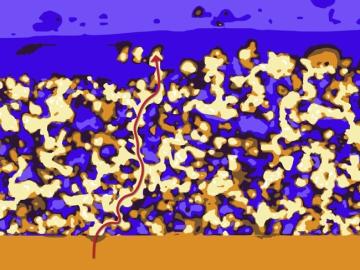

Researchers at the Department of Energy’s Oak Ridge National Laboratory are refining their design of a 3D-printed nuclear reactor core, scaling up the additive manufacturing process necessary to build it, and developing methods

Researchers at Oak Ridge National Laboratory demonstrated a 20-kilowatt bi-directional wireless charging system on a UPS plug-in hybrid electric delivery truck, advancing the technology to a larger class of vehicles and enabling a new energy storage method for fleet owners and their facilities.

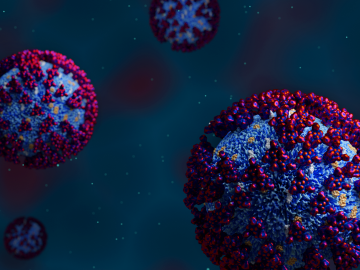

In the fight against the COVID-19 pandemic, it’s a race against the clock not only to find a vaccine but also to supply healthcare workers with life-saving equipment such as face shields, masks and test kits.

Suman Debnath, a researcher at ORNL, has been elevated to the grade of senior member of the Institute of Electrical and Electronics Engineers (IEEE).

Brian Post, a researcher in large-scale additive manufacturing at ORNL, has been selected as a recipient of the 2020 Outstanding Young Manufacturing Engineer Award by SME.

In the race to identify solutions to the COVID-19 pandemic, researchers at the Department of Energy’s Oak Ridge National Laboratory are joining the fight by applying expertise in computational science, advanced manufacturing, data science and neutron science.