Filter News

Area of Research

- Advanced Manufacturing (2)

- Biology and Environment (26)

- Biology and Soft Matter (1)

- Clean Energy (47)

- Computational Biology (1)

- Computational Engineering (1)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (1)

- Fusion and Fission (3)

- Materials (43)

- Materials for Computing (6)

- Mathematics (1)

- National Security (6)

- Neutron Science (100)

- Nuclear Science and Technology (9)

- Supercomputing (19)

- Transportation Systems (1)

News Topics

- (-) Decarbonization (79)

- (-) Mathematics (7)

- (-) Molten Salt (8)

- (-) Neutron Science (131)

- 3-D Printing/Advanced Manufacturing (121)

- Advanced Reactors (34)

- Artificial Intelligence (91)

- Big Data (53)

- Bioenergy (91)

- Biology (98)

- Biomedical (58)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (63)

- Clean Water (29)

- Climate Change (99)

- Composites (26)

- Computer Science (187)

- Coronavirus (46)

- Critical Materials (26)

- Cybersecurity (35)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (108)

- Environment (194)

- Exascale Computing (37)

- Fossil Energy (5)

- Frontier (42)

- Fusion (54)

- Grid (62)

- High-Performance Computing (84)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (47)

- Materials (144)

- Materials Science (140)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Nanotechnology (60)

- National Security (61)

- Net Zero (13)

- Nuclear Energy (108)

- Partnerships (44)

- Physics (61)

- Polymers (33)

- Quantum Computing (34)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (47)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Sustainable Energy (125)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

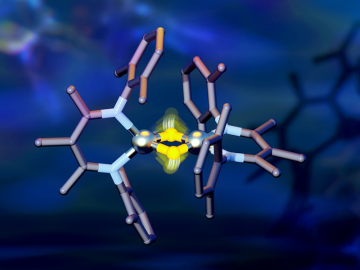

Researchers from Yale University and ORNL collaborated on neutron scattering experiments to study hydrogen atom locations and their effects on iron in a compound similar to those commonly used in industrial catalysts.

Hydrologist Jesús “Chucho” Gomez-Velez is in the right place at the right time with the right tools and colleagues to explain how the smallest processes within river corridors can have a tremendous impact on large-scale ecosystems.

The Department of Energy’s Center for Bioenergy Innovation, led by Oak Ridge National Laboratory, recently added three new members to its board of directors: Deborah Crawford of the University of Tennessee, Knoxville; Susan Hubbard of ORNL; and Maureen McCann of the National Renewable Energy Laboratory.

The truth is neutron scattering is not important, according to Steve Nagler. The knowledge gained from using it is what’s important

Paul Langan will join ORNL in the spring as associate laboratory director for the Biological and Environmental Systems Science Directorate.

David McCollum, a senior scientist at the ORNL and lead for the lab’s contributions to the Net Zero World Initiative, was one of more than 35,000 attendees in Egypt at the November 2022 Sharm El-Sheikh United Nations Framework Convention on Climate Change, or UNFCCC, Conference of the Parties, also known as COP27.

The U.S. Departments of Energy and Defense teamed up to create a series of weld filler materials that could dramatically improve high-strength steel repair in vehicles, bridges and pipelines.

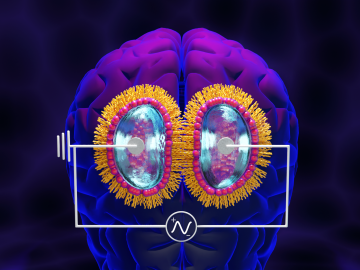

While studying how bio-inspired materials might inform the design of next-generation computers, scientists at ORNL achieved a first-of-its-kind result that could have big implications for both edge computing and human health.

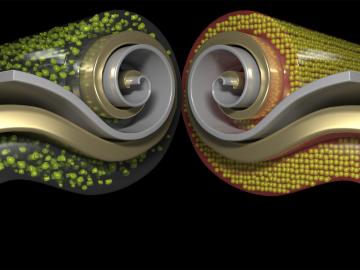

Researchers at ORNL have developed a new method for producing a key component of lithium-ion batteries. The result is a more affordable battery from a faster, less wasteful process that uses less toxic material.

Oak Ridge National Laboratory scientists designed a recyclable polymer for carbon-fiber composites to enable circular manufacturing of parts that boost energy efficiency in automotive, wind power and aerospace applications.