Filter News

Area of Research

- Advanced Manufacturing (24)

- Biological Systems (1)

- Biology and Environment (128)

- Biology and Soft Matter (1)

- Building Technologies (3)

- Clean Energy (181)

- Climate and Environmental Systems (5)

- Computational Biology (2)

- Computational Engineering (2)

- Computer Science (3)

- Electricity and Smart Grid (1)

- Energy Frontier Research Centers (1)

- Energy Sciences (1)

- Functional Materials for Energy (1)

- Fusion and Fission (12)

- Fusion Energy (9)

- Isotopes (6)

- Materials (111)

- Materials for Computing (18)

- Mathematics (1)

- National Security (18)

- Neutron Science (104)

- Nuclear Science and Technology (20)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Quantum information Science (2)

- Supercomputing (62)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (121)

- (-) Advanced Reactors (34)

- (-) Biomedical (58)

- (-) Environment (194)

- (-) Nanotechnology (60)

- (-) Neutron Science (131)

- (-) Sustainable Energy (125)

- Artificial Intelligence (91)

- Big Data (53)

- Bioenergy (91)

- Biology (98)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (63)

- Clean Water (29)

- Climate Change (99)

- Composites (26)

- Computer Science (187)

- Coronavirus (46)

- Critical Materials (26)

- Cybersecurity (35)

- Decarbonization (79)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (108)

- Exascale Computing (37)

- Fossil Energy (5)

- Frontier (42)

- Fusion (54)

- Grid (62)

- High-Performance Computing (84)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (47)

- Materials (144)

- Materials Science (140)

- Mathematics (7)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Molten Salt (8)

- National Security (61)

- Net Zero (13)

- Nuclear Energy (108)

- Partnerships (44)

- Physics (61)

- Polymers (33)

- Quantum Computing (34)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (47)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

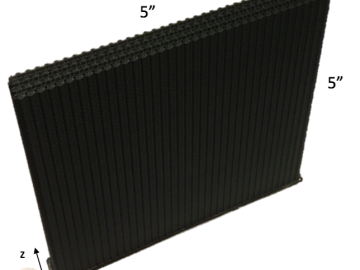

A team including Oak Ridge National Laboratory and University of Tennessee researchers demonstrated a novel 3D printing approach called Z-pinning that can increase the material’s strength and toughness by more than three and a half times compared to conventional additive manufacturing processes.

Ask Tyler Gerczak to find a negative in working at the Department of Energy’s Oak Ridge National Laboratory, and his only complaint is the summer weather. It is not as forgiving as the summers in Pulaski, Wisconsin, his hometown.

Craig Blue, a program director at the Department of Energy’s Oak Ridge National Laboratory, has been elected a 2019 fellow for SME (formerly known as the Society for Manufacturing Engineers).

Electro-Active Technologies, Inc., of Knoxville, Tenn., has exclusively licensed two biorefinery technologies invented and patented by the startup’s co-founders while working at the Department of Energy’s Oak Ridge National Laboratory. The technologies work as a system that converts organic waste into renewable hydrogen gas for use as a biofuel.

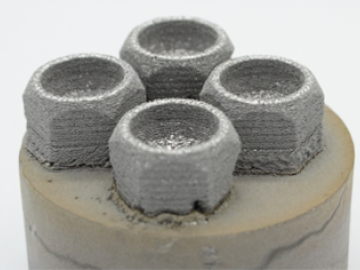

Using additive manufacturing, scientists experimenting with tungsten at Oak Ridge National Laboratory hope to unlock new potential of the high-performance heat-transferring material used to protect components from the plasma inside a fusion reactor. Fusion requires hydrogen isotopes to reach millions of degrees.

A detailed study by Oak Ridge National Laboratory estimated how much more—or less—energy United States residents might consume by 2050 relative to predicted shifts in seasonal weather patterns

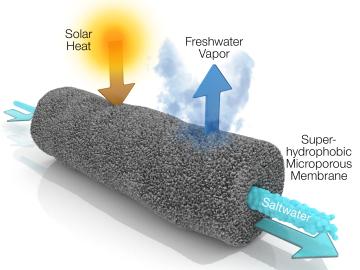

A new method developed at Oak Ridge National Laboratory improves the energy efficiency of a desalination process known as solar-thermal evaporation.

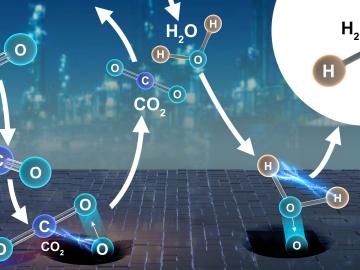

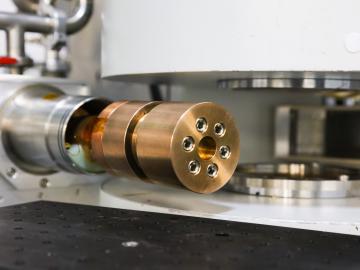

Collaborators at the Department of Energy’s Oak Ridge National Laboratory and U.S. universities used neutron scattering and other advanced characterization techniques to study how a prominent catalyst enables the “water-gas shift” reaction to purify and generate hydrogen at industrial scale.

A team of scientists led by Oak Ridge National Laboratory have discovered the specific gene that controls an important symbiotic relationship between plants and soil fungi, and successfully facilitated the symbiosis in a plant that

Researchers have pioneered a new technique using pressure to manipulate magnetism in thin film materials used to enhance performance in electronic devices.