Filter News

Area of Research

- Advanced Manufacturing (22)

- Biology and Environment (19)

- Building Technologies (1)

- Clean Energy (93)

- Fusion and Fission (9)

- Fusion Energy (7)

- Materials (60)

- Materials for Computing (8)

- National Security (3)

- Neutron Science (10)

- Nuclear Science and Technology (13)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Quantum information Science (2)

- Supercomputing (16)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (122)

- (-) Advanced Reactors (34)

- (-) Critical Materials (26)

- (-) Microscopy (51)

- Artificial Intelligence (91)

- Big Data (55)

- Bioenergy (92)

- Biology (99)

- Biomedical (58)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (65)

- Clean Water (29)

- Climate Change (100)

- Composites (26)

- Computer Science (189)

- Coronavirus (46)

- Cybersecurity (35)

- Decarbonization (80)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (109)

- Environment (195)

- Exascale Computing (37)

- Fossil Energy (6)

- Frontier (42)

- Fusion (55)

- Grid (63)

- High-Performance Computing (85)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (48)

- Materials (144)

- Materials Science (141)

- Mathematics (8)

- Mercury (12)

- Microelectronics (3)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (62)

- Net Zero (14)

- Neutron Science (131)

- Nuclear Energy (109)

- Partnerships (44)

- Physics (61)

- Polymers (33)

- Quantum Computing (34)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (48)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Sustainable Energy (126)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

Researchers at ORNL have developed an online tool that offers industrial plants an easier way to track and download information about their energy footprint and carbon emissions.

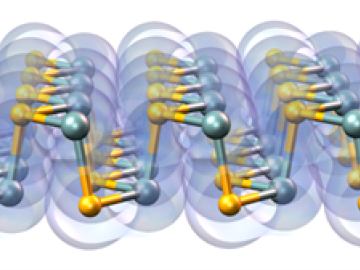

A multi-lab research team led by ORNL's Paul Kent is developing a computer application called QMCPACK to enable precise and reliable predictions of the fundamental properties of materials critical in energy research.

Five technologies invented by scientists at the Department of Energy’s Oak Ridge National Laboratory have been selected for targeted investment through ORNL’s Technology Innovation Program.

Scientists at ORNL have created a miniaturized environment to study the ecosystem around poplar tree roots for insights into plant health and soil carbon sequestration.

Larry Allard, a distinguished research staff member at Oak Ridge National Laboratory, has been named a Fellow of the Microanalysis Society.

Researchers at Oak Ridge National Laboratory and Momentum Technologies have piloted an industrial-scale process for recycling valuable materials in the millions of tons of e-waste generated annually in the United States.

Chemical and environmental engineer Samarthya Bhagia is focused on achieving carbon neutrality and a circular economy by designing new plant-based materials for a range of applications from energy storage devices and sensors to environmentally friendly bioplastics.

ORNL researchers have developed an upcycling approach that adds value to discarded plastics for reuse in additive manufacturing, or 3D printing.

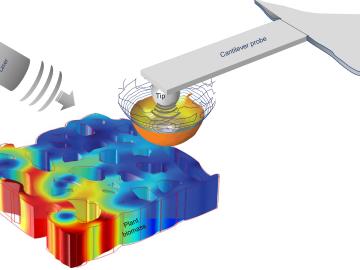

To optimize biomaterials for reliable, cost-effective paper production, building construction, and biofuel development, researchers often study the structure of plant cells using techniques such as freezing plant samples or placing them in a vacuum.

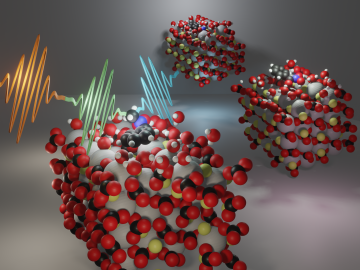

Researchers at Oak Ridge National Laboratory are using state-of-the-art methods to shed light on chemical separations needed to recover rare-earth elements and secure critical materials for clean energy technologies.