Filter News

Area of Research

- Advanced Manufacturing (7)

- Biology and Environment (12)

- Clean Energy (42)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (2)

- Fusion and Fission (8)

- Fusion Energy (8)

- Isotope Development and Production (1)

- Isotopes (7)

- Materials (78)

- Materials Characterization (2)

- Materials for Computing (11)

- Materials Under Extremes (1)

- National Security (3)

- Neutron Science (18)

- Nuclear Science and Technology (19)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Supercomputing (19)

News Topics

- (-) Advanced Reactors (34)

- (-) Materials (144)

- (-) Molten Salt (8)

- (-) Space Exploration (25)

- 3-D Printing/Advanced Manufacturing (121)

- Artificial Intelligence (91)

- Big Data (53)

- Bioenergy (91)

- Biology (98)

- Biomedical (58)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (63)

- Clean Water (29)

- Climate Change (99)

- Composites (26)

- Computer Science (187)

- Coronavirus (46)

- Critical Materials (26)

- Cybersecurity (35)

- Decarbonization (79)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (108)

- Environment (194)

- Exascale Computing (37)

- Fossil Energy (5)

- Frontier (42)

- Fusion (54)

- Grid (62)

- High-Performance Computing (84)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (47)

- Materials Science (140)

- Mathematics (7)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Nanotechnology (60)

- National Security (61)

- Net Zero (13)

- Neutron Science (131)

- Nuclear Energy (108)

- Partnerships (44)

- Physics (61)

- Polymers (33)

- Quantum Computing (34)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (47)

- Software (1)

- Statistics (3)

- Summit (57)

- Sustainable Energy (125)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

A better way of welding targets for Oak Ridge National Laboratory’s plutonium-238 production has sped up the process and improved consistency and efficiency. This advancement will ultimately benefit the lab’s goal to make enough Pu-238 – the isotope that powers NASA’s deep space missions – to yield 1.5 kilograms of plutonium oxide annually by 2026.

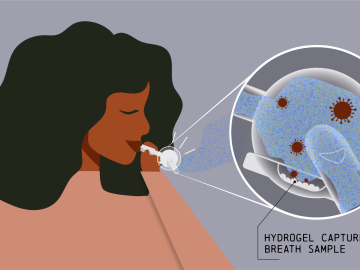

Collaborators at Oak Ridge National Laboratory and the University of Tennessee Health Science Center are developing a breath-sampling whistle that could make COVID-19 screening easy to do at home.

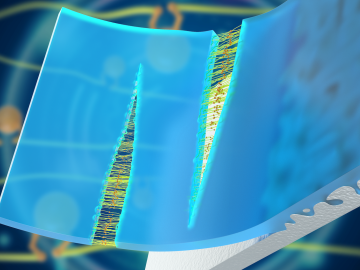

The ExOne Company, the global leader in industrial sand and metal 3D printers using binder jetting technology, announced it has reached a commercial license agreement with Oak Ridge National Laboratory to 3D print parts in aluminum-infiltrated boron carbide.

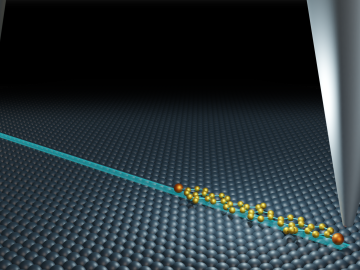

Oak Ridge National Laboratory’s Center for Nanophase Materials Sciences contributed to a groundbreaking experiment published in Science that tracks the real-time transport of individual molecules.

Six scientists at the Department of Energy’s Oak Ridge National Laboratory were named Battelle Distinguished Inventors, in recognition of obtaining 14 or more patents during their careers at the lab.

The annual Director's Awards recognized four individuals and teams including awards for leadership in quantum simulation development and application on high-performance computing platforms, and revolutionary advancements in the area of microbial

David Kropaczek, director of the Consortium for Advanced Simulation of Light Water Reactors, or CASL, at the Department of Energy’s Oak Ridge National Laboratory, has been named a fellow of the American Nuclear Society.

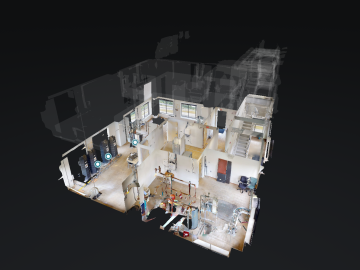

ORNL has added 10 virtual tours to its campus map, each with multiple views to show floor plans, rotating dollhouse views and 360-degree navigation. As a user travels through a map, pop-out informational windows deliver facts, videos, graphics and links to other related content.

The Transformational Challenge Reactor, or TCR, a microreactor built using 3D printing and other new advanced technologies, could be operational by 2024.