Filter News

Area of Research

- Advanced Manufacturing (1)

- Biology and Environment (16)

- Clean Energy (29)

- Computational Biology (1)

- Fusion and Fission (6)

- Fusion Energy (7)

- Materials (25)

- Materials for Computing (8)

- National Security (3)

- Neutron Science (10)

- Nuclear Science and Technology (12)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Supercomputing (17)

News Topics

- (-) Advanced Reactors (34)

- (-) Coronavirus (46)

- (-) Polymers (33)

- 3-D Printing/Advanced Manufacturing (125)

- Artificial Intelligence (94)

- Big Data (58)

- Bioenergy (92)

- Biology (100)

- Biomedical (59)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (66)

- Clean Water (30)

- Climate Change (101)

- Composites (28)

- Computer Science (193)

- Critical Materials (28)

- Cybersecurity (35)

- Decarbonization (80)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (109)

- Environment (196)

- Exascale Computing (39)

- Fossil Energy (6)

- Frontier (44)

- Fusion (55)

- Grid (65)

- High-Performance Computing (88)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (48)

- Materials (144)

- Materials Science (142)

- Mathematics (9)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (65)

- Net Zero (14)

- Neutron Science (131)

- Nuclear Energy (109)

- Partnerships (46)

- Physics (62)

- Quantum Computing (35)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (49)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (59)

- Sustainable Energy (129)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

Oak Ridge National Laboratory researchers collaborated with Iowa State University and RJ Lee Group to demonstrate a safe and effective antiviral coating for N95 masks. The coating destroys the COVID-19-causing coronavirus and could enable reuse of masks made from various fabrics.

ORNL and the Tennessee Valley Authority, or TVA, are joining forces to advance decarbonization technologies from discovery through deployment through a new memorandum of understanding, or MOU.

ORNL, TVA and TNECD were recognized by the Federal Laboratory Consortium for their impactful partnership that resulted in a record $2.3 billion investment by Ultium Cells, a General Motors and LG Energy Solution joint venture, to build a battery cell manufacturing plant in Spring Hill, Tennessee.

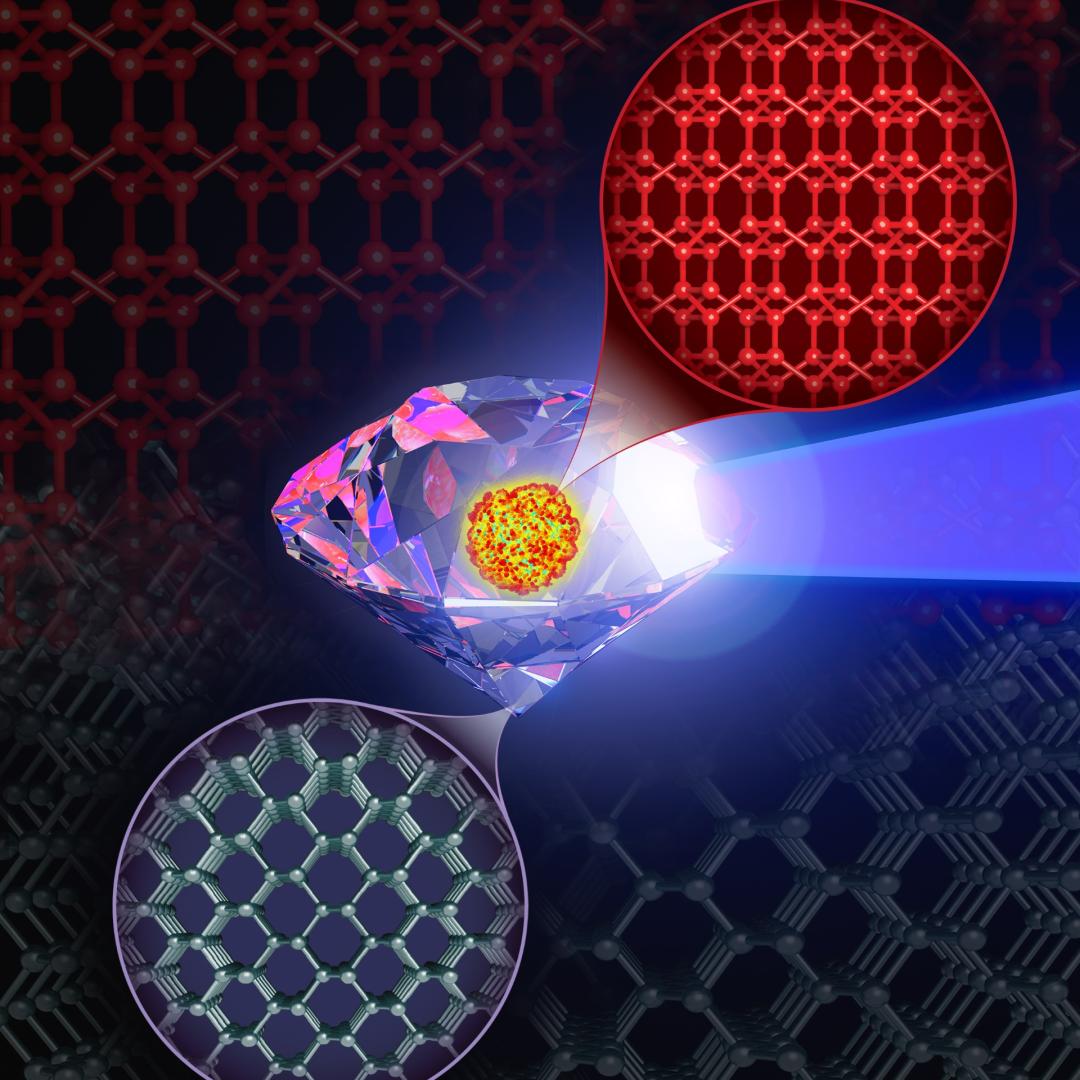

To explore the inner workings of severe acute respiratory syndrome coronavirus 2, or SARS-CoV-2, researchers from ORNL developed a novel technique.

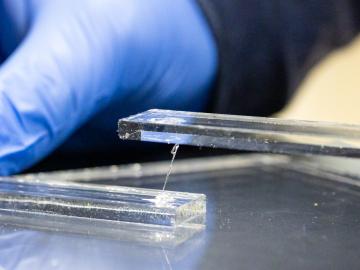

Researchers at ORNL used polymer chemistry to transform a common household plastic into a reusable adhesive with a rare combination of strength and ductility, making it one of the toughest materials ever reported.

A novel method to 3D print components for nuclear reactors, developed by the Department of Energy’s Oak Ridge National Laboratory, has been licensed by Ultra Safe Nuclear Corporation.

Oak Ridge National Laboratory researchers have retrofitted a commercial refrigeration container designed to ensure COVID-19 vaccines remain at ultra-low temperatures during long transport and while locally stored.

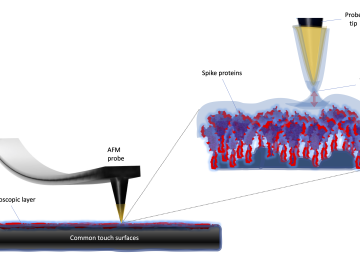

A study by Department of Energy researchers detailed a potential method to detect the novel coronavirus

Ten scientists from the Department of Energy’s Oak Ridge National Laboratory are among the world’s most highly cited researchers, according to a bibliometric analysis conducted by the scientific publication analytics firm Clarivate.

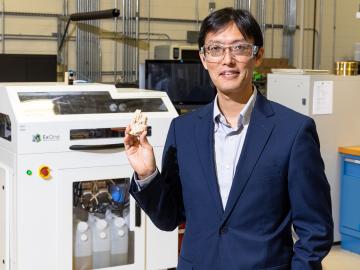

Researchers at ORNL designed a novel polymer to bind and strengthen silica sand for binder jet additive manufacturing, a 3D-printing method used by industries for prototyping and part production.