Filter News

Area of Research

- Advanced Manufacturing (3)

- Biology and Environment (61)

- Biology and Soft Matter (1)

- Clean Energy (108)

- Climate and Environmental Systems (3)

- Computational Biology (1)

- Computational Engineering (2)

- Computer Science (6)

- Electricity and Smart Grid (1)

- Fuel Cycle Science and Technology (2)

- Functional Materials for Energy (1)

- Fusion and Fission (31)

- Fusion Energy (13)

- Isotope Development and Production (1)

- Isotopes (26)

- Materials (57)

- Materials for Computing (9)

- Mathematics (1)

- National Security (53)

- Neutron Science (20)

- Nuclear Science and Technology (42)

- Nuclear Systems Modeling, Simulation and Validation (2)

- Sensors and Controls (1)

- Supercomputing (88)

- Transportation Systems (2)

News Topics

- (-) Advanced Reactors (34)

- (-) Artificial Intelligence (91)

- (-) Climate Change (100)

- (-) Frontier (42)

- (-) Isotopes (53)

- (-) Mercury (12)

- (-) Molten Salt (8)

- (-) National Security (63)

- (-) Nuclear Energy (109)

- (-) Security (24)

- (-) Transportation (97)

- 3-D Printing/Advanced Manufacturing (122)

- Big Data (55)

- Bioenergy (92)

- Biology (99)

- Biomedical (58)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (65)

- Clean Water (29)

- Composites (26)

- Computer Science (189)

- Coronavirus (46)

- Critical Materials (26)

- Cybersecurity (35)

- Decarbonization (80)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (109)

- Environment (195)

- Exascale Computing (37)

- Fossil Energy (6)

- Fusion (55)

- Grid (63)

- High-Performance Computing (85)

- Hydropower (11)

- Irradiation (3)

- ITER (7)

- Machine Learning (48)

- Materials (144)

- Materials Science (141)

- Mathematics (9)

- Microelectronics (3)

- Microscopy (51)

- Nanotechnology (60)

- Net Zero (14)

- Neutron Science (131)

- Partnerships (44)

- Physics (61)

- Polymers (33)

- Quantum Computing (34)

- Quantum Science (69)

- Renewable Energy (2)

- Simulation (48)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Sustainable Energy (126)

- Transformational Challenge Reactor (7)

Media Contacts

Kevin Field at the Department of Energy’s Oak Ridge National Laboratory synthesizes and scrutinizes materials for nuclear power systems that must perform safely and efficiently over decades of irradiation.

Oak Ridge National Laboratory is using ultrasonic additive manufacturing to embed highly accurate fiber optic sensors in heat- and radiation-resistant materials, allowing for real-time monitoring that could lead to greater insights and safer reactors.

Oak Ridge National Laboratory’s latest Transportation Energy Data Book: Edition 37 reports that the number of vehicles nationwide is growing faster than the population, with sales more than 17 million since 2015, and the average household vehicle travels more than 11,000 miles per year.

OAK RIDGE, Tenn., March 4, 2019—A team of researchers from the Department of Energy’s Oak Ridge National Laboratory Health Data Sciences Institute have harnessed the power of artificial intelligence to better match cancer patients with clinical trials.

Scientists have tested a novel heat-shielding graphite foam, originally created at Oak Ridge National Laboratory, at Germany’s Wendelstein 7-X stellarator with promising results for use in plasma-facing components of fusion reactors.

Oak Ridge National Laboratory scientists have created open source software that scales up analysis of motor designs to run on the fastest computers available, including those accessible to outside users at the Oak Ridge Leadership Computing Facility.

OAK RIDGE, Tenn., Feb. 12, 2019—A team of researchers from the Department of Energy’s Oak Ridge and Los Alamos National Laboratories has partnered with EPB, a Chattanooga utility and telecommunications company, to demonstrate the effectiveness of metro-scale quantum key distribution (QKD).

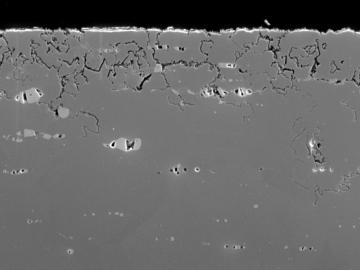

Oak Ridge National Laboratory scientists analyzed more than 50 years of data showing puzzlingly inconsistent trends about corrosion of structural alloys in molten salts and found one factor mattered most—salt purity.

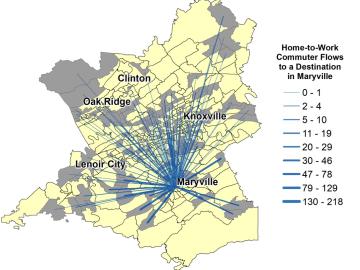

Oak Ridge National Laboratory geospatial scientists who study the movement of people are using advanced machine learning methods to better predict home-to-work commuting patterns.

OAK RIDGE, Tenn., Jan. 31, 2019—A new electron microscopy technique that detects the subtle changes in the weight of proteins at the nanoscale—while keeping the sample intact—could open a new pathway for deeper, more comprehensive studies of the basic building blocks of life.