Filter News

Area of Research

- Advanced Manufacturing (22)

- Biology and Environment (26)

- Building Technologies (1)

- Clean Energy (153)

- Computational Engineering (1)

- Fusion and Fission (7)

- Fusion Energy (1)

- Materials (45)

- Materials for Computing (9)

- Mathematics (1)

- National Security (8)

- Neutron Science (13)

- Nuclear Science and Technology (4)

- Supercomputing (12)

- Transportation Systems (2)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (122)

- (-) Clean Water (29)

- (-) Partnerships (44)

- (-) Transportation (97)

- Advanced Reactors (34)

- Artificial Intelligence (91)

- Big Data (55)

- Bioenergy (92)

- Biology (99)

- Biomedical (58)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (65)

- Climate Change (100)

- Composites (26)

- Computer Science (189)

- Coronavirus (46)

- Critical Materials (26)

- Cybersecurity (35)

- Decarbonization (80)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (109)

- Environment (195)

- Exascale Computing (37)

- Fossil Energy (6)

- Frontier (42)

- Fusion (55)

- Grid (63)

- High-Performance Computing (85)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (48)

- Materials (144)

- Materials Science (141)

- Mathematics (8)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (62)

- Net Zero (14)

- Neutron Science (131)

- Nuclear Energy (109)

- Physics (61)

- Polymers (33)

- Quantum Computing (34)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (48)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Sustainable Energy (126)

- Transformational Challenge Reactor (7)

Media Contacts

A team of researchers at ORNL demonstrated that a light-duty passenger electric vehicle can be wirelessly charged at 100-kW with 96% efficiency using polyphase electromagnetic coupling coils with rotating magnetic fields.

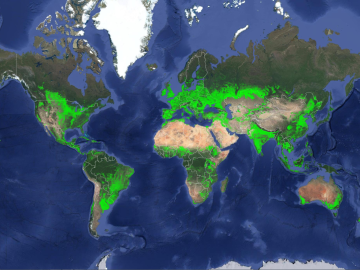

ORNL climate modeling expertise contributed to a project that assessed global emissions of ammonia from croplands now and in a warmer future, while also identifying solutions tuned to local growing conditions.

Four ORNL teams and one researcher were recognized for excellence in technology transfer and technology transfer innovation.

Technology Transfer staff from Department of Energy’s Oak Ridge National Laboratory attended the 2024 Consumer Electronics Show, or CES, in Las Vegas, Jan. 8–12.

Louise Stevenson uses her expertise as an environmental toxicologist to evaluate the effects of stressors such as chemicals and other contaminants on aquatic systems.

Electric vehicles can drive longer distances if their lithium-ion batteries deliver more energy in a lighter package. A prime weight-loss candidate is the current collector, a component that often adds 10% to the weight of a battery cell without contributing energy.

Scientists at ORNL have developed a technique for recovering and recycling critical materials that has garnered special recognition from a peer-reviewed materials journal and received a new phase of funding for research and development.

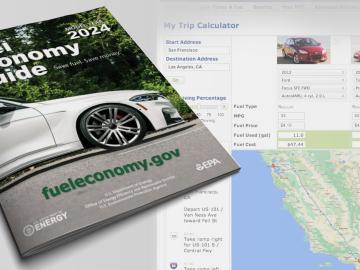

Oak Ridge National Laboratory researchers have identified the most energy-efficient 2024 model year vehicles available in the United States, including electric and hybrids, in the latest edition of the Department of Energy’s Fuel Economy Guide.

Ateios Systems licensed an ORNL technology for solvent-free battery component production using electron curing. Through Innovation Crossroads, Ateios continues to work with ORNL to enable readiness for production-quality battery components.

Researchers at ORNL became the first to 3D-print large rotating steam turbine blades for generating energy in power plants.