Filter News

Area of Research

- Advanced Manufacturing (22)

- Biology and Environment (25)

- Building Technologies (1)

- Clean Energy (89)

- Computational Engineering (1)

- Electricity and Smart Grid (2)

- Functional Materials for Energy (1)

- Fusion and Fission (4)

- Fusion Energy (2)

- Materials (29)

- Materials for Computing (4)

- Mathematics (1)

- National Security (3)

- Neutron Science (9)

- Nuclear Science and Technology (4)

- Supercomputing (33)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (124)

- (-) Clean Water (30)

- (-) Frontier (44)

- (-) Microelectronics (3)

- Advanced Reactors (34)

- Artificial Intelligence (94)

- Big Data (58)

- Bioenergy (92)

- Biology (100)

- Biomedical (59)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (66)

- Climate Change (101)

- Composites (28)

- Computer Science (193)

- Coronavirus (46)

- Critical Materials (28)

- Cybersecurity (35)

- Decarbonization (80)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (109)

- Environment (196)

- Exascale Computing (39)

- Fossil Energy (6)

- Fusion (55)

- Grid (65)

- High-Performance Computing (88)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (48)

- Materials (144)

- Materials Science (142)

- Mathematics (9)

- Mercury (12)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (65)

- Net Zero (14)

- Neutron Science (131)

- Nuclear Energy (109)

- Partnerships (46)

- Physics (62)

- Polymers (33)

- Quantum Computing (35)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (49)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (59)

- Sustainable Energy (129)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

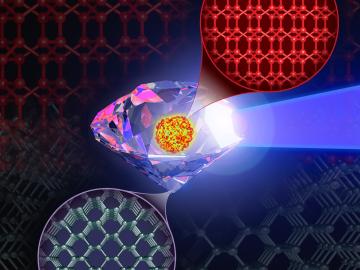

The world’s fastest supercomputer helped researchers simulate synthesizing a material harder and tougher than diamond — or any other substance on Earth. The study used Frontier to predict the likeliest strategy to synthesize such a material, thought to exist so far only within the interiors of giant exoplanets, or planets beyond our solar system.

The contract will be awarded to develop the newest high-performance computing system at the Oak Ridge Leadership Computing Facility.

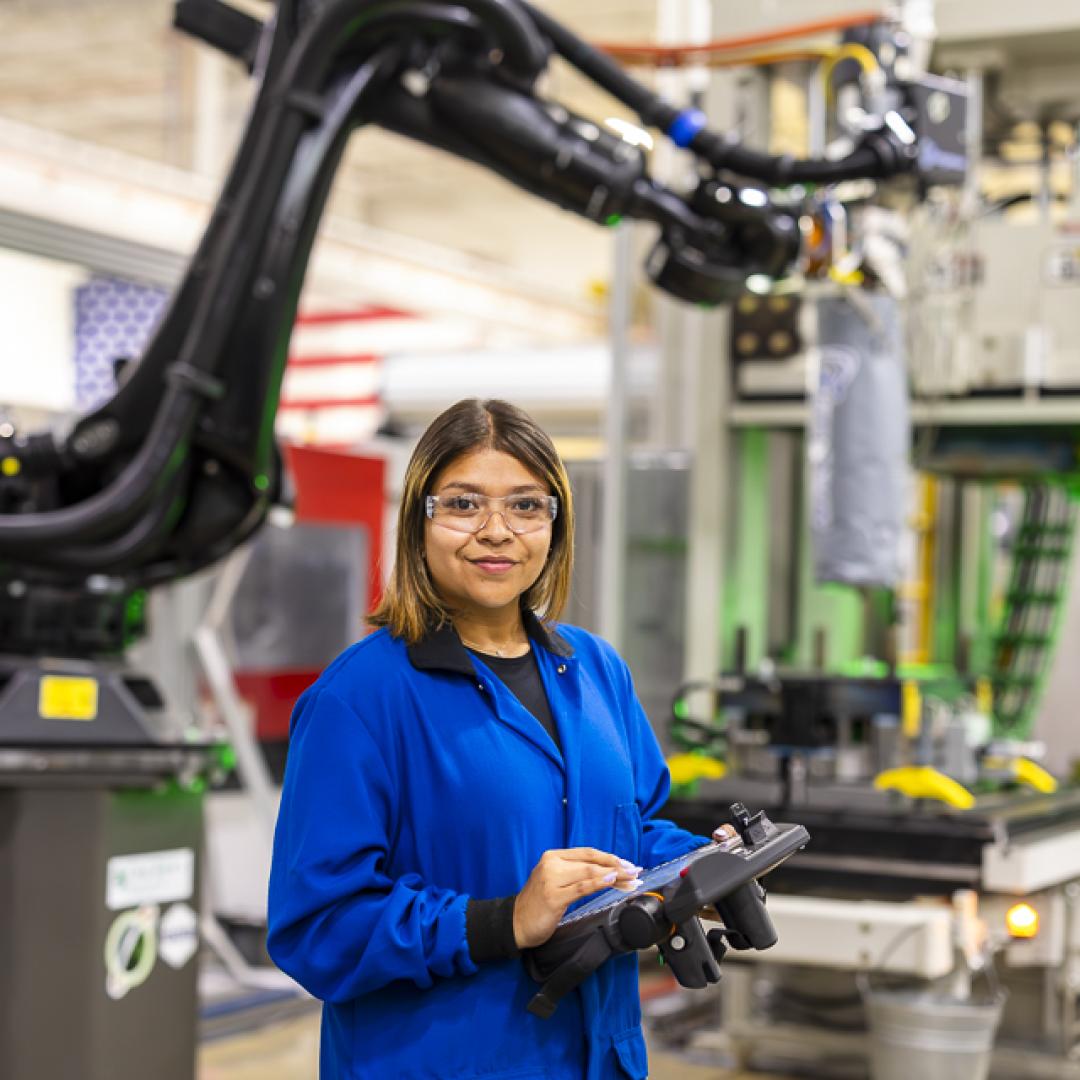

Brittany Rodriguez never imagined she would pursue a science career at a Department of Energy national laboratory. However, after some encouraging words from her mother, input from key mentors at the University of Texas Rio Grande Valley, or UTRGV, and a lot of hard work, Rodriguez landed at DOE’s Manufacturing Demonstration Facility, or MDF, at Oak Ridge National Laboratory.

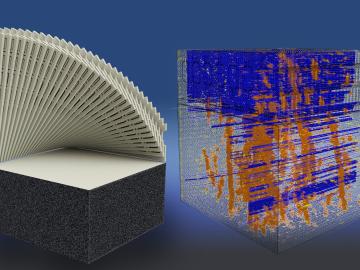

The Department of Energy’s Oak Ridge National Laboratory has publicly released a new set of additive manufacturing data that industry and researchers can use to evaluate and improve the quality of 3D-printed components. The breadth of the datasets can significantly boost efforts to verify the quality of additively manufactured parts using only information gathered during printing, without requiring expensive and time-consuming post-production analysis.

To better predict long-term flooding risk, scientists at the Department of Energy’s Oak Ridge National Laboratory developed a 3D modeling framework that captures the complex dynamics of water as it flows across the landscape. The framework seeks to provide valuable insights into which communities are most vulnerable as the climate changes, and was developed for a project that’s assessing climate risk and mitigation pathways for an urban area along the Southeast Texas coast.

Participants in the SM2ART Research Experience for Undergraduates program got the chance to see what life is like in a research setting. REU participant Brianna Greer studied banana fibers as a reinforcing material in making lightweight parts for cars and bicycles.

Advanced materials research to enable energy-efficient, cost-competitive and environmentally friendly technologies for the United States and Japan is the goal of a memorandum of understanding, or MOU, between the Department of Energy’s Oak Ridge National Laboratory and Japan’s National Institute of Materials Science.

Researchers at ORNL have developed the first additive manufacturing slicing computer application to simultaneously speed and simplify digital conversion of accurate, large-format three-dimensional parts in a factory production setting.

ORNL researchers completed successful testing of a gallium nitride transistor for use in more accurate sensors operating near the core of a nuclear reactor. This is an important technical advance particularly for monitoring new, compact.

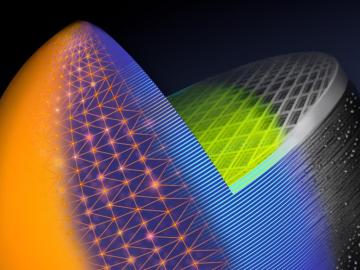

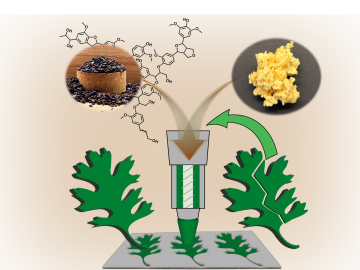

Oak Ridge National Laboratory scientists ingeniously created a sustainable, soft material by combining rubber with woody reinforcements and incorporating “smart” linkages between the components that unlock on demand.