Filter News

Area of Research

- Advanced Manufacturing (22)

- Biology and Environment (31)

- Building Technologies (1)

- Clean Energy (94)

- Computational Biology (1)

- Computational Engineering (1)

- Fuel Cycle Science and Technology (1)

- Fusion and Fission (27)

- Fusion Energy (10)

- Isotope Development and Production (1)

- Isotopes (3)

- Materials (38)

- Materials for Computing (6)

- Mathematics (1)

- National Security (9)

- Neutron Science (17)

- Nuclear Science and Technology (37)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Supercomputing (20)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (122)

- (-) Clean Water (29)

- (-) Coronavirus (46)

- (-) Nuclear Energy (109)

- Advanced Reactors (34)

- Artificial Intelligence (91)

- Big Data (55)

- Bioenergy (92)

- Biology (99)

- Biomedical (58)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (65)

- Climate Change (100)

- Composites (26)

- Computer Science (189)

- Critical Materials (26)

- Cybersecurity (35)

- Decarbonization (80)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (109)

- Environment (195)

- Exascale Computing (37)

- Fossil Energy (6)

- Frontier (42)

- Fusion (55)

- Grid (63)

- High-Performance Computing (85)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (48)

- Materials (144)

- Materials Science (141)

- Mathematics (9)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (63)

- Net Zero (14)

- Neutron Science (131)

- Partnerships (44)

- Physics (61)

- Polymers (33)

- Quantum Computing (34)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (48)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Sustainable Energy (126)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

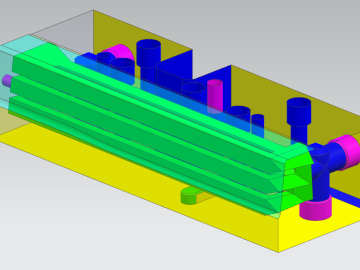

Researchers demonstrated that an additively manufactured hot stamping die can withstand up to 25,000 usage cycles, proving that this technique is a viable solution for production.

Researchers at the Department of Energy’s Oak Ridge National Laboratory have received five 2019 R&D 100 Awards, increasing the lab’s total to 221 since the award’s inception in 1963.

Jason Nattress, an Alvin M. Weinberg Fellow at the Department of Energy’s Oak Ridge National Laboratory, found his calling on a nuclear submarine.

The U.S. Department of Energy announced funding for 12 projects with private industry to enable collaboration with DOE national laboratories on overcoming challenges in fusion energy development.

ORNL and The University of Toledo have entered into a memorandum of understanding for collaborative research.

The National Alliance for Water Innovation, a partnership of the Department of Energy’s Oak Ridge National Laboratory, other national labs, university and private sector partners, has been awarded a five-year, $100 million Energy-Water Desalination Hub by DOE to address water security issues in the United States.

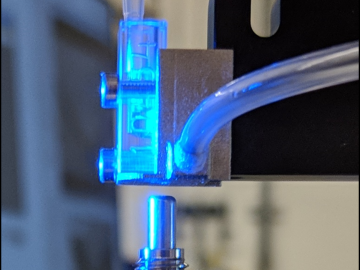

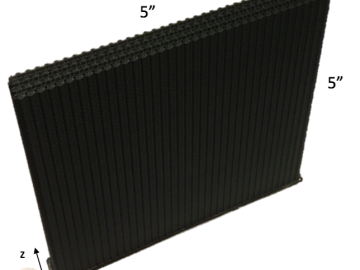

A team including Oak Ridge National Laboratory and University of Tennessee researchers demonstrated a novel 3D printing approach called Z-pinning that can increase the material’s strength and toughness by more than three and a half times compared to conventional additive manufacturing processes.

Ask Tyler Gerczak to find a negative in working at the Department of Energy’s Oak Ridge National Laboratory, and his only complaint is the summer weather. It is not as forgiving as the summers in Pulaski, Wisconsin, his hometown.

Six new nuclear reactor technologies are set to deploy for commercial use between 2030 and 2040. Called Generation IV nuclear reactors, they will operate with improved performance at dramatically higher temperatures than today’s reactors.

Craig Blue, a program director at the Department of Energy’s Oak Ridge National Laboratory, has been elected a 2019 fellow for SME (formerly known as the Society for Manufacturing Engineers).