Filter News

Area of Research

- Advanced Manufacturing (22)

- Biology and Environment (12)

- Building Technologies (4)

- Clean Energy (113)

- Computer Science (4)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (1)

- Fusion and Fission (4)

- Fusion Energy (1)

- Materials (39)

- Materials for Computing (7)

- National Security (4)

- Neutron Science (13)

- Nuclear Science and Technology (4)

- Quantum information Science (9)

- Supercomputing (33)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (124)

- (-) Buildings (57)

- (-) Composites (28)

- (-) Quantum Science (69)

- Advanced Reactors (34)

- Artificial Intelligence (94)

- Big Data (57)

- Bioenergy (92)

- Biology (100)

- Biomedical (59)

- Biotechnology (22)

- Chemical Sciences (66)

- Clean Water (30)

- Climate Change (101)

- Computer Science (192)

- Coronavirus (46)

- Critical Materials (27)

- Cybersecurity (35)

- Decarbonization (80)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (109)

- Environment (196)

- Exascale Computing (38)

- Fossil Energy (6)

- Frontier (43)

- Fusion (55)

- Grid (65)

- High-Performance Computing (87)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (48)

- Materials (144)

- Materials Science (141)

- Mathematics (9)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (65)

- Net Zero (14)

- Neutron Science (131)

- Nuclear Energy (109)

- Partnerships (46)

- Physics (62)

- Polymers (33)

- Quantum Computing (35)

- Renewable Energy (2)

- Security (24)

- Simulation (49)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (58)

- Sustainable Energy (129)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

Two ORNL teams recently completed Cohort 18 of Energy I-Corps, an immersive two-month training program where the scientists define their technology’s value propositions, conduct stakeholder discovery interviews and develop viable market pathways.

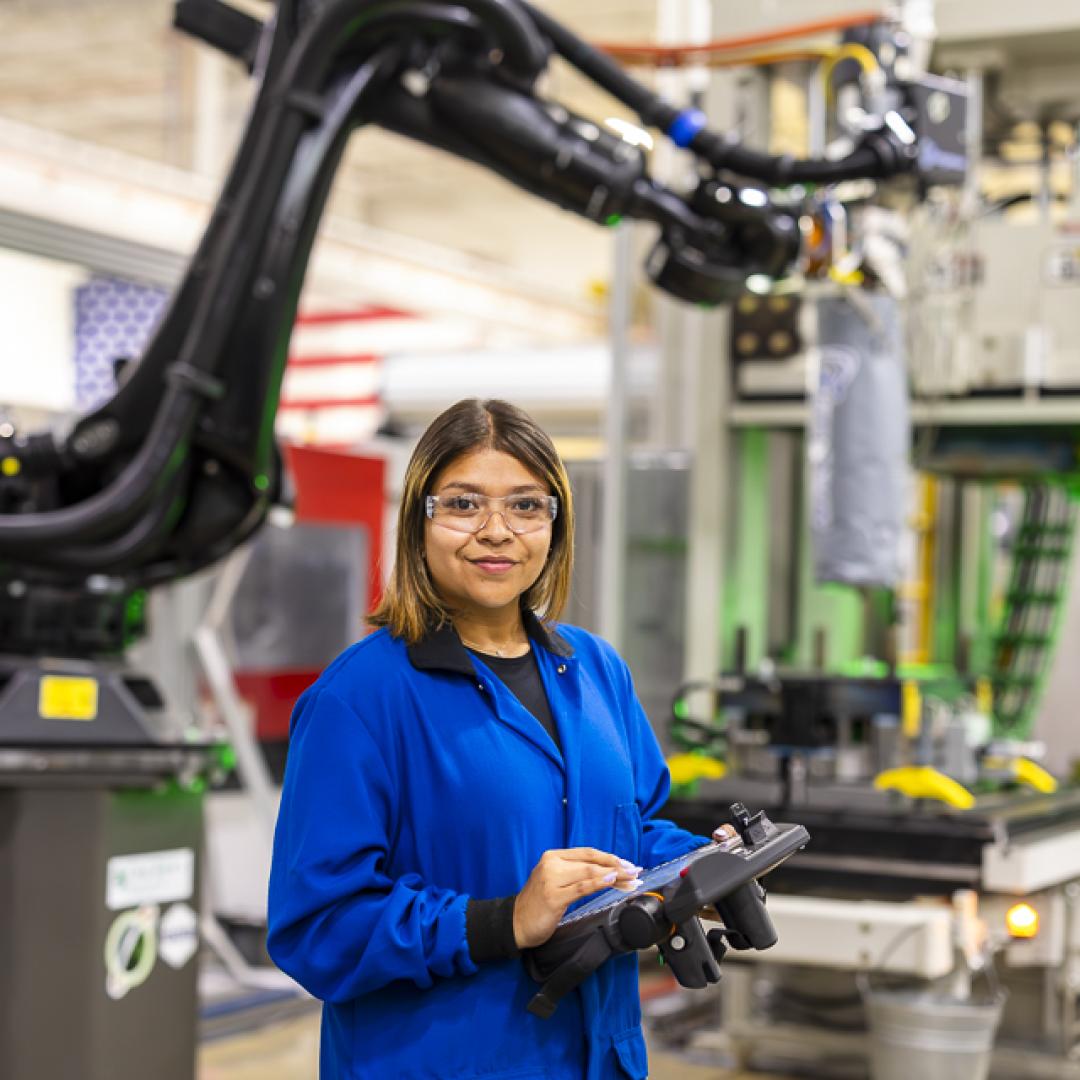

Brittany Rodriguez never imagined she would pursue a science career at a Department of Energy national laboratory. However, after some encouraging words from her mother, input from key mentors at the University of Texas Rio Grande Valley, or UTRGV, and a lot of hard work, Rodriguez landed at DOE’s Manufacturing Demonstration Facility, or MDF, at Oak Ridge National Laboratory.

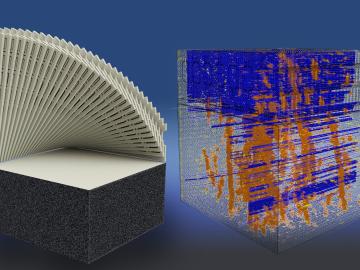

The Department of Energy’s Oak Ridge National Laboratory has publicly released a new set of additive manufacturing data that industry and researchers can use to evaluate and improve the quality of 3D-printed components. The breadth of the datasets can significantly boost efforts to verify the quality of additively manufactured parts using only information gathered during printing, without requiring expensive and time-consuming post-production analysis.

Participants in the SM2ART Research Experience for Undergraduates program got the chance to see what life is like in a research setting. REU participant Brianna Greer studied banana fibers as a reinforcing material in making lightweight parts for cars and bicycles.

Advanced materials research to enable energy-efficient, cost-competitive and environmentally friendly technologies for the United States and Japan is the goal of a memorandum of understanding, or MOU, between the Department of Energy’s Oak Ridge National Laboratory and Japan’s National Institute of Materials Science.

Researchers at ORNL have developed the first additive manufacturing slicing computer application to simultaneously speed and simplify digital conversion of accurate, large-format three-dimensional parts in a factory production setting.

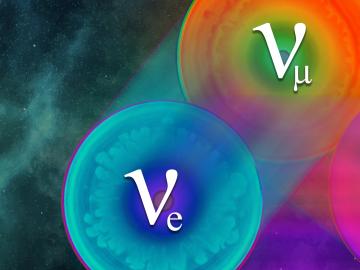

Researchers used quantum simulations to obtain new insights into the nature of neutrinos — the mysterious subatomic particles that abound throughout the universe — and their role in the deaths of massive stars.

Close on the heels of its fourth summer school, the Quantum Science Center, or QSC, hosted its second in-person all-hands meeting in early May. More than 150 scientists, engineers and support staff traveled from 17 institutions to review the QSC’s progress, examine existing priorities and brainstorm new short- and long-term research endeavors.

Researchers at Oak Ridge National Laboratory have developed free data sets to estimate how much energy any building in the contiguous U.S. will use in 2100. These data sets provide planners a way to anticipate future energy needs as the climate changes.

Researchers at ORNL and the University of Maine have designed and 3D-printed a single-piece, recyclable natural-material floor panel tested to be strong enough to replace construction materials like steel.