Filter News

Area of Research

- Advanced Manufacturing (22)

- Biology and Environment (15)

- Building Technologies (1)

- Clean Energy (84)

- Fuel Cycle Science and Technology (1)

- Fusion and Fission (25)

- Fusion Energy (13)

- Isotopes (1)

- Materials (32)

- Materials for Computing (5)

- National Security (37)

- Neutron Science (9)

- Nuclear Science and Technology (12)

- Supercomputing (15)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (124)

- (-) Fusion (55)

- (-) National Security (65)

- (-) Software (1)

- Advanced Reactors (34)

- Artificial Intelligence (94)

- Big Data (57)

- Bioenergy (92)

- Biology (100)

- Biomedical (59)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (66)

- Clean Water (30)

- Climate Change (101)

- Composites (28)

- Computer Science (192)

- Coronavirus (46)

- Critical Materials (27)

- Cybersecurity (35)

- Decarbonization (80)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (109)

- Environment (196)

- Exascale Computing (38)

- Fossil Energy (6)

- Frontier (43)

- Grid (65)

- High-Performance Computing (87)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (48)

- Materials (144)

- Materials Science (141)

- Mathematics (9)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- Net Zero (14)

- Neutron Science (131)

- Nuclear Energy (109)

- Partnerships (46)

- Physics (62)

- Polymers (33)

- Quantum Computing (35)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (49)

- Space Exploration (25)

- Statistics (3)

- Summit (58)

- Sustainable Energy (129)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

Joe Tuccillo, a human geography research scientist, leads the UrbanPop project that uses census data to create synthetic populations. Using a Python software suite called Likeness on ORNL’s high-performance computers, Tuccillo’s team generates a population with individual ‘agents’ designed to represent people that interact with other agents, facilities and services in a simulated neighborhood.

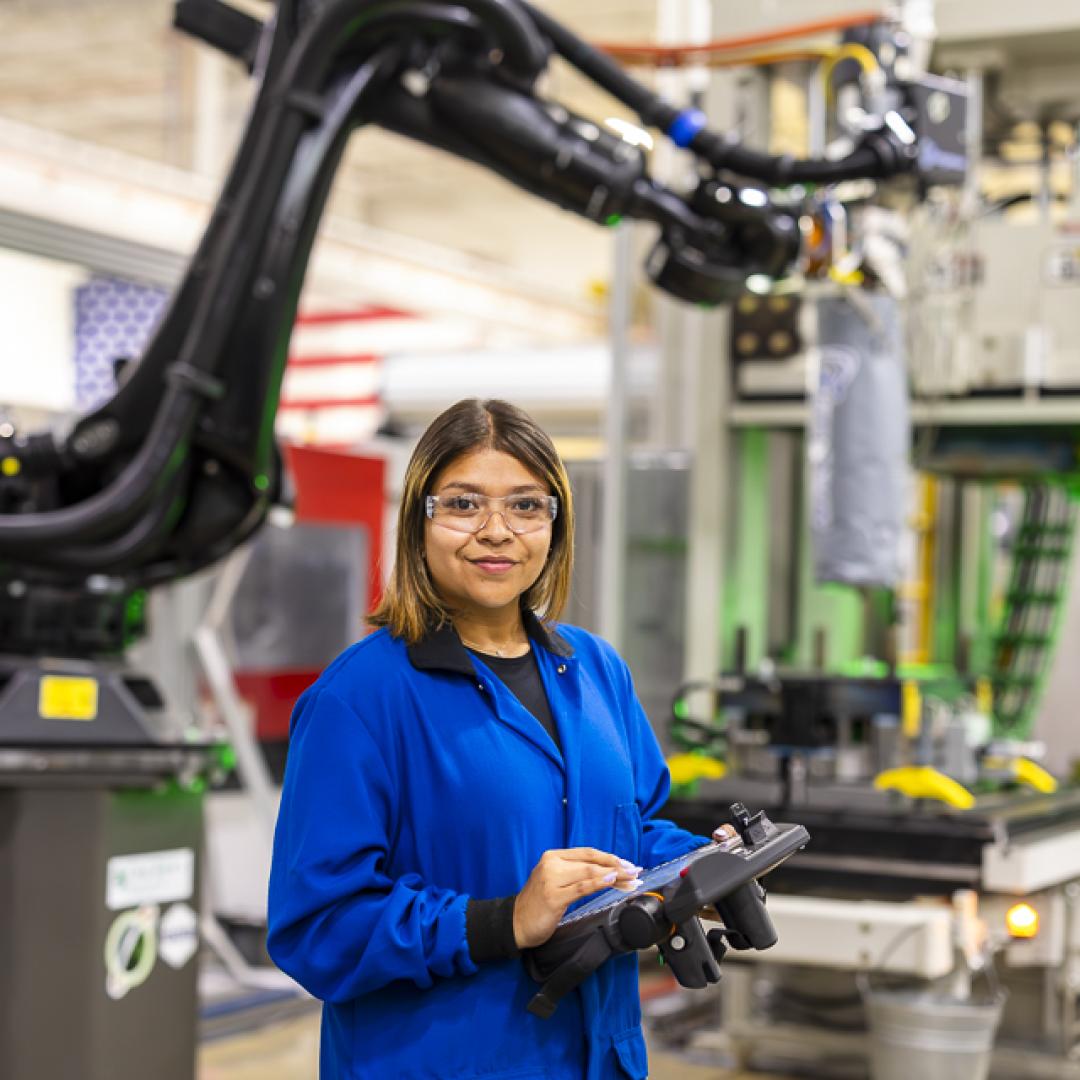

Brittany Rodriguez never imagined she would pursue a science career at a Department of Energy national laboratory. However, after some encouraging words from her mother, input from key mentors at the University of Texas Rio Grande Valley, or UTRGV, and a lot of hard work, Rodriguez landed at DOE’s Manufacturing Demonstration Facility, or MDF, at Oak Ridge National Laboratory.

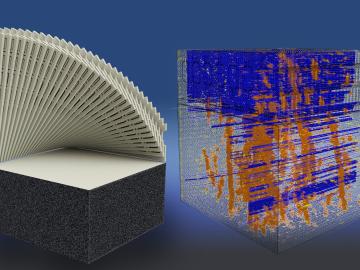

The Department of Energy’s Oak Ridge National Laboratory has publicly released a new set of additive manufacturing data that industry and researchers can use to evaluate and improve the quality of 3D-printed components. The breadth of the datasets can significantly boost efforts to verify the quality of additively manufactured parts using only information gathered during printing, without requiring expensive and time-consuming post-production analysis.

ORNL hosted the Mid-South Regional Chapter of the American Society for Photogrammetry and Remote Sensing, or ASPRS. Participants spanning government, academia and industry engaged in talks, poster sessions, events and workshops to further scientific discovery in a field devoted to using pictures to understand changes to the earth’s inhabitants and landscape.

A newly established internship between ORNL and Maryville College is bringing cybersecurity careers to a local liberal arts college. The internship was established by a Maryville College alumni who recently joined ORNL.

Oak Ridge National Laboratory has named Troy A. Carter director of the Fusion Energy Division in ORNL’s Fusion and Fission Energy and Science Directorate, or FFESD.

As a data scientist, Daniel Adams uses storytelling to parse through a large amount of information to determine which elements are most important, paring down the data to result in the most efficient and accurate data set possible.

Participants in the SM2ART Research Experience for Undergraduates program got the chance to see what life is like in a research setting. REU participant Brianna Greer studied banana fibers as a reinforcing material in making lightweight parts for cars and bicycles.

Advanced materials research to enable energy-efficient, cost-competitive and environmentally friendly technologies for the United States and Japan is the goal of a memorandum of understanding, or MOU, between the Department of Energy’s Oak Ridge National Laboratory and Japan’s National Institute of Materials Science.

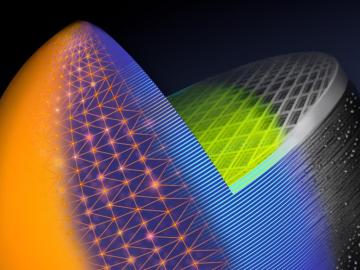

Researchers at ORNL have developed the first additive manufacturing slicing computer application to simultaneously speed and simplify digital conversion of accurate, large-format three-dimensional parts in a factory production setting.