Filter News

Area of Research

- Advanced Manufacturing (22)

- Biology and Environment (23)

- Building Technologies (1)

- Clean Energy (86)

- Computer Science (1)

- Fusion and Fission (5)

- Fusion Energy (1)

- Materials (50)

- Materials for Computing (8)

- National Security (3)

- Neutron Science (9)

- Nuclear Science and Technology (4)

- Quantum information Science (2)

- Supercomputing (34)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (121)

- (-) Exascale Computing (37)

- (-) Microscopy (51)

- (-) Renewable Energy (2)

- Advanced Reactors (34)

- Artificial Intelligence (91)

- Big Data (53)

- Bioenergy (91)

- Biology (98)

- Biomedical (58)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (63)

- Clean Water (29)

- Climate Change (99)

- Composites (26)

- Computer Science (187)

- Coronavirus (46)

- Critical Materials (26)

- Cybersecurity (35)

- Decarbonization (79)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (108)

- Environment (194)

- Fossil Energy (5)

- Frontier (42)

- Fusion (54)

- Grid (62)

- High-Performance Computing (84)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (47)

- Materials (144)

- Materials Science (140)

- Mathematics (7)

- Mercury (12)

- Microelectronics (3)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (61)

- Net Zero (13)

- Neutron Science (131)

- Nuclear Energy (108)

- Partnerships (44)

- Physics (61)

- Polymers (33)

- Quantum Computing (34)

- Quantum Science (69)

- Security (24)

- Simulation (47)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Sustainable Energy (125)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

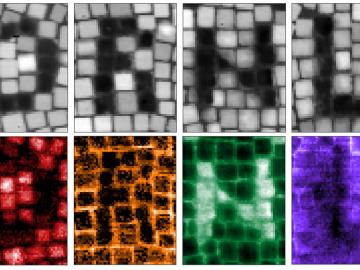

Researchers at ORNL are teaching microscopes to drive discoveries with an intuitive algorithm, developed at the lab’s Center for Nanophase Materials Sciences, that could guide breakthroughs in new materials for energy technologies, sensing and computing.

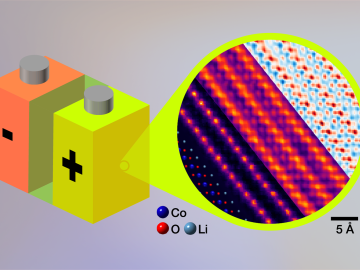

Oak Ridge National Laboratory researchers demonstrated an electron microscopy technique for imaging lithium in energy storage materials, such as lithium ion batteries, at the atomic scale.

When Andrew Sutton arrived at ORNL in late 2020, he knew the move would be significant in more ways than just a change in location.

A force within the supercomputing community, Jack Dongarra developed software packages that became standard in the industry, allowing high-performance computers to become increasingly more powerful in recent decades.

Oak Ridge National Laboratory scientist Amy Elliott is one of 120 women featured in a new exhibit, IfThenSheCan, at the Smithsonian to commemorate Women's History Month. A life-size 3D printed statue of Elliott, a manufacturing scientist, is on display in the Smithsonian Castle in Washington, D.C.

Surrounded by the mountains of landlocked Tennessee, Oak Ridge National Laboratory’s Teri O’Meara is focused on understanding the future of the vitally important ecosystems lining the nation’s coasts.

ORNL, TVA and TNECD were recognized by the Federal Laboratory Consortium for their impactful partnership that resulted in a record $2.3 billion investment by Ultium Cells, a General Motors and LG Energy Solution joint venture, to build a battery cell manufacturing plant in Spring Hill, Tennessee.

Bruce Warmack has been fascinated by science since his mother finally let him have a chemistry set at the age of nine. He’d been pestering her for one since he was six.

Oak Ridge National Laboratory researchers recently used large-scale additive manufacturing with metal to produce a full-strength steel component for a wind turbine, proving the technique as a viable alternative to

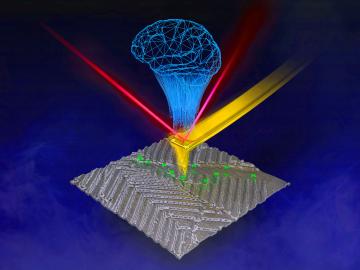

Drilling with the beam of an electron microscope, scientists at ORNL precisely machined tiny electrically conductive cubes that can interact with light and organized them in patterned structures that confine and relay light’s electromagnetic signal.