Filter News

Area of Research

- Advanced Manufacturing (22)

- Biology and Environment (27)

- Biology and Soft Matter (1)

- Building Technologies (1)

- Clean Energy (150)

- Fusion and Fission (9)

- Fusion Energy (1)

- Materials (61)

- Materials for Computing (12)

- National Security (6)

- Neutron Science (13)

- Nuclear Science and Technology (4)

- Renewable Energy (1)

- Supercomputing (15)

- Transportation Systems (2)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (121)

- (-) Chemical Sciences (63)

- (-) Hydropower (11)

- (-) Transportation (97)

- Advanced Reactors (34)

- Artificial Intelligence (91)

- Big Data (53)

- Bioenergy (91)

- Biology (98)

- Biomedical (58)

- Biotechnology (22)

- Buildings (57)

- Clean Water (29)

- Climate Change (99)

- Composites (26)

- Computer Science (187)

- Coronavirus (46)

- Critical Materials (26)

- Cybersecurity (35)

- Decarbonization (79)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (108)

- Environment (194)

- Exascale Computing (37)

- Fossil Energy (5)

- Frontier (42)

- Fusion (54)

- Grid (62)

- High-Performance Computing (84)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (47)

- Materials (144)

- Materials Science (140)

- Mathematics (7)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (61)

- Net Zero (13)

- Neutron Science (131)

- Nuclear Energy (108)

- Partnerships (44)

- Physics (61)

- Polymers (33)

- Quantum Computing (34)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (47)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Sustainable Energy (125)

- Transformational Challenge Reactor (7)

Media Contacts

Researchers at ORNL have developed an online tool that offers industrial plants an easier way to track and download information about their energy footprint and carbon emissions.

ORNL has provided hydropower operators with new data to better prepare for extreme weather events and shifts in seasonal energy demands caused by climate change.

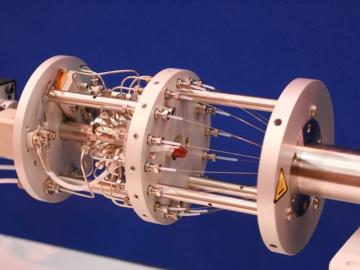

When Bill Partridge started working with industry partner Cummins in 1997, he was a postdoctoral researcher specializing in applied optical diagnostics and new to Oak Ridge National Laboratory.

Five technologies invented by scientists at the Department of Energy’s Oak Ridge National Laboratory have been selected for targeted investment through ORNL’s Technology Innovation Program.

To further the potential benefits of the nation’s hydropower resources, researchers at Oak Ridge National Laboratory have developed and maintain a comprehensive water energy digital platform called HydroSource.

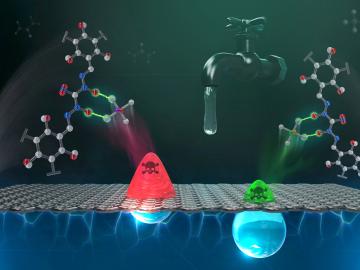

Researchers at ORNL are tackling a global water challenge with a unique material designed to target not one, but two toxic, heavy metal pollutants for simultaneous removal.

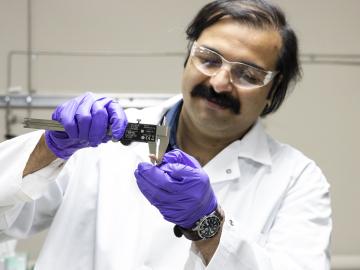

Chemical and environmental engineer Samarthya Bhagia is focused on achieving carbon neutrality and a circular economy by designing new plant-based materials for a range of applications from energy storage devices and sensors to environmentally friendly bioplastics.

Although more than 92,000 dams populate the country, the vast majority — about 89,000 — do not generate electricity through hydropower.

Burak Ozpineci, a Corporate Fellow and section head for Vehicle and Mobility Systems Research at Oak Ridge National Laboratory, is one of six international recipients of the eighth Nagamori Award.

ORNL researchers have developed an upcycling approach that adds value to discarded plastics for reuse in additive manufacturing, or 3D printing.