Filter News

Area of Research

- Advanced Manufacturing (22)

- Biology and Environment (15)

- Building Technologies (4)

- Clean Energy (114)

- Computer Science (1)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (1)

- Fusion and Fission (7)

- Fusion Energy (2)

- Materials (35)

- Materials for Computing (4)

- National Security (8)

- Neutron Science (7)

- Nuclear Science and Technology (4)

- Supercomputing (37)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (121)

- (-) Buildings (57)

- (-) Frontier (42)

- (-) Partnerships (44)

- Advanced Reactors (34)

- Artificial Intelligence (91)

- Big Data (53)

- Bioenergy (91)

- Biology (98)

- Biomedical (58)

- Biotechnology (22)

- Chemical Sciences (63)

- Clean Water (29)

- Climate Change (99)

- Composites (26)

- Computer Science (187)

- Coronavirus (46)

- Critical Materials (26)

- Cybersecurity (35)

- Decarbonization (79)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (108)

- Environment (194)

- Exascale Computing (37)

- Fossil Energy (5)

- Fusion (54)

- Grid (62)

- High-Performance Computing (84)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (47)

- Materials (144)

- Materials Science (140)

- Mathematics (7)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (61)

- Net Zero (13)

- Neutron Science (131)

- Nuclear Energy (108)

- Physics (61)

- Polymers (33)

- Quantum Computing (34)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (47)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Sustainable Energy (125)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

Susan Hubbard, diputada de Ciencia y Tecnología en ORNL, Can (John) Saygin, vicepresidente mayor de investigación y decano del Colegio de la Escuela de Postgrados en UTGRV, firman un Memorándum de Entendimiento comprometiéndose a fortalecer

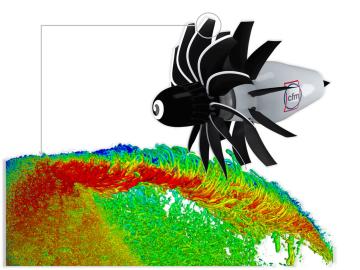

As Frontier, the world’s first exascale supercomputer, was being assembled at the Oak Ridge Leadership Computing Facility in 2021, understanding its performance on mixed-precision calculations remained a difficult prospect.

The common sounds in the background of daily life – like a refrigerator’s hum, an air conditioner’s whoosh and a heat pump’s buzz – often go unnoticed. These noises, however, are the heartbeat of a healthy building and integral for comfort and convenience.

Oak Ridge National Laboratory researchers have conducted a comprehensive life cycle, cost and carbon emissions analysis on 3D-printed molds for precast concrete and determined the method is economically beneficial compared to conventional wood molds.

ORNL has launched a new entrepreneurial start-up program, Safari, as an addition to DOE's Office of Technology Transitions Practices to Accelerate the Commercialization of Technologies program. Safari seeks to connect post-exit entrepreneurs with commercially relevant technologies developed by world-leading scientific experts, which could provide the basis for a new business.

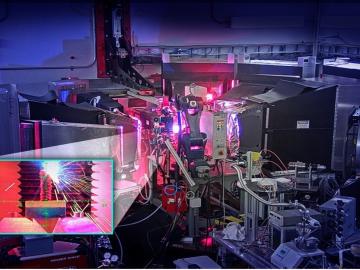

The Department of Energy’s Office of Science has selected three ORNL research teams to receive funding through DOE’s new Biopreparedness Research Virtual Environment initiative.

Outside the high-performance computing, or HPC, community, exascale may seem more like fodder for science fiction than a powerful tool for scientific research. Yet, when seen through the lens of real-world applications, exascale computing goes from ethereal concept to tangible reality with exceptional benefits.

Researchers at the Department of Energy’s Oak Ridge National Laboratory have created a new detection system that allows home energy auditors to see air leaking from a building in real time with the help of a camera.

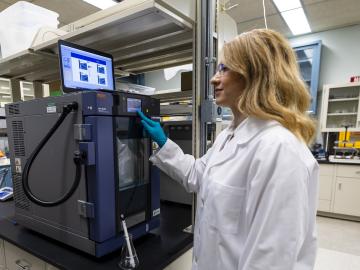

A licensing agreement between the Department of Energy’s Oak Ridge National Laboratory and research partner ZEISS will enable industrial X-ray computed tomography, or CT, to perform rapid evaluations of 3D-printed components using ORNL’s machine

Technologies developed by researchers at ORNL have received six 2023 R&D 100 Awards.