Filter News

Area of Research

- Advanced Manufacturing (22)

- Biology and Environment (14)

- Building Technologies (1)

- Clean Energy (90)

- Computational Biology (1)

- Electricity and Smart Grid (1)

- Fuel Cycle Science and Technology (1)

- Fusion and Fission (28)

- Fusion Energy (10)

- Isotope Development and Production (1)

- Isotopes (3)

- Materials (67)

- Materials for Computing (9)

- National Security (11)

- Neutron Science (103)

- Nuclear Science and Technology (39)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Supercomputing (20)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (122)

- (-) Microelectronics (3)

- (-) Neutron Science (131)

- (-) Nuclear Energy (109)

- Advanced Reactors (34)

- Artificial Intelligence (91)

- Big Data (55)

- Bioenergy (92)

- Biology (99)

- Biomedical (58)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (65)

- Clean Water (29)

- Climate Change (100)

- Composites (26)

- Computer Science (189)

- Coronavirus (46)

- Critical Materials (26)

- Cybersecurity (35)

- Decarbonization (80)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (109)

- Environment (195)

- Exascale Computing (37)

- Fossil Energy (6)

- Frontier (42)

- Fusion (55)

- Grid (63)

- High-Performance Computing (85)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (48)

- Materials (144)

- Materials Science (141)

- Mathematics (9)

- Mercury (12)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (63)

- Net Zero (14)

- Partnerships (44)

- Physics (61)

- Polymers (33)

- Quantum Computing (34)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (48)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Sustainable Energy (126)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

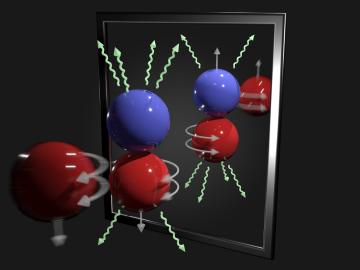

A team of scientists has for the first time measured the elusive weak interaction between protons and neutrons in the nucleus of an atom. They had chosen the simplest nucleus consisting of one neutron and one proton for the study.

Scientists at the Department of Energy’s Oak Ridge National Laboratory have created a recipe for a renewable 3D printing feedstock that could spur a profitable new use for an intractable biorefinery byproduct: lignin.

More than 70 years ago, United States Navy Captain Hyman Rickover learned the ins and outs of nuclear science and reactor technology at the Clinton Training School at what would eventually become the Department of Energy’s Oak Ridge National Laboratory. Rickover applied his knowl...

![2018-P07635 BL-6 user - Univ of Guelph-6004R_sm[2].jpg 2018-P07635 BL-6 user - Univ of Guelph-6004R_sm[2].jpg](/sites/default/files/styles/list_page_thumbnail/public/2018-P07635%20BL-6%20user%20-%20Univ%20of%20Guelph-6004R_sm%5B2%5D.jpg?itok=DUdZNt_q)

A team of scientists, led by University of Guelph professor John Dutcher, are using neutrons at ORNL’s Spallation Neutron Source to unlock the secrets of natural nanoparticles that could be used to improve medicines.

Scientists from Oak Ridge National Laboratory performed a corrosion test in a neutron radiation field to support the continued development of molten salt reactors.

Two leaders in US manufacturing innovation, Thomas Kurfess and Scott Smith, are joining the Department of Energy’s Oak Ridge National Laboratory to support its pioneering research in advanced manufacturing.

The Spallation Neutron Source at the Department of Energy’s Oak Ridge National Laboratory has broken a new record by ending its first neutron production cycle in fiscal year 2019 at its design power level of 1.4 megawatts.

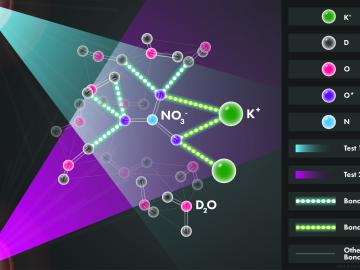

Scientists at the Department of Energy’s Oak Ridge National Laboratory used neutrons, isotopes and simulations to “see” the atomic structure of a saturated solution and found evidence supporting one of two competing hypotheses about how ions come

If you ask the staff and researchers at the Department of Energy’s Oak Ridge National Laboratory how they were first referred to the lab, you will get an extremely varied list of responses. Some may have come here as student interns, some grew up in the area and knew the lab by ...

The United Kingdom’s National Nuclear Laboratory and the U.S. Department of Energy’s Oak Ridge National Laboratory have agreed to cooperate on a wide range of nuclear energy research and development efforts that leverage both organizations’ unique expertise and capabilities.