Filter News

Area of Research

- Advanced Manufacturing (22)

- Biology and Environment (11)

- Building Technologies (4)

- Clean Energy (110)

- Computer Science (1)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (1)

- Fusion and Fission (5)

- Fusion Energy (1)

- Isotope Development and Production (1)

- Isotopes (4)

- Materials (28)

- Materials for Computing (5)

- National Security (3)

- Neutron Science (9)

- Nuclear Science and Technology (9)

- Supercomputing (12)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (121)

- (-) Buildings (57)

- (-) Space Exploration (25)

- Advanced Reactors (34)

- Artificial Intelligence (91)

- Big Data (53)

- Bioenergy (91)

- Biology (98)

- Biomedical (58)

- Biotechnology (22)

- Chemical Sciences (63)

- Clean Water (29)

- Climate Change (99)

- Composites (26)

- Computer Science (187)

- Coronavirus (46)

- Critical Materials (26)

- Cybersecurity (35)

- Decarbonization (79)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (108)

- Environment (194)

- Exascale Computing (37)

- Fossil Energy (5)

- Frontier (42)

- Fusion (54)

- Grid (62)

- High-Performance Computing (84)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (47)

- Materials (144)

- Materials Science (140)

- Mathematics (7)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (61)

- Net Zero (13)

- Neutron Science (131)

- Nuclear Energy (108)

- Partnerships (44)

- Physics (61)

- Polymers (33)

- Quantum Computing (34)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (47)

- Software (1)

- Statistics (3)

- Summit (57)

- Sustainable Energy (125)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

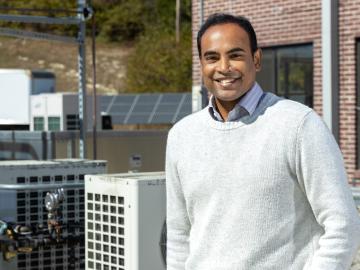

Cheekatamarla is a researcher in the Multifunctional Equipment Integration group with previous experience in product deployment. He is researching alternative energy sources such as hydrogen for cookstoves and his research supports the decarbonization of building technologies.

Rishi Pillai and his research team from ORNL will receive a Best Paper award from the American Society of Mechanical Engineers International Gas Turbine Institute in June at the Turbo Expo 2024 in London.

The Society of Manufacturing Engineers has honored three Oak Ridge National Laboratory researchers with the 2024 SME Susan Smyth Outstanding Young Manufacturing Engineer Award.

ORNL’s Erin Webb is co-leading a new Circular Bioeconomy Systems Convergent Research Initiative focused on advancing production and use of renewable carbon from Tennessee to meet societal needs.

Shift Thermal, a member of Innovation Crossroads’ first cohort of fellows, is commercializing advanced ice thermal energy storage for HVAC, shifting the cooling process to be more sustainable, cost-effective and resilient. Shift Thermal wants to enable a lower-cost, more-efficient thermal energy storage method to provide long-duration resilient cooling when the electric grid is down.

Three ORNL intellectual property projects with industry partners have advanced in DOE's Office of Technology Transitions Making Advanced Technology Commercialization Harmonized, or Lab MATCH, prize, which encourages entrepreneurs to find actionable pathways that bring lab-developed intellectual property to market.

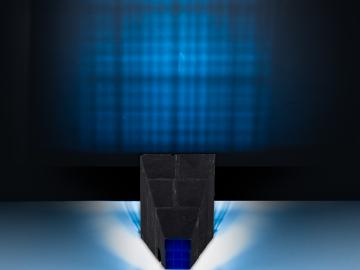

Scientists at ORNL have developed 3-D-printed collimator techniques that can be used to custom design collimators that better filter out noise during different types of neutron scattering experiments

ORNL scientists have determined how to avoid costly and potentially irreparable damage to large metallic parts fabricated through additive manufacturing, also known as 3D printing, that is caused by residual stress in the material.

Canan Karakaya, a R&D Staff member in the Chemical Process Scale-Up group at ORNL, was inspired to become a chemical engineer after she experienced a magical transformation that turned ammonia gas into ammonium nitrate, turning a liquid into white flakes gently floating through the air.

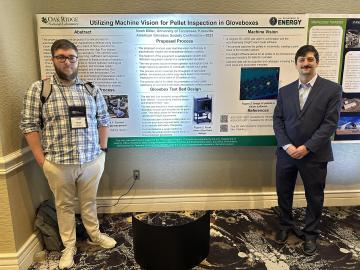

College intern Noah Miller is on his 3rd consecutive internship at ORNL, currently working on developing an automated pellet inspection system for Oak Ridge National Laboratory’s Plutonium-238 Supply Program. Along with his success at ORNL, Miller is also focusing on becoming a mentor for kids, giving back to the place where he discovered his passion and developed his skills.