Filter News

Area of Research

- Advanced Manufacturing (23)

- Biology and Environment (30)

- Building Technologies (1)

- Clean Energy (103)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (2)

- Fusion and Fission (5)

- Fusion Energy (2)

- Isotopes (4)

- Materials (96)

- Materials Characterization (2)

- Materials for Computing (13)

- Materials Under Extremes (1)

- National Security (5)

- Neutron Science (18)

- Nuclear Science and Technology (4)

- Supercomputing (24)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (121)

- (-) Biotechnology (22)

- (-) Critical Materials (26)

- (-) Materials (144)

- Advanced Reactors (34)

- Artificial Intelligence (91)

- Big Data (53)

- Bioenergy (91)

- Biology (98)

- Biomedical (58)

- Buildings (57)

- Chemical Sciences (63)

- Clean Water (29)

- Climate Change (99)

- Composites (26)

- Computer Science (187)

- Coronavirus (46)

- Cybersecurity (35)

- Decarbonization (79)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (108)

- Environment (194)

- Exascale Computing (37)

- Fossil Energy (5)

- Frontier (42)

- Fusion (54)

- Grid (62)

- High-Performance Computing (84)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (47)

- Materials Science (140)

- Mathematics (7)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (61)

- Net Zero (13)

- Neutron Science (131)

- Nuclear Energy (108)

- Partnerships (44)

- Physics (61)

- Polymers (33)

- Quantum Computing (34)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (47)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Sustainable Energy (125)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

The United States could triple its current bioeconomy by producing more than 1 billion tons per year of plant-based biomass for renewable fuels, while meeting projected demands for food, feed, fiber, conventional forest products and exports, according to the DOE’s latest Billion-Ton Report led by ORNL.

Ilenne Del Valle is merging her expertise in synthetic biology and environmental science to develop new technologies to help scientists better understand and engineer ecosystems for climate resilience.

ORNL’s Janet Meier won the Energy Security category of the U.S. Department of Energy’s inaugural National Lab Research SLAM on Capitol Hill.

Rigoberto “Gobet” Advincula, a scientist at the Department of Energy’s Oak Ridge National Laboratory, has been appointed a Fellow of the Institute of Materials, Minerals and Mining.

Corning uses neutron scattering to study the stability of different types of glass. Recently, researchers for the company have found that understanding the stability of the rings of atoms in glass materials can help predict the performance of glass products.

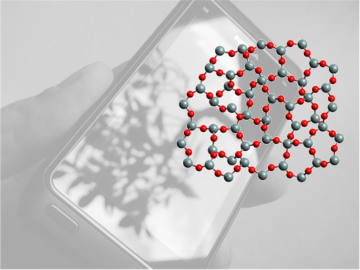

Scientists at ORNL have developed a technique for recovering and recycling critical materials that has garnered special recognition from a peer-reviewed materials journal and received a new phase of funding for research and development.

Rigoberto “Gobet” Advincula, a scientist at the Department of Energy’s Oak Ridge National Laboratory, has been named a 2023 Fellow of the National Academy of Inventors. Advincula has been recognized for his 14 patents and 21 published filings related to nanomaterials, smart coatings and films, solid-state device fabrication and chemical additives.

It would be a challenge for any scientist to match Alexey Serov’s rate of inventions related to green hydrogen fuel. But this researcher at ORNL has 84 patents with at least 35 more under review, so his electrifying pace is unlikely to slow down any time soon.

Ateios Systems licensed an ORNL technology for solvent-free battery component production using electron curing. Through Innovation Crossroads, Ateios continues to work with ORNL to enable readiness for production-quality battery components.

Researchers at ORNL became the first to 3D-print large rotating steam turbine blades for generating energy in power plants.