Filter News

Area of Research

News Topics

- (-) 3-D Printing/Advanced Manufacturing (116)

- (-) Critical Materials (24)

- (-) Net Zero (12)

- Advanced Reactors (34)

- Artificial Intelligence (87)

- Big Data (50)

- Bioenergy (88)

- Biology (96)

- Biomedical (58)

- Biotechnology (21)

- Buildings (55)

- Chemical Sciences (60)

- Clean Water (29)

- Climate Change (94)

- Composites (25)

- Computer Science (184)

- Coronavirus (46)

- Cybersecurity (35)

- Decarbonization (75)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (107)

- Environment (192)

- Exascale Computing (36)

- Fossil Energy (5)

- Frontier (41)

- Fusion (53)

- Grid (61)

- High-Performance Computing (83)

- Hydropower (11)

- Irradiation (3)

- Isotopes (49)

- ITER (7)

- Machine Learning (46)

- Materials (140)

- Materials Science (135)

- Mathematics (6)

- Mercury (12)

- Microelectronics (2)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (59)

- Neutron Science (130)

- Nuclear Energy (105)

- Partnerships (40)

- Physics (59)

- Polymers (31)

- Quantum Computing (31)

- Quantum Science (66)

- Renewable Energy (2)

- Security (24)

- Simulation (45)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Sustainable Energy (120)

- Transformational Challenge Reactor (7)

- Transportation (94)

Media Contacts

The United States could triple its current bioeconomy by producing more than 1 billion tons per year of plant-based biomass for renewable fuels, while meeting projected demands for food, feed, fiber, conventional forest products and exports, according to the DOE’s latest Billion-Ton Report led by ORNL.

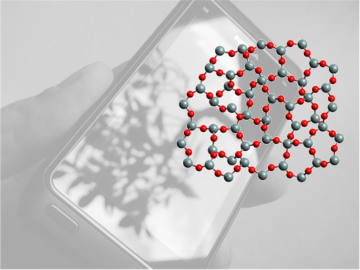

Corning uses neutron scattering to study the stability of different types of glass. Recently, researchers for the company have found that understanding the stability of the rings of atoms in glass materials can help predict the performance of glass products.

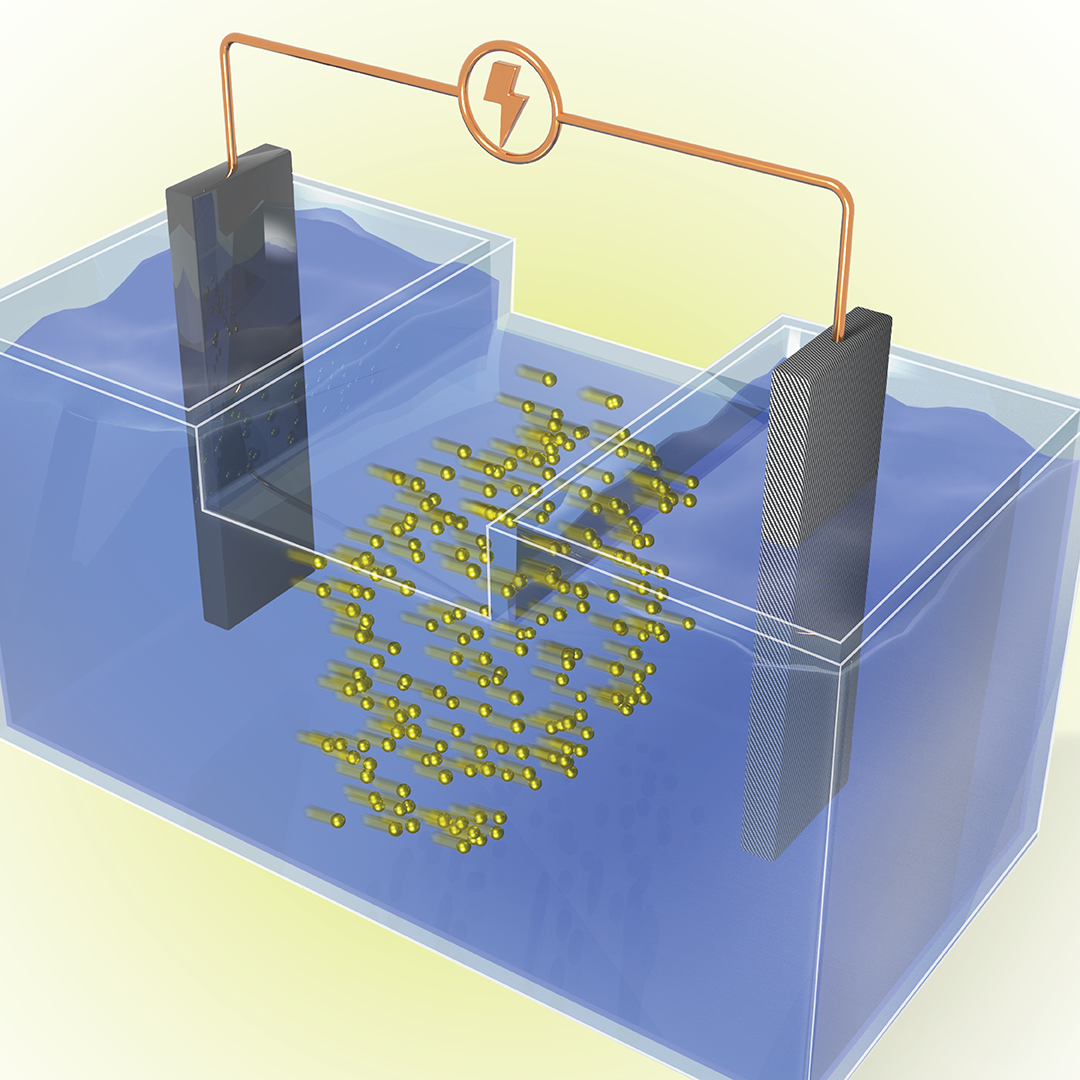

It would be a challenge for any scientist to match Alexey Serov’s rate of inventions related to green hydrogen fuel. But this researcher at ORNL has 84 patents with at least 35 more under review, so his electrifying pace is unlikely to slow down any time soon.

Researchers at ORNL became the first to 3D-print large rotating steam turbine blades for generating energy in power plants.

Scientists from more than a dozen institutions have completed a first-of-its-kind high-resolution assessment of carbon dioxide removal potential in the United States, charting a path to achieve a net-zero greenhouse gas economy by 2050.

Nuclear engineering students from the United States Military Academy and United States Naval Academy are working with researchers at ORNL to complete design concepts for a nuclear propulsion rocket to go to space in 2027 as part of the Defense Advanced Research Projects Agency DRACO program.

Four scientists affiliated with ORNL were named Battelle Distinguished Inventors during the lab’s annual Innovation Awards on Dec. 1 in recognition of being granted 14 or more United States patents.

Caldera Holding, the owner and developer of Missouri’s Pea Ridge iron mine, has entered a nonexclusive research and development licensing agreement with ORNL to apply a membrane solvent extraction technique, or MSX, developed by ORNL researchers to mined ores.

The Hub & Spoke Sustainable Materials & Manufacturing Alliance for Renewable Technologies, or SM2ART, program has been honored with the composites industry’s Combined Strength Award at the Composites and Advanced Materials Expo, or CAMX, 2023 in Atlanta. This distinction goes to the team that applies their knowledge, resources and talent to solve a problem by making the best use of composites materials.

An Oak Ridge National Laboratory-developed advanced manufacturing technology, AMCM, was recently licensed by Orbital Composites and enables the rapid production of composite-based components, which could accelerate the decarbonization of vehicles