Filter News

Area of Research

- Advanced Manufacturing (3)

- Biological Systems (1)

- Biology and Environment (24)

- Clean Energy (85)

- Computational Biology (2)

- Computational Engineering (1)

- Fusion and Fission (4)

- Isotopes (5)

- Materials (27)

- Materials for Computing (8)

- National Security (4)

- Neutron Science (17)

- Nuclear Science and Technology (2)

- Supercomputing (23)

- Transportation Systems (2)

News Topics

- (-) Biomedical (59)

- (-) Composites (29)

- (-) Transportation (97)

- 3-D Printing/Advanced Manufacturing (125)

- Advanced Reactors (34)

- Artificial Intelligence (95)

- Big Data (58)

- Bioenergy (92)

- Biology (100)

- Biotechnology (23)

- Buildings (59)

- Chemical Sciences (68)

- Clean Water (30)

- Climate Change (101)

- Computer Science (194)

- Coronavirus (46)

- Critical Materials (28)

- Cybersecurity (35)

- Decarbonization (81)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (110)

- Environment (197)

- Exascale Computing (39)

- Fossil Energy (6)

- Frontier (44)

- Fusion (55)

- Grid (65)

- High-Performance Computing (88)

- Hydropower (11)

- Irradiation (3)

- Isotopes (54)

- ITER (7)

- Machine Learning (48)

- Materials (144)

- Materials Science (143)

- Mathematics (9)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (67)

- Net Zero (14)

- Neutron Science (132)

- Nuclear Energy (110)

- Partnerships (49)

- Physics (63)

- Polymers (33)

- Quantum Computing (35)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (49)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (59)

- Sustainable Energy (129)

- Transformational Challenge Reactor (7)

Media Contacts

Seven entrepreneurs comprise the next cohort of Innovation Crossroads, a DOE Lab-Embedded Entrepreneurship Program node based at ORNL. The program provides energy-related startup founders from across the nation with access to ORNL’s unique scientific resources and capabilities, as well as connect them with experts, mentors and networks to accelerate their efforts to take their world-changing ideas to the marketplace.

Two ORNL teams recently completed Cohort 18 of Energy I-Corps, an immersive two-month training program where the scientists define their technology’s value propositions, conduct stakeholder discovery interviews and develop viable market pathways.

Brian Sanders is focused on impactful, multidisciplinary science at Oak Ridge National Laboratory, developing solutions for everything from improved imaging of plant-microbe interactions that influence ecosystem health to advancing new treatments for cancer and viral infections.

Brittany Rodriguez never imagined she would pursue a science career at a Department of Energy national laboratory. However, after some encouraging words from her mother, input from key mentors at the University of Texas Rio Grande Valley, or UTRGV, and a lot of hard work, Rodriguez landed at DOE’s Manufacturing Demonstration Facility, or MDF, at Oak Ridge National Laboratory.

Bill Partridge, a recently retired distinguished researcher at the U.S. Department of Energy’s Oak Ridge National Laboratory, was recognized by DOE’s Vehicle Technologies Office, or VTO, for leading world-class research in transportation throughout his 25-year career.

Researchers at ORNL have successfully demonstrated the first 270-kW wireless power transfer to a light-duty electric vehicle. The demonstration used a Porsche Taycan and was conducted in collaboration with Volkswagen Group of America using the ORNL-developed polyphase wireless charging system.

Researchers at ORNL and the University of Maine have designed and 3D-printed a single-piece, recyclable natural-material floor panel tested to be strong enough to replace construction materials like steel.

Jinghui Yuan, an R&D staff member in the Applied Research for Mobility Systems group at the Department of Energy’s Oak Ridge National Laboratory, has been elevated to a senior member of the Institute of Electrical and Electronics Engineers.

Robert Wagner, associate laboratory director for ORNL's Energy Science and Technology Directorate, has been selected to receive the George Westinghouse Gold Medal from the American Society of Mechanical Engineers, or ASME. The award recognizes his work to advance state-of-the-art clean power generation systems through research on combustion, fuel technologies and controls.

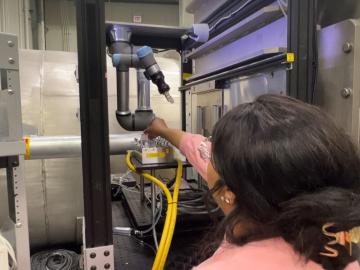

The BIO-SANS instrument, located at Oak Ridge National Laboratory’s High Flux Isotope Reactor, is the latest neutron scattering instrument to be retrofitted with state-of-the-art robotics and custom software. The sophisticated upgrade quadruples the number of samples the instrument can measure automatically and significantly reduces the need for human assistance.