Filter News

Area of Research

- Advanced Manufacturing (2)

- Biological Systems (1)

- Biology and Environment (32)

- Clean Energy (21)

- Computational Biology (2)

- Computational Engineering (1)

- Fusion and Fission (2)

- Isotopes (5)

- Materials (39)

- Materials for Computing (7)

- National Security (7)

- Neutron Science (100)

- Nuclear Science and Technology (7)

- Supercomputing (28)

News Topics

- (-) Biomedical (58)

- (-) Biotechnology (22)

- (-) Neutron Science (131)

- 3-D Printing/Advanced Manufacturing (121)

- Advanced Reactors (34)

- Artificial Intelligence (91)

- Big Data (53)

- Bioenergy (91)

- Biology (98)

- Buildings (57)

- Chemical Sciences (63)

- Clean Water (29)

- Climate Change (99)

- Composites (26)

- Computer Science (187)

- Coronavirus (46)

- Critical Materials (26)

- Cybersecurity (35)

- Decarbonization (79)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (108)

- Environment (194)

- Exascale Computing (37)

- Fossil Energy (5)

- Frontier (42)

- Fusion (54)

- Grid (62)

- High-Performance Computing (84)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (47)

- Materials (144)

- Materials Science (140)

- Mathematics (7)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (61)

- Net Zero (13)

- Nuclear Energy (108)

- Partnerships (44)

- Physics (61)

- Polymers (33)

- Quantum Computing (34)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (47)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Sustainable Energy (125)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

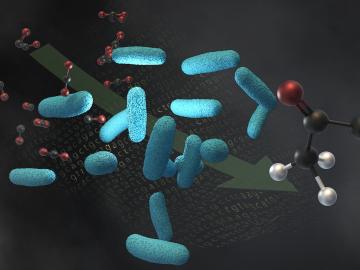

A team of scientists from LanzaTech, Northwestern University and ORNL have developed carbon capture technology that harnesses emissions from industrial processes to produce acetone and isopropanol

Cement trucks entering and exiting the Spallation Neutron Source are a common sight as construction of the VENUS neutron imaging beamline progresses. Slated for completion and commissioning in 2024-2025, VENUS is the twentieth neutron instrument at SNS and will offer many new capabilities.

Three ORNL scientists have been elected fellows of the American Association for the Advancement of Science, or AAAS, the world’s largest general scientific society and publisher of the Science family of journals.

To explore the inner workings of severe acute respiratory syndrome coronavirus 2, or SARS-CoV-2, researchers from ORNL developed a novel technique.

Detecting the activity of CRISPR gene editing tools in organisms with the naked eye and an ultraviolet flashlight is now possible using technology developed at ORNL.

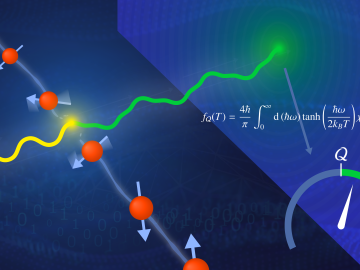

A discovery by Oak Ridge National Laboratory researchers may aid the design of materials that better manage heat.

Energy Secretary Jennifer Granholm visited ORNL on Nov. 22 for a two-hour tour, meeting top scientists and engineers as they highlighted projects and world-leading capabilities that address some of the country’s most complex research and technical challenges.

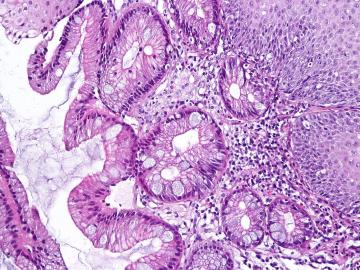

A team including researchers from the Department of Energy’s Oak Ridge National Laboratory has developed a digital tool to better monitor a condition known as Barrett’s esophagus, which affects more than 3 million people in the United States.

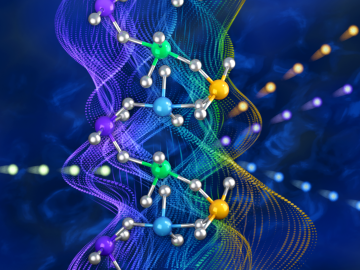

A team led by the U.S. Department of Energy’s Oak Ridge National Laboratory demonstrated the viability of a “quantum entanglement witness” capable of proving the presence of entanglement between magnetic particles, or spins, in a quantum material.

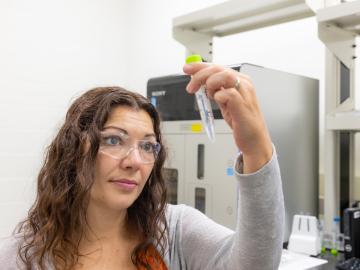

Carrie Eckert applies her skills as a synthetic biologist at ORNL to turn microorganisms into tiny factories that produce a variety of valuable fuels, chemicals and materials for the growing bioeconomy.