Filter News

Area of Research

- Advanced Manufacturing (3)

- Biology and Environment (13)

- Clean Energy (126)

- Computer Science (2)

- Electricity and Smart Grid (1)

- Energy Sciences (1)

- Functional Materials for Energy (2)

- Fusion and Fission (6)

- Isotopes (1)

- Materials (47)

- Materials for Computing (7)

- National Security (4)

- Neutron Science (11)

- Nuclear Science and Technology (4)

- Supercomputing (13)

- Transportation Systems (2)

News Topics

- (-) Composites (26)

- (-) Energy Storage (108)

- (-) Molten Salt (8)

- (-) Transportation (97)

- 3-D Printing/Advanced Manufacturing (119)

- Advanced Reactors (34)

- Artificial Intelligence (91)

- Big Data (53)

- Bioenergy (91)

- Biology (98)

- Biomedical (58)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (63)

- Clean Water (29)

- Climate Change (99)

- Computer Science (187)

- Coronavirus (46)

- Critical Materials (25)

- Cybersecurity (35)

- Decarbonization (79)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Environment (194)

- Exascale Computing (37)

- Fossil Energy (5)

- Frontier (42)

- Fusion (54)

- Grid (62)

- High-Performance Computing (84)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (47)

- Materials (143)

- Materials Science (139)

- Mathematics (7)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Nanotechnology (60)

- National Security (61)

- Net Zero (13)

- Neutron Science (131)

- Nuclear Energy (107)

- Partnerships (43)

- Physics (61)

- Polymers (33)

- Quantum Computing (34)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (47)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Sustainable Energy (125)

- Transformational Challenge Reactor (7)

Media Contacts

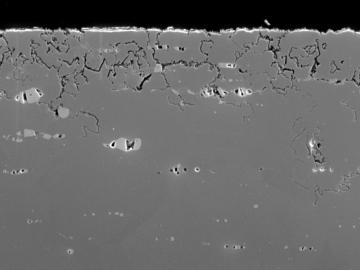

Oak Ridge National Laboratory scientists analyzed more than 50 years of data showing puzzlingly inconsistent trends about corrosion of structural alloys in molten salts and found one factor mattered most—salt purity.

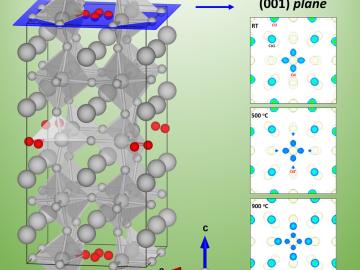

A University of South Carolina research team is investigating the oxygen reduction performance of energy conversion materials called perovskites by using neutron diffraction at Oak Ridge National Laboratory’s Spallation Neutron Source.

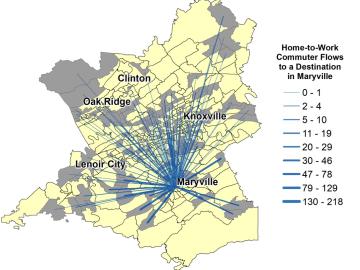

Oak Ridge National Laboratory geospatial scientists who study the movement of people are using advanced machine learning methods to better predict home-to-work commuting patterns.

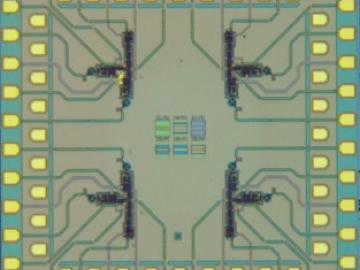

Scientists at Oak Ridge National Laboratory and Hypres, a digital superconductor company, have tested a novel cryogenic, or low-temperature, memory cell circuit design that may boost memory storage while using less energy in future exascale and quantum computing applications.

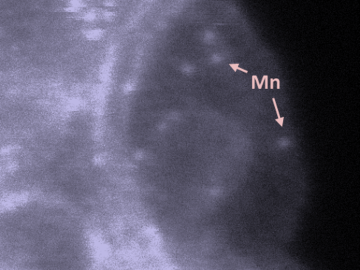

Oak Ridge National Laboratory scientists studying fuel cells as a potential alternative to internal combustion engines used sophisticated electron microscopy to investigate the benefits of replacing high-cost platinum with a lower cost, carbon-nitrogen-manganese-based catalyst.

Scientists at the Department of Energy’s Oak Ridge National Laboratory have created a recipe for a renewable 3D printing feedstock that could spur a profitable new use for an intractable biorefinery byproduct: lignin.

Scientists from Oak Ridge National Laboratory performed a corrosion test in a neutron radiation field to support the continued development of molten salt reactors.

Thought leaders from across the maritime community came together at Oak Ridge National Laboratory to explore the emerging new energy landscape for the maritime transportation system during the Ninth Annual Maritime Risk Symposium.

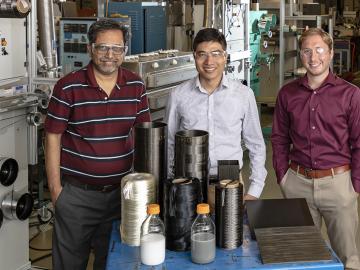

Carbon fiber composites—lightweight and strong—are great structural materials for automobiles, aircraft and other transportation vehicles. They consist of a polymer matrix, such as epoxy, into which reinforcing carbon fibers have been embedded. Because of differences in the mecha...

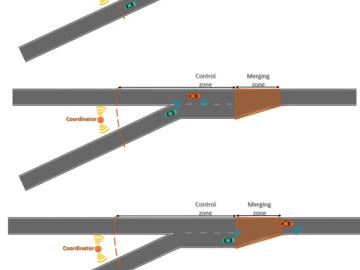

Self-driving cars promise to keep traffic moving smoothly and reduce fuel usage, but proving those advantages has been a challenge with so few connected and automated vehicles, or CAVs, currently on the road.