Filter News

Area of Research

News Topics

- (-) Composites (25)

- (-) Hydropower (11)

- (-) Molten Salt (8)

- 3-D Printing/Advanced Manufacturing (116)

- Advanced Reactors (34)

- Artificial Intelligence (87)

- Big Data (50)

- Bioenergy (88)

- Biology (96)

- Biomedical (58)

- Biotechnology (21)

- Buildings (55)

- Chemical Sciences (60)

- Clean Water (29)

- Climate Change (94)

- Computer Science (184)

- Coronavirus (46)

- Critical Materials (25)

- Cybersecurity (35)

- Decarbonization (75)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (107)

- Environment (192)

- Exascale Computing (36)

- Fossil Energy (5)

- Frontier (41)

- Fusion (53)

- Grid (61)

- High-Performance Computing (83)

- Irradiation (3)

- Isotopes (49)

- ITER (7)

- Machine Learning (46)

- Materials (141)

- Materials Science (136)

- Mathematics (6)

- Mercury (12)

- Microelectronics (2)

- Microscopy (51)

- Nanotechnology (60)

- National Security (59)

- Net Zero (12)

- Neutron Science (130)

- Nuclear Energy (105)

- Partnerships (40)

- Physics (59)

- Polymers (31)

- Quantum Computing (31)

- Quantum Science (66)

- Renewable Energy (2)

- Security (24)

- Simulation (45)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Sustainable Energy (121)

- Transformational Challenge Reactor (7)

- Transportation (94)

Media Contacts

Climate change often comes down to how it affects water, whether it’s for drinking, electricity generation, or how flooding affects people and infrastructure. To better understand these impacts, ORNL water resources engineer Sudershan Gangrade is integrating knowledge ranging from large-scale climate projections to local meteorology and hydrology and using high-performance computing to create a holistic view of the future.

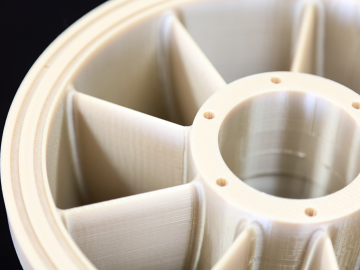

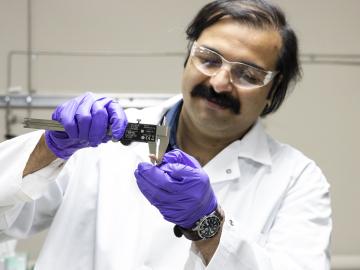

A new report published by ORNL assessed how advanced manufacturing and materials, such as 3D printing and novel component coatings, could offer solutions to modernize the existing fleet and design new approaches to hydropower.

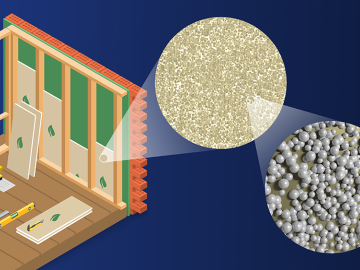

Scientists at ORNL developed a competitive, eco-friendly alternative made without harmful blowing agents.

The presence of minerals called ash in plants makes little difference to the fitness of new naturally derived compound materials designed for additive manufacturing, an Oak Ridge National Laboratory-led team found.

Researchers at Oak Ridge National Laboratory have identified a key need for future hydropower innovations – full-scale testing – to better inform developers and operators before making major investments.

Oak Ridge National Laboratory scientists designed a recyclable polymer for carbon-fiber composites to enable circular manufacturing of parts that boost energy efficiency in automotive, wind power and aerospace applications.

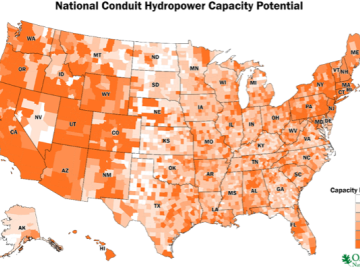

Millions of miles of pipelines and conduits across the United States make up an intricate network of waterways used for municipal, agricultural and industrial purposes.

ORNL has provided hydropower operators with new data to better prepare for extreme weather events and shifts in seasonal energy demands caused by climate change.

To further the potential benefits of the nation’s hydropower resources, researchers at Oak Ridge National Laboratory have developed and maintain a comprehensive water energy digital platform called HydroSource.

Chemical and environmental engineer Samarthya Bhagia is focused on achieving carbon neutrality and a circular economy by designing new plant-based materials for a range of applications from energy storage devices and sensors to environmentally friendly bioplastics.