Filter News

Area of Research

News Topics

- (-) Composites (28)

- (-) Hydropower (11)

- (-) Net Zero (14)

- 3-D Printing/Advanced Manufacturing (124)

- Advanced Reactors (34)

- Artificial Intelligence (94)

- Big Data (57)

- Bioenergy (92)

- Biology (100)

- Biomedical (59)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (66)

- Clean Water (30)

- Climate Change (101)

- Computer Science (192)

- Coronavirus (46)

- Critical Materials (27)

- Cybersecurity (35)

- Decarbonization (80)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (109)

- Environment (196)

- Exascale Computing (38)

- Fossil Energy (6)

- Frontier (43)

- Fusion (55)

- Grid (65)

- High-Performance Computing (87)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (48)

- Materials (144)

- Materials Science (141)

- Mathematics (9)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (65)

- Neutron Science (131)

- Nuclear Energy (109)

- Partnerships (46)

- Physics (62)

- Polymers (33)

- Quantum Computing (35)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (49)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (58)

- Sustainable Energy (129)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

ORNL has provided hydropower operators with new data to better prepare for extreme weather events and shifts in seasonal energy demands caused by climate change.

To further the potential benefits of the nation’s hydropower resources, researchers at Oak Ridge National Laboratory have developed and maintain a comprehensive water energy digital platform called HydroSource.

Chemical and environmental engineer Samarthya Bhagia is focused on achieving carbon neutrality and a circular economy by designing new plant-based materials for a range of applications from energy storage devices and sensors to environmentally friendly bioplastics.

Although more than 92,000 dams populate the country, the vast majority — about 89,000 — do not generate electricity through hydropower.

As the United States moves toward more sustainable and renewable sources of energy, hydropower is expected to play a pivotal role in integrating more intermittent renewables like wind and solar to the electricity grid

What’s getting Jim Szybist fired up these days? It’s the opportunity to apply his years of alternative fuel combustion and thermodynamics research to the challenge of cleaning up the hard-to-decarbonize, heavy-duty mobility sector — from airplanes to locomotives to ships and massive farm combines.

A new Department of Energy report produced by Oak Ridge National Laboratory identifies several supply chain must-haves in maintaining the pivotal role hydropower will play in decarbonizing the nation’s grid.

Researchers at Oak Ridge National Laboratory are using a novel approach in determining environmental impacts to aquatic species near hydropower facilities, potentially leading to smarter facility designs that can support electrical grid reliability.

Ten scientists from the Department of Energy’s Oak Ridge National Laboratory are among the world’s most highly cited researchers, according to a bibliometric analysis conducted by the scientific publication analytics firm Clarivate.

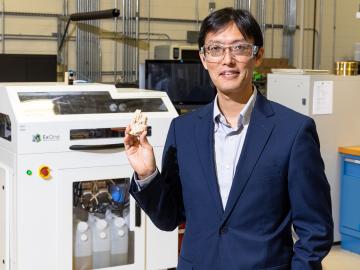

Researchers at ORNL designed a novel polymer to bind and strengthen silica sand for binder jet additive manufacturing, a 3D-printing method used by industries for prototyping and part production.