Filter News

Area of Research

- Advanced Manufacturing (5)

- Biology and Environment (43)

- Building Technologies (2)

- Clean Energy (105)

- Computational Biology (1)

- Computational Engineering (1)

- Computer Science (5)

- Electricity and Smart Grid (3)

- Energy Sciences (1)

- Functional Materials for Energy (1)

- Fusion and Fission (6)

- Fusion Energy (2)

- Isotopes (24)

- Materials (34)

- Materials for Computing (7)

- National Security (27)

- Neutron Science (9)

- Nuclear Science and Technology (7)

- Quantum information Science (3)

- Sensors and Controls (1)

- Supercomputing (61)

News Topics

- (-) Cybersecurity (35)

- (-) Grid (62)

- (-) Isotopes (53)

- (-) Summit (57)

- (-) Sustainable Energy (125)

- 3-D Printing/Advanced Manufacturing (121)

- Advanced Reactors (34)

- Artificial Intelligence (91)

- Big Data (53)

- Bioenergy (91)

- Biology (98)

- Biomedical (58)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (63)

- Clean Water (29)

- Climate Change (99)

- Composites (26)

- Computer Science (187)

- Coronavirus (46)

- Critical Materials (26)

- Decarbonization (79)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (108)

- Environment (194)

- Exascale Computing (37)

- Fossil Energy (5)

- Frontier (42)

- Fusion (54)

- High-Performance Computing (84)

- Hydropower (11)

- Irradiation (3)

- ITER (7)

- Machine Learning (47)

- Materials (144)

- Materials Science (140)

- Mathematics (7)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (61)

- Net Zero (13)

- Neutron Science (131)

- Nuclear Energy (108)

- Partnerships (44)

- Physics (61)

- Polymers (33)

- Quantum Computing (34)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (47)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

In a discovery aimed at accelerating the development of process-advantaged crops for jet biofuels, scientists at ORNL developed a capability to insert multiple genes into plants in a single step.

ORNL will team up with six of eight companies that are advancing designs and research and development for fusion power plants with the mission to achieve a pilot-scale demonstration of fusion within a decade.

ORNL’s electromagnetic isotope separator, or EMIS, made history in 2018 when it produced 500 milligrams of the rare isotope ruthenium-96, unavailable anywhere else in the world.

Oak Ridge National Laboratory scientists led the development of a supply chain model revealing the optimal places to site farms, biorefineries, pipelines and other infrastructure for sustainable aviation fuel production.

Inspired by one of the mysteries of human perception, an ORNL researcher invented a new way to hide sensitive electric grid information from cyberattack: within a constantly changing color palette.

Growing up in suburban Upper East Tennessee, Layla Marshall didn’t see a lot of STEM opportunities for children.

“I like encouraging young people to get involved in the kinds of things I’ve been doing in my career,” said Marshall. “I like seeing the students achieve their goals. It’s fun to watch them get excited about learning new things and teaching the robot to do things that they didn’t know it could do until they tried it.”

Marshall herself has a passion for learning new things.

A team of researchers from ORNL was recognized by the National Cancer Institute in March for their unique contributions in the fight against cancer.

Researchers at ORNL are helping modernize power management and enhance reliability in an increasingly complex electric grid.

A series of new classes at Pellissippi State Community College will offer students a new career path — and a national laboratory a pipeline of workers who have the skills needed for its own rapidly growing programs.

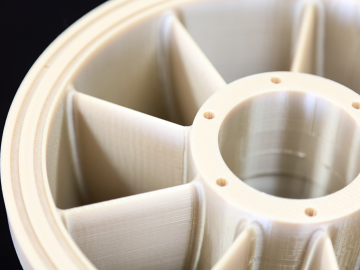

A new report published by ORNL assessed how advanced manufacturing and materials, such as 3D printing and novel component coatings, could offer solutions to modernize the existing fleet and design new approaches to hydropower.