Filter News

Area of Research

- Advanced Manufacturing (1)

- Biology and Environment (101)

- Biology and Soft Matter (1)

- Clean Energy (60)

- Climate and Environmental Systems (5)

- Computational Biology (1)

- Computational Engineering (2)

- Computer Science (2)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (1)

- Fusion and Fission (3)

- Fusion Energy (1)

- Isotopes (1)

- Materials (49)

- Materials for Computing (2)

- Mathematics (1)

- National Security (7)

- Neutron Science (22)

- Nuclear Science and Technology (6)

- Quantum information Science (1)

- Supercomputing (66)

News Topics

- (-) Environment (201)

- (-) Physics (64)

- (-) Summit (61)

- (-) Transformational Challenge Reactor (7)

- 3-D Printing/Advanced Manufacturing (128)

- Advanced Reactors (35)

- Artificial Intelligence (102)

- Big Data (62)

- Bioenergy (92)

- Biology (102)

- Biomedical (62)

- Biotechnology (24)

- Buildings (67)

- Chemical Sciences (74)

- Clean Water (31)

- Climate Change (106)

- Composites (30)

- Computer Science (199)

- Coronavirus (46)

- Critical Materials (29)

- Cybersecurity (35)

- Decarbonization (85)

- Education (5)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (112)

- Exascale Computing (44)

- Fossil Energy (6)

- Frontier (46)

- Fusion (59)

- Grid (67)

- High-Performance Computing (94)

- Hydropower (11)

- Irradiation (3)

- Isotopes (57)

- ITER (7)

- Machine Learning (51)

- Materials (150)

- Materials Science (149)

- Mathematics (10)

- Mercury (12)

- Microelectronics (4)

- Microscopy (51)

- Molten Salt (9)

- Nanotechnology (60)

- National Security (73)

- Net Zero (14)

- Neutron Science (140)

- Nuclear Energy (111)

- Partnerships (51)

- Polymers (33)

- Quantum Computing (39)

- Quantum Science (73)

- Renewable Energy (2)

- Security (26)

- Simulation (53)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Sustainable Energy (130)

- Transportation (99)

Media Contacts

Four research teams from the Department of Energy’s Oak Ridge National Laboratory and their technologies have received 2020 R&D 100 Awards.

Rufus Ritchie came from Kentucky coal country, a region not known for producing physicists.

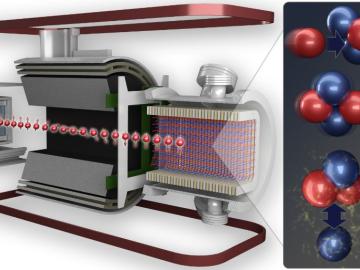

Through a one-of-a-kind experiment at ORNL, nuclear physicists have precisely measured the weak interaction between protons and neutrons. The result quantifies the weak force theory as predicted by the Standard Model of Particle Physics.

About 60 years ago, scientists discovered that a certain rare earth metal-hydrogen mixture, yttrium, could be the ideal moderator to go inside small, gas-cooled nuclear reactors.

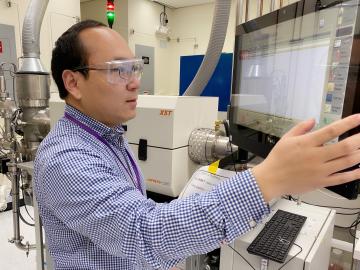

Systems biologist Paul Abraham uses his fascination with proteins, the molecular machines of nature, to explore new ways to engineer more productive ecosystems and hardier bioenergy crops.

It’s a new type of nuclear reactor core. And the materials that will make it up are novel — products of Oak Ridge National Laboratory’s advanced materials and manufacturing technologies.

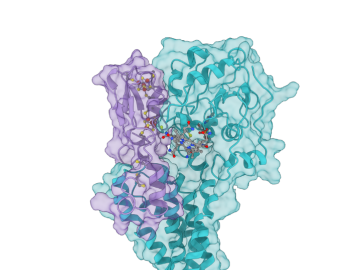

A team led by ORNL created a computational model of the proteins responsible for the transformation of mercury to toxic methylmercury, marking a step forward in understanding how the reaction occurs and how mercury cycles through the environment.

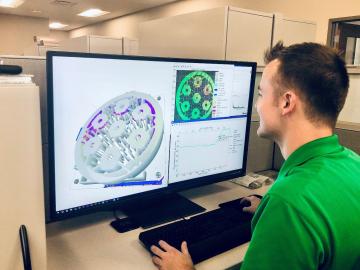

Oak Ridge National Laboratory researchers have developed artificial intelligence software for powder bed 3D printers that assesses the quality of parts in real time, without the need for expensive characterization equipment.