Filter News

Area of Research

News Topics

- (-) Fusion (55)

- (-) Mercury (12)

- (-) Molten Salt (8)

- (-) Polymers (33)

- 3-D Printing/Advanced Manufacturing (125)

- Advanced Reactors (34)

- Artificial Intelligence (94)

- Big Data (58)

- Bioenergy (92)

- Biology (100)

- Biomedical (59)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (66)

- Clean Water (30)

- Climate Change (101)

- Composites (28)

- Computer Science (193)

- Coronavirus (46)

- Critical Materials (28)

- Cybersecurity (35)

- Decarbonization (80)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (109)

- Environment (196)

- Exascale Computing (39)

- Fossil Energy (6)

- Frontier (44)

- Grid (65)

- High-Performance Computing (88)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (48)

- Materials (144)

- Materials Science (142)

- Mathematics (9)

- Microelectronics (3)

- Microscopy (51)

- Nanotechnology (60)

- National Security (65)

- Net Zero (14)

- Neutron Science (131)

- Nuclear Energy (109)

- Partnerships (46)

- Physics (62)

- Quantum Computing (35)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (49)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (59)

- Sustainable Energy (129)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

Kathy McCarthy has been named director of the US ITER Project Office at the Department of Energy’s Oak Ridge National Laboratory, effective March 2020.

The U.S. Department of Energy announced funding for 12 projects with private industry to enable collaboration with DOE national laboratories on overcoming challenges in fusion energy development.

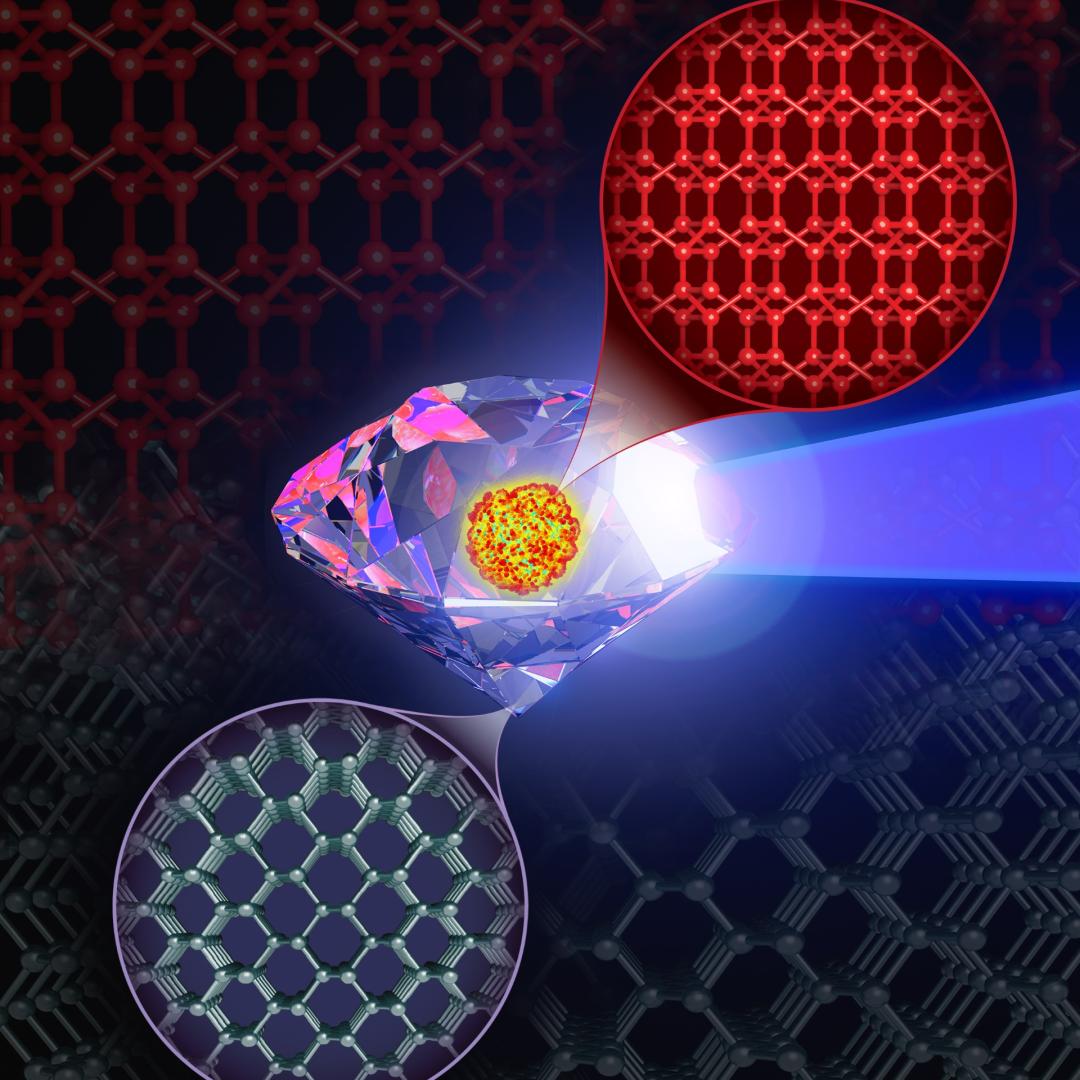

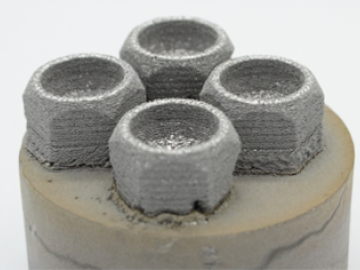

Using additive manufacturing, scientists experimenting with tungsten at Oak Ridge National Laboratory hope to unlock new potential of the high-performance heat-transferring material used to protect components from the plasma inside a fusion reactor. Fusion requires hydrogen isotopes to reach millions of degrees.

A team of researchers at Oak Ridge National Laboratory have demonstrated that designed synthetic polymers can serve as a high-performance binding material for next-generation lithium-ion batteries.

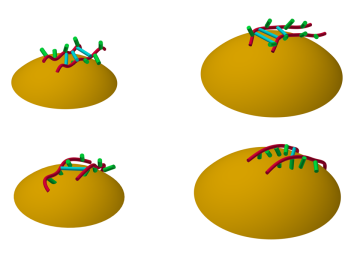

Sometimes solutions to the biggest problems can be found in the smallest details. The work of biochemist Alex Johs at Oak Ridge National Laboratory bears this out, as he focuses on understanding protein structures and molecular interactions to resolve complex global problems like the spread of mercury pollution in waterways and the food supply.

Vera Bocharova at the Department of Energy’s Oak Ridge National Laboratory investigates the structure and dynamics of soft materials—polymer nanocomposites, polymer electrolytes and biological macromolecules—to advance materials and technologies for energy, medicine and other applications.

Scientists have tested a novel heat-shielding graphite foam, originally created at Oak Ridge National Laboratory, at Germany’s Wendelstein 7-X stellarator with promising results for use in plasma-facing components of fusion reactors.

Oak Ridge National Laboratory scientists analyzed more than 50 years of data showing puzzlingly inconsistent trends about corrosion of structural alloys in molten salts and found one factor mattered most—salt purity.

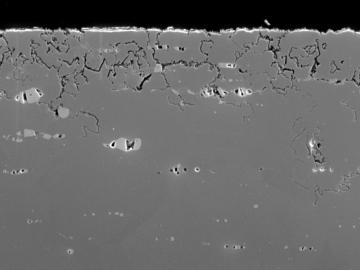

Scientists from Oak Ridge National Laboratory performed a corrosion test in a neutron radiation field to support the continued development of molten salt reactors.

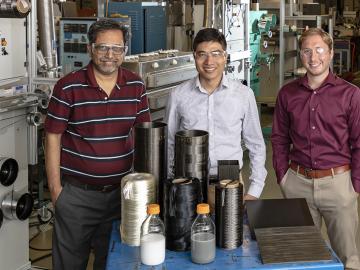

Carbon fiber composites—lightweight and strong—are great structural materials for automobiles, aircraft and other transportation vehicles. They consist of a polymer matrix, such as epoxy, into which reinforcing carbon fibers have been embedded. Because of differences in the mecha...