Filter News

Area of Research

News Topics

- (-) Critical Materials (28)

- (-) Exascale Computing (39)

- (-) Mercury (12)

- (-) Molten Salt (8)

- 3-D Printing/Advanced Manufacturing (125)

- Advanced Reactors (34)

- Artificial Intelligence (95)

- Big Data (58)

- Bioenergy (92)

- Biology (100)

- Biomedical (59)

- Biotechnology (23)

- Buildings (59)

- Chemical Sciences (68)

- Clean Water (30)

- Climate Change (101)

- Composites (29)

- Computer Science (194)

- Coronavirus (46)

- Cybersecurity (35)

- Decarbonization (81)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (110)

- Environment (197)

- Fossil Energy (6)

- Frontier (44)

- Fusion (55)

- Grid (65)

- High-Performance Computing (88)

- Hydropower (11)

- Irradiation (3)

- Isotopes (54)

- ITER (7)

- Machine Learning (48)

- Materials (144)

- Materials Science (143)

- Mathematics (9)

- Microelectronics (3)

- Microscopy (51)

- Nanotechnology (60)

- National Security (67)

- Net Zero (14)

- Neutron Science (132)

- Nuclear Energy (110)

- Partnerships (49)

- Physics (63)

- Polymers (33)

- Quantum Computing (35)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (49)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (59)

- Sustainable Energy (129)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

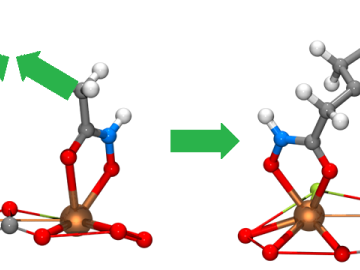

Scientists from the Critical Materials Institute used the Titan supercomputer and Eos computing cluster at ORNL to analyze designer molecules that could increase the yield of rare earth elements found in bastnaesite, an important mineral

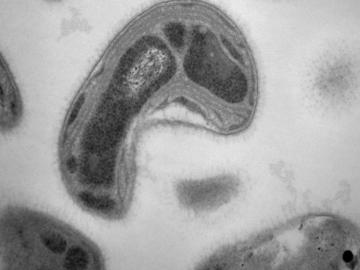

Biologists from Oak Ridge National Laboratory and the Smithsonian Environmental Research Center have confirmed that microorganisms called methanogens can transform mercury into the neurotoxin methylmercury with varying efficiency across species.

Experts focused on the future of nuclear technology will gather at Oak Ridge National Laboratory for the fourth annual Molten Salt Reactor Workshop on October 3–4.

Oak Ridge National Laboratory has developed a salt purification lab to study the viability of using liquid salt that contains lithium fluoride and beryllium fluoride, known as FLiBe, to cool molten salt reactors, or MSRs. Multiple American companies developing advanced reactor technol...

Thanks in large part to developing and operating a facility for testing molten salt reactor (MSR) technologies, nuclear experts at the Energy Department’s Oak Ridge National Laboratory (ORNL) are now tackling the next generation of another type of clean energy—concentrating ...

A team led by the Department of Energy’s Oak Ridge National Laboratory has identified a novel microbial process that can break down toxic methylmercury in the environment, a fundamental scientific discovery that could potentially reduce mercury toxicity levels and sup...

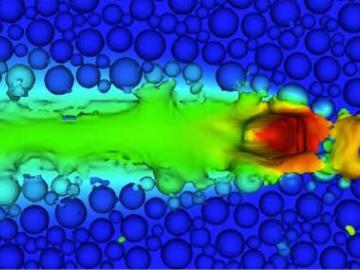

Oak Ridge National Laboratory experts are playing leading roles in the recently established Department of Energy’s (DOE’s) Exascale Computing Project (ECP), a multi-lab initiative responsible for developing the strategy, aligning the resources, and conducting the R&D necessary to achieve the nation’s imperative of delivering exascale computing by 2021.

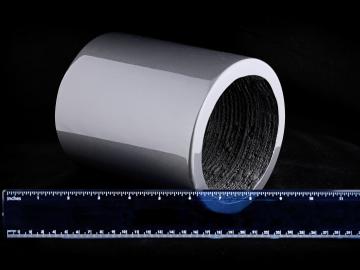

Researchers at the Department of Energy’s Oak Ridge National Laboratory have demonstrated that permanent magnets produced by additive manufacturing can outperform bonded magnets made using traditional techniques while conserving critical materials. Scientists fabric...

The Department of Energy’s Oak Ridge National Laboratory has received funding from DOE’s Exascale Computing Project (ECP) to develop applications for future exascale systems that will be 50 to 100 times more powerful than today’s fastest supercomputers.

A process developed at Oak Ridge National Laboratory for large-scale recovery of rare earth magnets from used computer hard drives will undergo industrial testing under a new agreement between Oddello Industries LLC and ORNL, as part of the Department of Energy’s Crit...