Filter News

Area of Research

- Advanced Manufacturing (1)

- Biology and Environment (15)

- Clean Energy (14)

- Climate and Environmental Systems (1)

- Energy Frontier Research Centers (1)

- Fusion and Fission (1)

- Materials (42)

- Materials for Computing (7)

- National Security (1)

- Neutron Science (10)

- Nuclear Science and Technology (3)

- Quantum information Science (1)

- Supercomputing (11)

News Topics

- (-) Mercury (12)

- (-) Nanotechnology (60)

- (-) Transformational Challenge Reactor (7)

- 3-D Printing/Advanced Manufacturing (120)

- Advanced Reactors (34)

- Artificial Intelligence (91)

- Big Data (53)

- Bioenergy (91)

- Biology (98)

- Biomedical (58)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (63)

- Clean Water (29)

- Climate Change (99)

- Composites (26)

- Computer Science (187)

- Coronavirus (46)

- Critical Materials (25)

- Cybersecurity (35)

- Decarbonization (79)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (108)

- Environment (194)

- Exascale Computing (37)

- Fossil Energy (5)

- Frontier (42)

- Fusion (54)

- Grid (62)

- High-Performance Computing (84)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (47)

- Materials (143)

- Materials Science (139)

- Mathematics (7)

- Microelectronics (3)

- Microscopy (51)

- Molten Salt (8)

- National Security (61)

- Net Zero (13)

- Neutron Science (131)

- Nuclear Energy (107)

- Partnerships (43)

- Physics (61)

- Polymers (33)

- Quantum Computing (34)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (47)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Sustainable Energy (125)

- Transportation (97)

Media Contacts

New capabilities and equipment recently installed at the Department of Energy’s Oak Ridge National Laboratory are bringing a creek right into the lab to advance understanding of mercury pollution and accelerate solutions.

Two scientists with the Department of Energy’s Oak Ridge National Laboratory have been elected fellows of the American Physical Society.

Scientists at Oak Ridge National Laboratory and the University of Tennessee designed and demonstrated a method to make carbon-based materials that can be used as electrodes compatible with a specific semiconductor circuitry.

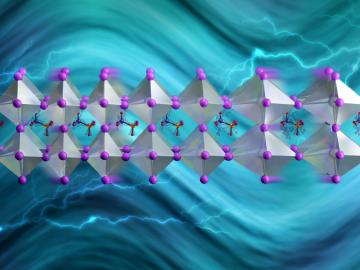

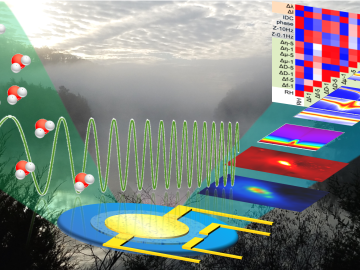

Led by ORNL and the University of Tennessee, Knoxville, a study of a solar-energy material with a bright future revealed a way to slow phonons, the waves that transport heat.

About 60 years ago, scientists discovered that a certain rare earth metal-hydrogen mixture, yttrium, could be the ideal moderator to go inside small, gas-cooled nuclear reactors.

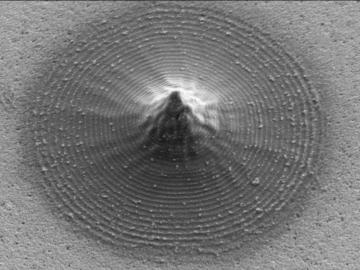

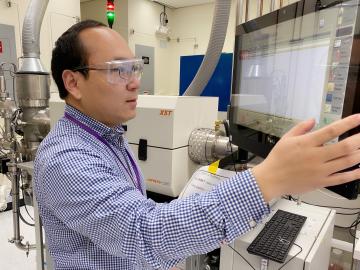

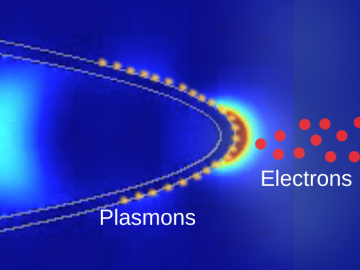

Scientists at ORNL and the University of Nebraska have developed an easier way to generate electrons for nanoscale imaging and sensing, providing a useful new tool for material science, bioimaging and fundamental quantum research.

It’s a new type of nuclear reactor core. And the materials that will make it up are novel — products of Oak Ridge National Laboratory’s advanced materials and manufacturing technologies.

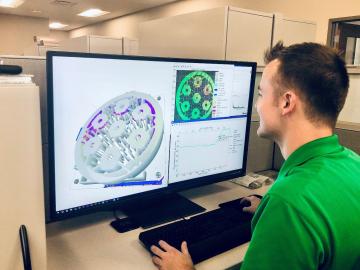

Oak Ridge National Laboratory researchers have developed artificial intelligence software for powder bed 3D printers that assesses the quality of parts in real time, without the need for expensive characterization equipment.

An all-in-one experimental platform developed at Oak Ridge National Laboratory’s Center for Nanophase Materials Sciences accelerates research on promising materials for future technologies.

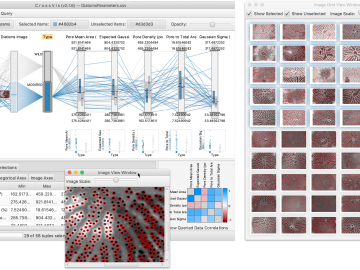

From materials science and earth system modeling to quantum information science and cybersecurity, experts in many fields run simulations and conduct experiments to collect the abundance of data necessary for scientific progress.