Filter News

Area of Research

News Topics

- (-) Critical Materials (29)

- (-) Microscopy (56)

- 3-D Printing/Advanced Manufacturing (142)

- Advanced Reactors (40)

- Artificial Intelligence (124)

- Big Data (77)

- Bioenergy (107)

- Biology (123)

- Biomedical (72)

- Biotechnology (35)

- Buildings (73)

- Chemical Sciences (84)

- Clean Water (32)

- Composites (33)

- Computer Science (223)

- Coronavirus (48)

- Cybersecurity (35)

- Education (5)

- Element Discovery (1)

- Emergency (4)

- Energy Storage (114)

- Environment (217)

- Exascale Computing (64)

- Fossil Energy (8)

- Frontier (62)

- Fusion (65)

- Grid (73)

- High-Performance Computing (128)

- Hydropower (12)

- Irradiation (3)

- Isotopes (62)

- ITER (9)

- Machine Learning (66)

- Materials (156)

- Materials Science (155)

- Mathematics (12)

- Mercury (12)

- Microelectronics (4)

- Molten Salt (10)

- Nanotechnology (62)

- National Security (85)

- Neutron Science (169)

- Nuclear Energy (121)

- Partnerships (66)

- Physics (68)

- Polymers (34)

- Quantum Computing (51)

- Quantum Science (87)

- Security (30)

- Simulation (64)

- Software (1)

- Space Exploration (26)

- Statistics (4)

- Summit (70)

- Transportation (102)

Media Contacts

Robert “Bob” Hettich, an ORNL Corporate Fellow, is a pioneer in using mass spectrometry to uncover how microbes interact within complex environments and influence larger systems like plants and humans. A founder of the field of metaproteomics, he leads research that supports bioenergy, environmental resilience and health through advanced protein analysis.

Neus Domingo Marimon, leader of the Functional Atomic Force Microscopy group at the Center for Nanophase Materials Sciences of ORNL, has been elevated to senior member of the Institute of Electrical and Electronics Engineers.

P&G is using simulations on the ORNL Summit supercomputer to study how surfactants in cleaners cause eye irritation. By modeling the corneal epithelium, P&G aims to develop safer, concentrated cleaning products that meet performance and safety standards while supporting sustainability goals.

Chad Parish, a senior researcher at ORNL, studies materials at the atomic level to improve nuclear reactors. His work focuses on fusion and fission energy, using microscopy and collaborating with experts to advance materials for extreme environments.

The US focuses on nuclear nonproliferation, and ORNL plays a key role in this mission. The lab conducts advanced research in uranium science, materials analysis and nuclear forensics to detect illicit nuclear activities. Using cutting-edge tools and operational systems, ORNL supports global efforts to reduce nuclear threats by uncovering the history of nuclear materials and providing solutions for uranium removal.

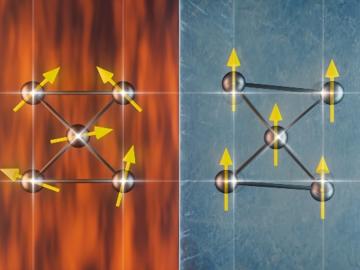

At ORNL, a group of scientists used neutron scattering techniques to investigate a relatively new functional material called a Weyl semimetal. These Weyl fermions move very quickly in a material and can carry electrical charge at room temperature. Scientists think that Weyl semimetals, if used in future electronics, could allow electricity to flow more efficiently and enable more energy-efficient computers and other electronic devices.

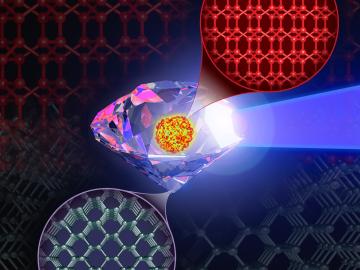

The world’s fastest supercomputer helped researchers simulate synthesizing a material harder and tougher than a diamond — or any other substance on Earth. The study used Frontier to predict the likeliest strategy to synthesize such a material, thought to exist so far only within the interiors of giant exoplanets, or planets beyond our solar system.

Brian Sanders is focused on impactful, multidisciplinary science at Oak Ridge National Laboratory, developing solutions for everything from improved imaging of plant-microbe interactions that influence ecosystem health to advancing new treatments for cancer and viral infections.

Advanced materials research to enable energy-efficient, cost-competitive and environmentally friendly technologies for the United States and Japan is the goal of a memorandum of understanding, or MOU, between the Department of Energy’s Oak Ridge National Laboratory and Japan’s National Institute of Materials Science.

ORNL researchers used electron-beam additive manufacturing to 3D-print the first complex, defect-free tungsten parts with complex geometries.