Filter News

Area of Research

News Topics

- (-) Critical Materials (29)

- (-) Irradiation (3)

- (-) Molten Salt (8)

- (-) Transformational Challenge Reactor (7)

- 3-D Printing/Advanced Manufacturing (125)

- Advanced Reactors (34)

- Artificial Intelligence (97)

- Big Data (60)

- Bioenergy (92)

- Biology (100)

- Biomedical (60)

- Biotechnology (23)

- Buildings (61)

- Chemical Sciences (70)

- Clean Water (31)

- Climate Change (104)

- Composites (29)

- Computer Science (195)

- Coronavirus (46)

- Cybersecurity (35)

- Decarbonization (82)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (112)

- Environment (198)

- Exascale Computing (40)

- Fossil Energy (6)

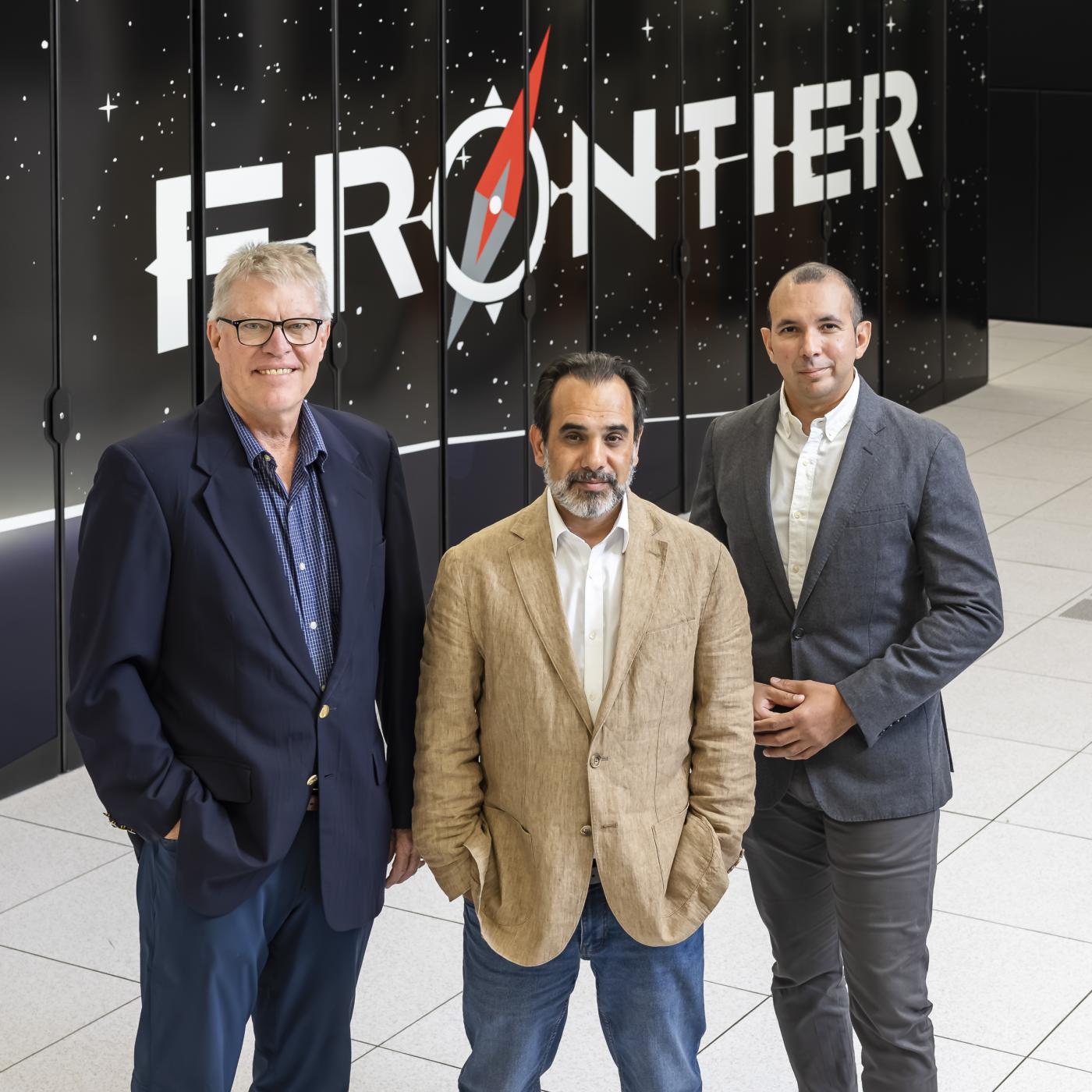

- Frontier (44)

- Fusion (57)

- Grid (66)

- High-Performance Computing (90)

- Hydropower (11)

- Isotopes (55)

- ITER (7)

- Machine Learning (49)

- Materials (145)

- Materials Science (145)

- Mathematics (9)

- Mercury (12)

- Microelectronics (4)

- Microscopy (51)

- Nanotechnology (60)

- National Security (71)

- Net Zero (14)

- Neutron Science (134)

- Nuclear Energy (110)

- Partnerships (49)

- Physics (63)

- Polymers (33)

- Quantum Computing (37)

- Quantum Science (71)

- Renewable Energy (2)

- Security (25)

- Simulation (49)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (59)

- Sustainable Energy (130)

- Transportation (97)

Media Contacts

ORNL, TVA and TNECD were recognized by the Federal Laboratory Consortium for their impactful partnership that resulted in a record $2.3 billion investment by Ultium Cells, a General Motors and LG Energy Solution joint venture, to build a battery cell manufacturing plant in Spring Hill, Tennessee.

A novel method to 3D print components for nuclear reactors, developed by the Department of Energy’s Oak Ridge National Laboratory, has been licensed by Ultra Safe Nuclear Corporation.

To advance sensor technologies, Oak Ridge National Laboratory researchers studied piezoelectric materials, which convert mechanical stress into electrical energy, to see how they could handle bombardment with energetic neutrons.

A new technology for rare-earth elements chemical separation has been licensed to Marshallton Research Laboratories, a North Carolina-based manufacturer of organic chemicals for a range of industries.

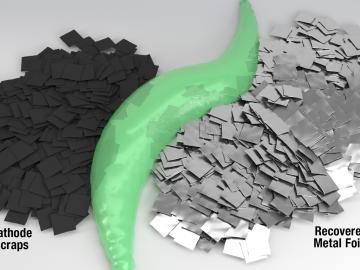

Researchers at ORNL have developed a robotic disassembly system for spent electric vehicle battery packs to safely and efficiently recycle and reuse critical materials while reducing toxic waste.

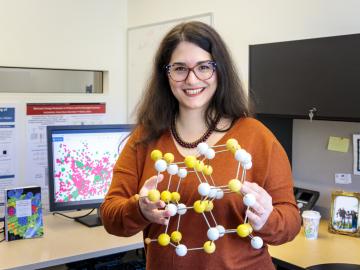

Scientists at Oak Ridge National Laboratory have developed a solvent that results in a more environmentally friendly process to recover valuable materials from used lithium-ion batteries, supports a stable domestic supply chain for new batteries

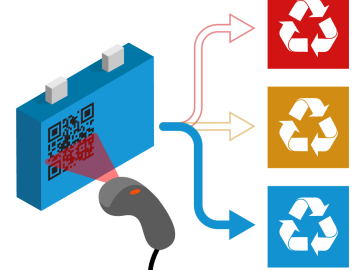

Scientists at Oak Ridge National Laboratory have devised a method to identify the unique chemical makeup of every lithium-ion battery around the world, information that could accelerate recycling, recover critical materials and resolve a growing waste stream.

Six scientists at the Department of Energy’s Oak Ridge National Laboratory were named Battelle Distinguished Inventors, in recognition of obtaining 14 or more patents during their careers at the lab.

Momentum Technologies Inc., a Dallas, Texas-based materials science company that is focused on extracting critical metals from electronic waste, has licensed an Oak Ridge National Laboratory process for recovering cobalt and other metals from spent

About 60 years ago, scientists discovered that a certain rare earth metal-hydrogen mixture, yttrium, could be the ideal moderator to go inside small, gas-cooled nuclear reactors.