Filter News

Area of Research

- Advanced Manufacturing (6)

- Biology and Environment (15)

- Clean Energy (101)

- Electricity and Smart Grid (1)

- Fuel Cycle Science and Technology (1)

- Functional Materials for Energy (2)

- Fusion and Fission (3)

- Fusion Energy (1)

- Isotopes (5)

- Materials (86)

- Materials Characterization (2)

- Materials for Computing (15)

- Materials Under Extremes (1)

- National Security (36)

- Neutron Science (21)

- Supercomputing (27)

- Transportation Systems (2)

News Topics

- (-) Materials (144)

- (-) National Security (61)

- (-) Transportation (97)

- 3-D Printing/Advanced Manufacturing (121)

- Advanced Reactors (34)

- Artificial Intelligence (91)

- Big Data (53)

- Bioenergy (92)

- Biology (99)

- Biomedical (58)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (65)

- Clean Water (29)

- Climate Change (99)

- Composites (26)

- Computer Science (188)

- Coronavirus (46)

- Critical Materials (26)

- Cybersecurity (35)

- Decarbonization (80)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (109)

- Environment (194)

- Exascale Computing (37)

- Fossil Energy (6)

- Frontier (42)

- Fusion (54)

- Grid (62)

- High-Performance Computing (84)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (48)

- Materials Science (141)

- Mathematics (8)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- Net Zero (14)

- Neutron Science (131)

- Nuclear Energy (108)

- Partnerships (44)

- Physics (61)

- Polymers (33)

- Quantum Computing (34)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (47)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (57)

- Sustainable Energy (126)

- Transformational Challenge Reactor (7)

Media Contacts

A team of researchers at Oak Ridge National Laboratory and the University of Tennessee have developed a concrete mix that demonstrated high early strength within six hours of mixing, potentially doubling the production capacity for the precast industry.

Scientists at Oak Ridge National Laboratory successfully demonstrated a technique to heal dendrites that formed in a solid electrolyte, resolving an issue that can hamper the performance of high energy-density, solid-state batteries.

Xin Sun has been selected as the associate laboratory director for the Energy Science and Technology Directorate, or ESTD, at the Department of Energy’s Oak Ridge National Laboratory.

A team of Oak Ridge National Laboratory researchers demonstrated that an additively manufactured hot stamping die – a tool used to create car body components – cooled faster than those produced by conventional manufacturing methods.

For a researcher who started out in mechanical engineering with a focus on engine combustion, Martin Wissink has learned a lot about neutrons on the job

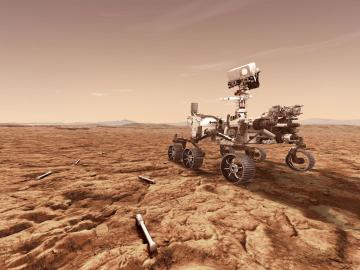

On Feb. 18, the world will be watching as NASA’s Perseverance rover makes its final descent into Jezero Crater on the surface of Mars. Mars 2020 is the first NASA mission that uses plutonium-238 produced at the Department of Energy’s Oak Ridge National Laboratory.

Thirty-two Oak Ridge National Laboratory employees were named among teams recognized by former DOE Secretary Dan Brouillette with Secretary’s Honor Awards as he completed his term. Four teams received new awards that reflect DOE responses to the coronavirus pandemic.

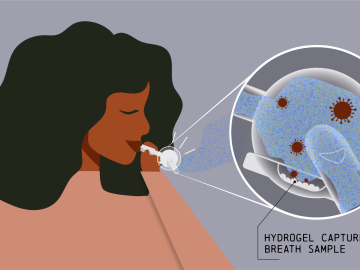

Collaborators at Oak Ridge National Laboratory and the University of Tennessee Health Science Center are developing a breath-sampling whistle that could make COVID-19 screening easy to do at home.

The ExOne Company, the global leader in industrial sand and metal 3D printers using binder jetting technology, announced it has reached a commercial license agreement with Oak Ridge National Laboratory to 3D print parts in aluminum-infiltrated boron carbide.