Filter News

Area of Research

- Advanced Manufacturing (3)

- Biology and Environment (1)

- Clean Energy (9)

- Fuel Cycle Science and Technology (1)

- Fusion and Fission (27)

- Fusion Energy (10)

- Isotope Development and Production (1)

- Isotopes (6)

- Materials (17)

- Materials for Computing (1)

- National Security (5)

- Neutron Science (6)

- Nuclear Science and Technology (36)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Supercomputing (7)

News Topics

- (-) Nuclear Energy (107)

- (-) Space Exploration (25)

- 3-D Printing/Advanced Manufacturing (119)

- Advanced Reactors (34)

- Artificial Intelligence (91)

- Big Data (53)

- Bioenergy (91)

- Biology (98)

- Biomedical (58)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (63)

- Clean Water (29)

- Climate Change (99)

- Composites (26)

- Computer Science (187)

- Coronavirus (46)

- Critical Materials (25)

- Cybersecurity (35)

- Decarbonization (79)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (108)

- Environment (194)

- Exascale Computing (37)

- Fossil Energy (5)

- Frontier (42)

- Fusion (54)

- Grid (62)

- High-Performance Computing (84)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (47)

- Materials (143)

- Materials Science (139)

- Mathematics (7)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (61)

- Net Zero (13)

- Neutron Science (131)

- Partnerships (43)

- Physics (61)

- Polymers (33)

- Quantum Computing (34)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (47)

- Software (1)

- Statistics (3)

- Summit (57)

- Sustainable Energy (125)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

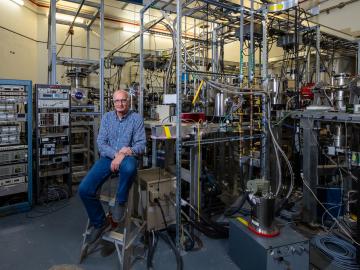

Scientists are using Oak Ridge National Laboratory’s Multicharged Ion Research Facility to simulate the cosmic origin of X-ray emissions resulting when highly charged ions collide with neutral atoms and molecules, such as helium and gaseous hydrogen.

Oak Ridge National Laboratory is debuting a small satellite ground station that uses high-performance computing to support automated detection of changes to Earth’s landscape.

To study how space radiation affects materials for spacecraft and satellites, Oak Ridge National Laboratory scientists sent samples to the International Space Station. The results will inform design of radiation-resistant magnetic and electronic systems.

ORNL and the Tennessee Valley Authority, or TVA, are joining forces to advance decarbonization technologies from discovery through deployment through a new memorandum of understanding, or MOU.

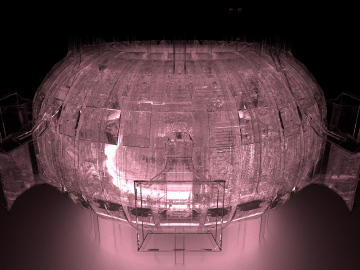

A new fusion record was announced February 9 in the United Kingdom: At the Joint European Torus, or JET, the team documented the generation of 59 megajoules of sustained fusion energy, more than doubling the

ORNL, TVA and TNECD were recognized by the Federal Laboratory Consortium for their impactful partnership that resulted in a record $2.3 billion investment by Ultium Cells, a General Motors and LG Energy Solution joint venture, to build a battery cell manufacturing plant in Spring Hill, Tennessee.

More than 50 current employees and recent retirees from ORNL received Department of Energy Secretary’s Honor Awards from Secretary Jennifer Granholm in January as part of project teams spanning the national laboratory system. The annual awards recognized 21 teams and three individuals for service and contributions to DOE’s mission and to the benefit of the nation.

A novel method to 3D print components for nuclear reactors, developed by the Department of Energy’s Oak Ridge National Laboratory, has been licensed by Ultra Safe Nuclear Corporation.

Four first-of-a-kind 3D-printed fuel assembly brackets, produced at the Department of Energy’s Manufacturing Demonstration Facility at Oak Ridge National Laboratory, have been installed and are now under routine operating

A research team at Oak Ridge National Laboratory have 3D printed a thermal protection shield, or TPS, for a capsule that will launch with the Cygnus cargo spacecraft as part of the supply mission to the International Space Station.