Efficiency from feedstock to finished part

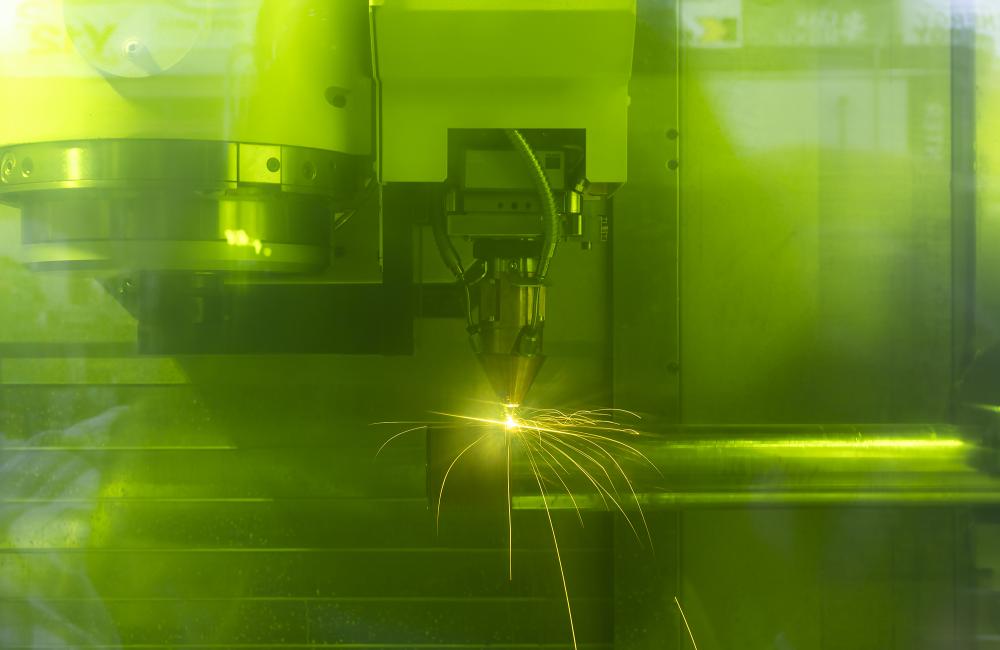

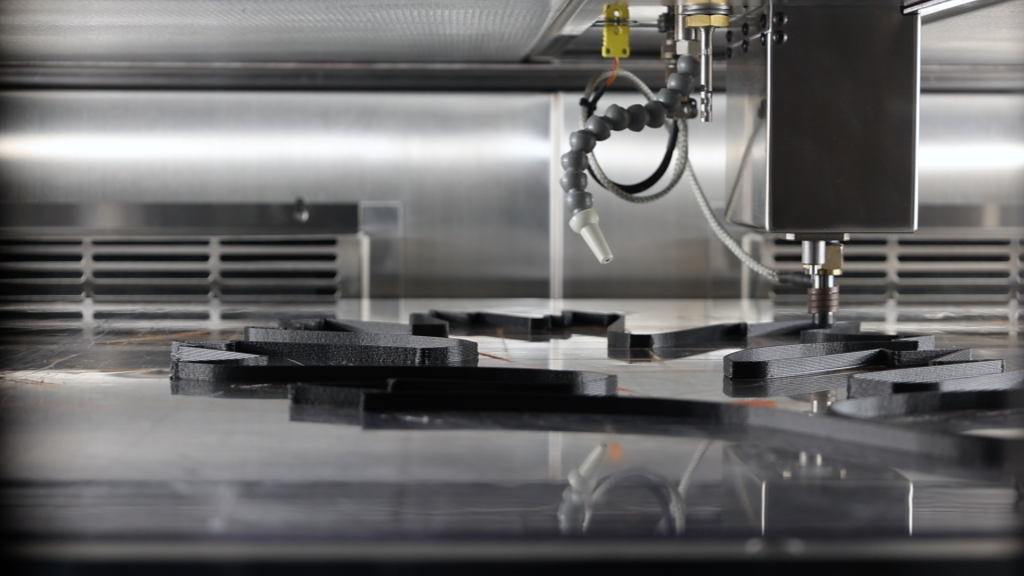

Convergent manufacturing is an emerging field where many advanced manufacturing technologies are integrated into a unified platform to streamline operations, significantly reduce production times, improve overall productivity and agility, enable precise geometric accuracy, and eliminate scrap through seamless repair and remanufacturing.

Discover the Future Foundries Platform

MDF has developed a new research platform for convergent manufacturing that integrates multiple systems into one, including a pallet changer, machining center, wire-arc additive manufacturing, heat treatment, inspection, and injection molding. A digital manufacturing thread interconnects each system for rapid, agile production. The platform debuted at the 2024 International Manufacturing Technology Show in Chicago, Illinois.

Advanced Systems Integration

The field is broadly focused on multi-feed processes and finishing for metals and composites. It has implications for many sectors including clean energy, national security, tooling, and transportation where there is a growing need to rapidly and cost effectively manufacture components with minimal modifications and enable scale-up or scale-down of supply chains based on changing demand conditions.

Enhancing Manufacturing Intelligence

MDF developed Slicer, a software platform that integrates computer-aided design, engineering, and manufacturing (CAD, CAE, and CAM) along with in-situ data. This ever-evolving platform enhances manufacturing intelligence across the entire workflow, reducing overall CAM time and minimizing manual interventions. By leveraging data science and machine learning, the platform facilitates more efficient and accurate manufacturing processes.

Holistic Design and Knowledge Transfer

The complexity of convergent manufacturing requires operators to have a deep understanding of integrated processes. MDF's approach includes the development of robust training programs, human-AI knowledge assistants, and advanced data analytic tools to ensure effective knowledge transfer and democratization of these advanced manufacturing techniques. This approach ensures operators are well-equipped to leverage the full potential of convergent manufacturing systems.

Optimized Performance and Sustainability

Emerging near-net preforming techniques, combined with advanced finishing processes, are enabling the production of large, finished components with enhanced performance and reduced environmental impact. MDF's collaborations with equipment manufacturers, software providers, and end users aims to innovate and democratize these technologies, contributing to significant reductions in CO2 emissions and overall manufacturing costs.

Recent Impacts

Working with the Tennessee Valley Authority, Mazak, and Open Mind, a team at MDF has found a cleaner way to efficiently and economically repair broken components used in power plants for energy generation.

Collaborating with Okuma and Open Mind, a team at MDF has created a streamlined workflow to manufacture multi-material pressure relief valves within a single system, eliminating the need for a multi-system process and manual welding.