Filter News

Area of Research

News Type

Media Contacts

A 20-kilowatt wireless charging system demonstrated at the Department of Energy’s Oak Ridge National Laboratory has achieved 90 percent efficiency at three times the rate of the plug-in systems commonly used for electric vehicles today. This ability can help acc...

Researchers at the Department of Energy’s Oak Ridge National Laboratory have demonstrated a production method they estimate will reduce the cost of carbon fiber as much as 50 percent and the energy used in its production by more than 60 percent. After extensive ...

Experts at the U.S. Department of Energy’s Oak Ridge National Laboratory will help nine small companies move their innovative manufacturing, buildings, fuel cell, geothermal and vehicle technologies closer to the marketplace. The businesses are among 33 selected t...

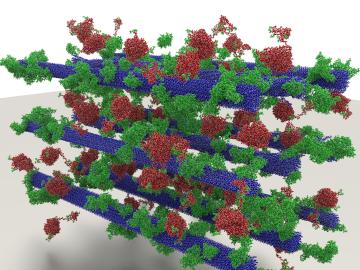

Three U.S. Department of Energy-funded research centers – the BioEnergy Science Center (Oak Ridge National Laboratory), the Great Lakes Bioenergy Research Center (University of Wisconsin–Madison and Michigan State University), and the Joint BioEnergy Institute (Lawrence Berkeley National Laboratory) – are making progress on a shared mission to develop technologies that will bring advanced biofuels to the marketplace, reporting today the disclosure of their 500th invention.

Fuel economy data, sticker price, emissions information, safety ratings and much more is available at your fingertips with the latest Find-a-Car tool, an app designed specifically for easy searches on mobile devices. FuelEconomy.gov, maintained by the Department of Energy with d...

People in cold climates who heat with electricity could realize savings of up to 70 percent with a new heat pump developed by Oak Ridge National Laboratory and Emerson Climate Technologies. The tandem compressor system, developed through a cooperative research and development ag...