Filter News

Area of Research

- (-) Clean Energy (62)

- (-) Nuclear Science and Technology (6)

- Advanced Manufacturing (10)

- Biology and Environment (16)

- Climate and Environmental Systems (4)

- Computer Science (2)

- Fusion and Fission (1)

- Fusion Energy (1)

- Materials (24)

- Materials for Computing (2)

- National Security (3)

- Neutron Science (17)

- Quantum information Science (6)

- Supercomputing (29)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (32)

- (-) Climate Change (6)

- (-) Coronavirus (8)

- (-) Environment (29)

- (-) Quantum Science (2)

- Advanced Reactors (11)

- Artificial Intelligence (5)

- Big Data (2)

- Bioenergy (16)

- Biology (1)

- Biomedical (4)

- Biotechnology (2)

- Chemical Sciences (2)

- Clean Water (5)

- Composites (3)

- Computer Science (17)

- Cybersecurity (3)

- Decarbonization (1)

- Energy Storage (20)

- Exascale Computing (1)

- Fusion (7)

- Grid (8)

- High-Performance Computing (1)

- Isotopes (4)

- Machine Learning (5)

- Materials (2)

- Materials Science (14)

- Mathematics (1)

- Mercury (1)

- Microscopy (4)

- Molten Salt (2)

- Nanotechnology (6)

- Neutron Science (8)

- Nuclear Energy (28)

- Physics (2)

- Polymers (4)

- Security (1)

- Space Exploration (4)

- Summit (2)

- Sustainable Energy (28)

- Transformational Challenge Reactor (4)

- Transportation (23)

Media Contacts

The National Alliance for Water Innovation, a partnership of the Department of Energy’s Oak Ridge National Laboratory, other national labs, university and private sector partners, has been awarded a five-year, $100 million Energy-Water Desalination Hub by DOE to address water security issues in the United States.

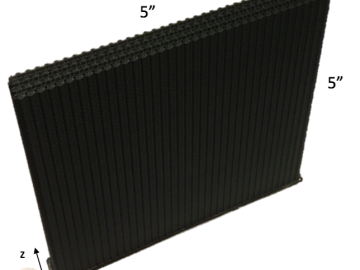

A team including Oak Ridge National Laboratory and University of Tennessee researchers demonstrated a novel 3D printing approach called Z-pinning that can increase the material’s strength and toughness by more than three and a half times compared to conventional additive manufacturing processes.

Craig Blue, a program director at the Department of Energy’s Oak Ridge National Laboratory, has been elected a 2019 fellow for SME (formerly known as the Society for Manufacturing Engineers).

Electro-Active Technologies, Inc., of Knoxville, Tenn., has exclusively licensed two biorefinery technologies invented and patented by the startup’s co-founders while working at the Department of Energy’s Oak Ridge National Laboratory. The technologies work as a system that converts organic waste into renewable hydrogen gas for use as a biofuel.

A detailed study by Oak Ridge National Laboratory estimated how much more—or less—energy United States residents might consume by 2050 relative to predicted shifts in seasonal weather patterns

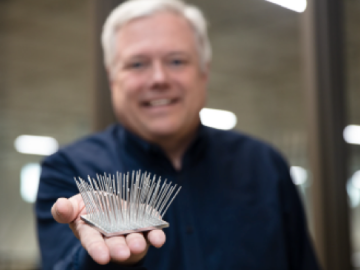

In the shifting landscape of global manufacturing, American ingenuity is once again giving U.S companies an edge with radical productivity improvements as a result of advanced materials and robotic systems developed at the Department of Energy’s Manufacturing Demonstration Facility (MDF) at Oak Ridge National Laboratory.

OAK RIDGE, Tenn., May 8, 2019—Oak Ridge National Laboratory and Lincoln Electric (NASDAQ: LECO) announced their continued collaboration on large-scale, robotic additive manufacturing technology at the Department of Energy’s Advanced Manufacturing InnovationXLab Summit.

When Scott Smith looks at a machine tool, he thinks not about what the powerful equipment used to shape metal can do – he’s imagining what it could do with the right added parts and strategies. As ORNL’s leader for a newly formed group, Machining and Machine Tool Research, Smith will have the opportunity to do just that.

Scientists at Oak Ridge National Laboratory have developed a low-cost, printed, flexible sensor that can wrap around power cables to precisely monitor electrical loads from household appliances to support grid operations.

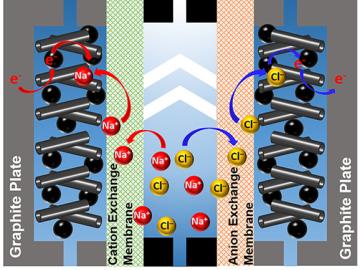

A team of scientists led by Oak Ridge National Laboratory used carbon nanotubes to improve a desalination process that attracts and removes ionic compounds such as salt from water using charged electrodes.