Filter News

Area of Research

News Topics

- (-) Artificial Intelligence (6)

- (-) Composites (4)

- 3-D Printing/Advanced Manufacturing (18)

- Advanced Reactors (6)

- Big Data (7)

- Bioenergy (3)

- Biology (4)

- Biomedical (1)

- Biotechnology (1)

- Buildings (4)

- Chemical Sciences (1)

- Clean Water (7)

- Climate Change (7)

- Computer Science (22)

- Coronavirus (3)

- Critical Materials (2)

- Cybersecurity (2)

- Decarbonization (1)

- Energy Storage (9)

- Environment (19)

- Fusion (5)

- Grid (8)

- High-Performance Computing (5)

- Isotopes (2)

- ITER (2)

- Machine Learning (3)

- Materials (17)

- Materials Science (16)

- Mathematics (1)

- Microscopy (5)

- Molten Salt (1)

- Nanotechnology (4)

- Net Zero (1)

- Neutron Science (12)

- Nuclear Energy (9)

- Physics (2)

- Polymers (2)

- Quantum Computing (1)

- Quantum Science (6)

- Space Exploration (6)

- Statistics (1)

- Summit (2)

- Sustainable Energy (22)

- Transportation (15)

Media Contacts

A research team at Oak Ridge National Laboratory have 3D printed a thermal protection shield, or TPS, for a capsule that will launch with the Cygnus cargo spacecraft as part of the supply mission to the International Space Station.

Oak Ridge National Laboratory researchers, in collaboration with Cincinnati Inc., demonstrated the potential for using multimaterials and recycled composites in large-scale applications by 3D printing a mold that replicated a single facet of a

Oak Ridge National Laboratory researchers combined additive manufacturing with conventional compression molding to produce high-performance thermoplastic composites reinforced with short carbon fibers.

Algorithms developed at Oak Ridge National Laboratory can greatly enhance X-ray computed tomography images of 3D-printed metal parts, resulting in more accurate, faster scans.

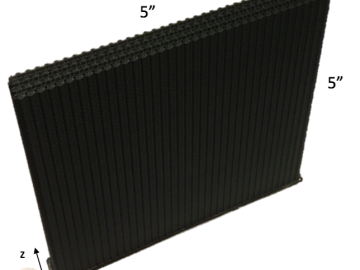

A team including Oak Ridge National Laboratory and University of Tennessee researchers demonstrated a novel 3D printing approach called Z-pinning that can increase the material’s strength and toughness by more than three and a half times compared to conventional additive manufacturing processes.

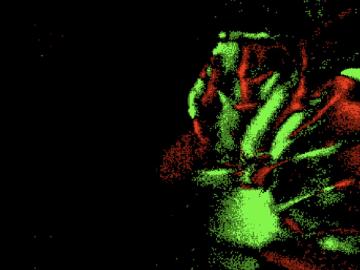

Oak Ridge National Laboratory is training next-generation cameras called dynamic vision sensors, or DVS, to interpret live information—a capability that has applications in robotics and could improve autonomous vehicle sensing.

Researchers at Oak Ridge National Laboratory are taking inspiration from neural networks to create computers that mimic the human brain—a quickly growing field known as neuromorphic computing.

A study led by Oak Ridge National Laboratory explored the interface between the Department of Veterans Affairs’ healthcare data system and the data itself to detect the likelihood of errors and designed an auto-surveillance tool

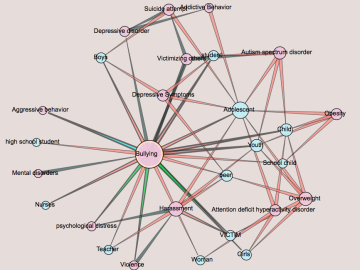

Oak Ridge National Laboratory is using artificial intelligence to analyze data from published medical studies associated with bullying to reveal the potential of broader impacts, such as mental illness or disease.

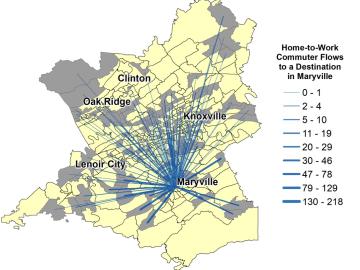

Oak Ridge National Laboratory geospatial scientists who study the movement of people are using advanced machine learning methods to better predict home-to-work commuting patterns.