Filter News

Area of Research

- (-) Clean Energy (48)

- Advanced Manufacturing (6)

- Biology and Environment (11)

- Building Technologies (1)

- Computational Biology (1)

- Computer Science (1)

- Fusion and Fission (3)

- Isotopes (1)

- Materials (8)

- Materials for Computing (9)

- National Security (1)

- Neutron Science (7)

- Supercomputing (6)

- Transportation Systems (1)

News Topics

- (-) Artificial Intelligence (1)

- (-) Composites (5)

- (-) Coronavirus (2)

- (-) Materials (17)

- (-) Sustainable Energy (24)

- (-) Transportation (16)

- 3-D Printing/Advanced Manufacturing (24)

- Advanced Reactors (1)

- Big Data (3)

- Bioenergy (3)

- Biology (5)

- Biomedical (1)

- Biotechnology (1)

- Buildings (11)

- Chemical Sciences (1)

- Clean Water (1)

- Climate Change (4)

- Computer Science (5)

- Critical Materials (3)

- Decarbonization (5)

- Energy Storage (20)

- Environment (12)

- Grid (8)

- High-Performance Computing (5)

- Materials Science (6)

- Mathematics (1)

- Microscopy (1)

- Nanotechnology (2)

- Net Zero (1)

- Neutron Science (2)

- Nuclear Energy (1)

- Polymers (3)

- Security (1)

- Space Exploration (1)

- Statistics (1)

- Summit (2)

Media Contacts

Through a consortium of Department of Energy national laboratories, ORNL scientists are applying their expertise to provide solutions that enable the commercialization of emission-free hydrogen fuel cell technology for heavy-duty

Oak Ridge National Laboratory scientists proved molybdenum titanium carbide, a refractory metal alloy that can withstand extreme temperature environments, can also be crack free and dense when produced with electron beam powder bed fusion.

A newly released dataset that tracks the movement of everything from food to gasoline across the United States by air, water, truck, rail and pipeline showed the value and tonnage of those goods rose significantly between 2012 and 2017.

A team of researchers at Oak Ridge National Laboratory and the University of Tennessee have developed a concrete mix that demonstrated high early strength within six hours of mixing, potentially doubling the production capacity for the precast industry.

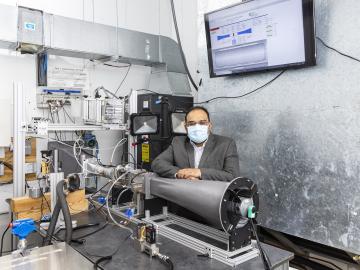

When Kashif Nawaz looks at a satellite map of the U.S., he sees millions of buildings that could hold a potential solution for the capture of carbon dioxide, a plentiful gas that can be harmful when excessive amounts are released into the atmosphere, raising the Earth’s temperature.

Scientists at Oak Ridge National Laboratory successfully demonstrated a technique to heal dendrites that formed in a solid electrolyte, resolving an issue that can hamper the performance of high energy-density, solid-state batteries.

Oak Ridge National Laboratory researchers combined additive manufacturing with conventional compression molding to produce high-performance thermoplastic composites reinforced with short carbon fibers.

Xin Sun has been selected as the associate laboratory director for the Energy Science and Technology Directorate, or ESTD, at the Department of Energy’s Oak Ridge National Laboratory.

A team of Oak Ridge National Laboratory researchers demonstrated that an additively manufactured hot stamping die – a tool used to create car body components – cooled faster than those produced by conventional manufacturing methods.

Twenty-seven ORNL researchers Zoomed into 11 middle schools across Tennessee during the annual Engineers Week in February. East Tennessee schools throughout Oak Ridge and Roane, Sevier, Blount and Loudon counties participated, with three West Tennessee schools joining in.