Filter News

Area of Research

News Topics

- (-) Biotechnology (5)

- (-) Isotopes (12)

- (-) Nuclear Energy (6)

- 3-D Printing/Advanced Manufacturing (26)

- Advanced Reactors (2)

- Artificial Intelligence (7)

- Big Data (5)

- Bioenergy (13)

- Biology (23)

- Biomedical (10)

- Buildings (13)

- Chemical Sciences (7)

- Clean Water (8)

- Climate Change (11)

- Composites (6)

- Computer Science (30)

- Coronavirus (10)

- Critical Materials (4)

- Cybersecurity (5)

- Decarbonization (7)

- Energy Storage (22)

- Environment (39)

- Exascale Computing (2)

- Frontier (4)

- Fusion (8)

- Grid (11)

- High-Performance Computing (19)

- ITER (4)

- Machine Learning (1)

- Materials (32)

- Materials Science (22)

- Mathematics (1)

- Mercury (3)

- Microscopy (10)

- Nanotechnology (10)

- National Security (7)

- Net Zero (1)

- Neutron Science (18)

- Physics (3)

- Polymers (5)

- Quantum Computing (5)

- Quantum Science (12)

- Security (3)

- Space Exploration (4)

- Statistics (1)

- Summit (9)

- Sustainable Energy (35)

- Transportation (21)

Media Contacts

Detecting the activity of CRISPR gene editing tools in organisms with the naked eye and an ultraviolet flashlight is now possible using technology developed at ORNL.

In experiment after experiment, the synthetic radioisotope actinium-225 has shown promise for targeting and attacking certain types of cancer cells.

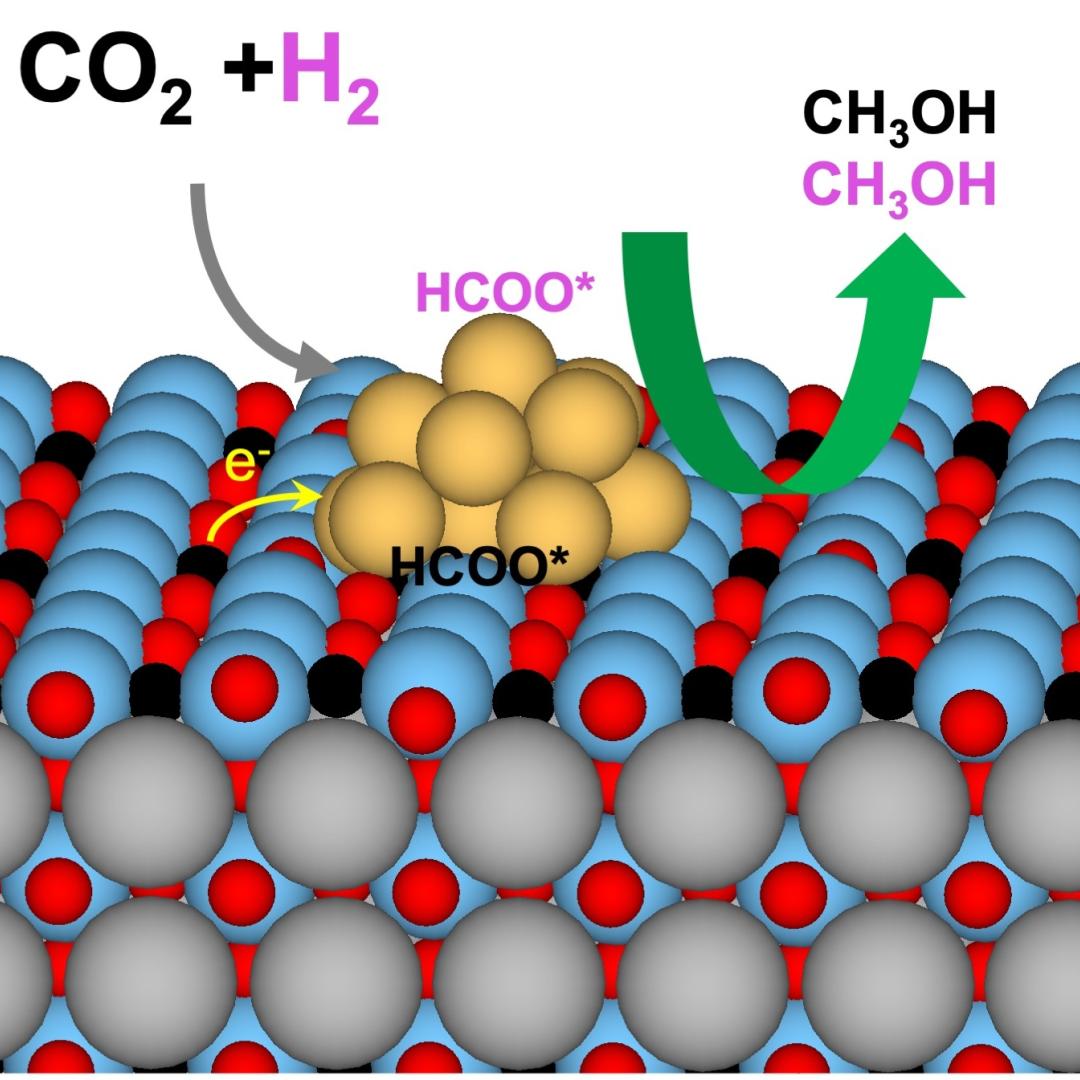

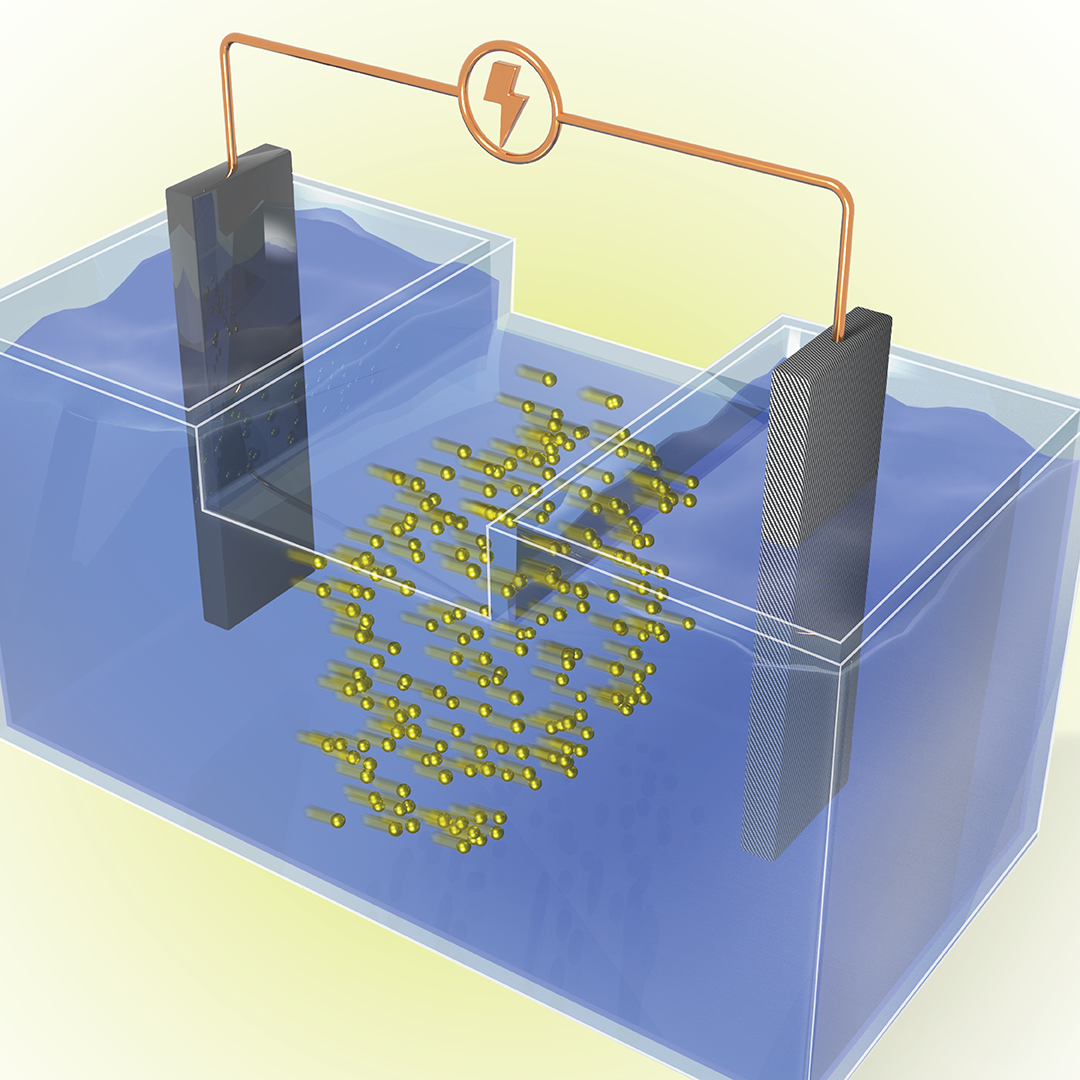

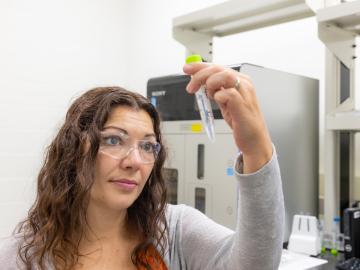

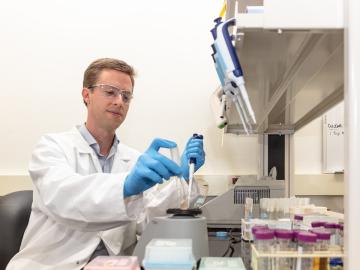

Carrie Eckert applies her skills as a synthetic biologist at ORNL to turn microorganisms into tiny factories that produce a variety of valuable fuels, chemicals and materials for the growing bioeconomy.

A 25-year career with the U.S. Navy, commanding combat missions overseas, brought Tom Kollie back to where he came from — ready to serve his country in a new way.

As a medical isotope, thorium-228 has a lot of potential — and Oak Ridge National Laboratory produces a lot.

Four first-of-a-kind 3D-printed fuel assembly brackets, produced at the Department of Energy’s Manufacturing Demonstration Facility at Oak Ridge National Laboratory, have been installed and are now under routine operating

An Oak Ridge National Laboratory researcher has invented a version of an isotope-separating device that can withstand extreme environments, including radiation and chemical solvents.

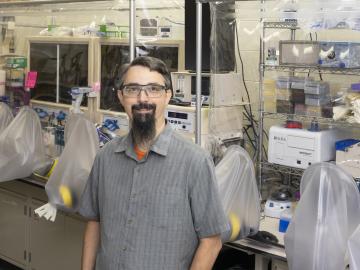

As a metabolic engineer at Oak Ridge National Laboratory, Adam Guss modifies microbes to perform the diverse processes needed to make sustainable biofuels and bioproducts.

In a step toward increasing the cost-effectiveness of renewable biofuels and bioproducts, scientists at ORNL discovered a microbial enzyme that degrades tough-to-break bonds in lignin, a waste product of biorefineries.

Kathy McCarthy, associate laboratory director for Fusion and Fission Energy and Science at the Department of Energy’s Oak Ridge National Laboratory, has been elected fellow of the American Nuclear Society for her nationally and internationally recognized leadership in nuclear energy and fusion.