Filter News

Area of Research

- Advanced Manufacturing (6)

- Biology and Environment (5)

- Building Technologies (1)

- Clean Energy (33)

- Computer Science (4)

- Electricity and Smart Grid (1)

- Fusion and Fission (7)

- Materials (5)

- Materials for Computing (5)

- Neutron Science (2)

- Quantum information Science (1)

- Sensors and Controls (1)

- Supercomputing (3)

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (19)

- (-) Advanced Reactors (1)

- (-) Big Data (3)

- (-) Bioenergy (4)

- (-) Fusion (7)

- (-) Grid (8)

- (-) Machine Learning (1)

- (-) Quantum Science (8)

- (-) Sustainable Energy (26)

- Artificial Intelligence (3)

- Biology (9)

- Biomedical (4)

- Biotechnology (2)

- Buildings (8)

- Chemical Sciences (5)

- Clean Water (5)

- Climate Change (8)

- Composites (6)

- Computer Science (16)

- Coronavirus (7)

- Critical Materials (4)

- Cybersecurity (4)

- Decarbonization (2)

- Energy Storage (14)

- Environment (16)

- Frontier (3)

- High-Performance Computing (10)

- Isotopes (6)

- ITER (3)

- Materials (27)

- Materials Science (15)

- Mathematics (1)

- Microscopy (7)

- Nanotechnology (7)

- National Security (3)

- Net Zero (1)

- Neutron Science (10)

- Nuclear Energy (2)

- Physics (1)

- Polymers (4)

- Quantum Computing (4)

- Security (1)

- Space Exploration (3)

- Statistics (1)

- Summit (5)

- Transportation (12)

Media Contacts

The Department of Energy’s Oak Ridge National Laboratory has licensed its award-winning artificial intelligence software system, the Multinode Evolutionary Neural Networks for Deep Learning, to General Motors for use in vehicle technology and design.

Oak Ridge National Laboratory scientists proved molybdenum titanium carbide, a refractory metal alloy that can withstand extreme temperature environments, can also be crack free and dense when produced with electron beam powder bed fusion.

Using complementary computing calculations and neutron scattering techniques, researchers from the Department of Energy’s Oak Ridge and Lawrence Berkeley national laboratories and the University of California, Berkeley, discovered the existence of an elusive type of spin dynamics in a quantum mechanical system.

Oak Ridge National Laboratory researchers combined additive manufacturing with conventional compression molding to produce high-performance thermoplastic composites reinforced with short carbon fibers.

Xin Sun has been selected as the associate laboratory director for the Energy Science and Technology Directorate, or ESTD, at the Department of Energy’s Oak Ridge National Laboratory.

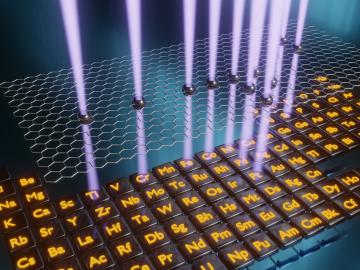

Oak Ridge National Laboratory scientists demonstrated that an electron microscope can be used to selectively remove carbon atoms from graphene’s atomically thin lattice and stitch transition-metal dopant atoms in their place.

A team of Oak Ridge National Laboratory researchers demonstrated that an additively manufactured hot stamping die – a tool used to create car body components – cooled faster than those produced by conventional manufacturing methods.

A method developed at Oak Ridge National Laboratory to print high-fidelity, passive sensors for energy applications can reduce the cost of monitoring critical power grid assets.

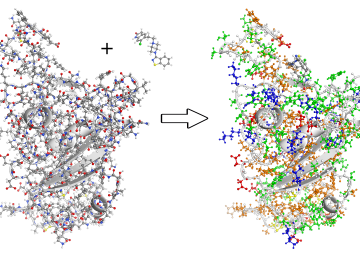

To better understand the spread of SARS-CoV-2, the virus that causes COVID-19, Oak Ridge National Laboratory researchers have harnessed the power of supercomputers to accurately model the spike protein that binds the novel coronavirus to a human cell receptor.

Oak Ridge National Laboratory researchers have demonstrated that a new class of superalloys made of cobalt and nickel remains crack-free and defect-resistant in extreme heat, making them conducive for use in metal-based 3D printing applications.