Filter News

Area of Research

News Topics

- (-) 3-D Printing/Advanced Manufacturing (12)

- (-) Buildings (16)

- Advanced Reactors (4)

- Artificial Intelligence (14)

- Big Data (9)

- Bioenergy (19)

- Biology (28)

- Biomedical (6)

- Biotechnology (3)

- Chemical Sciences (15)

- Clean Water (5)

- Climate Change (26)

- Composites (3)

- Computer Science (20)

- Coronavirus (9)

- Critical Materials (4)

- Cybersecurity (7)

- Decarbonization (21)

- Element Discovery (1)

- Energy Storage (25)

- Environment (36)

- Exascale Computing (8)

- Fossil Energy (1)

- Frontier (10)

- Fusion (7)

- Grid (13)

- High-Performance Computing (16)

- Hydropower (8)

- Irradiation (1)

- Isotopes (4)

- ITER (2)

- Machine Learning (10)

- Materials (37)

- Materials Science (16)

- Mercury (1)

- Microscopy (13)

- Nanotechnology (9)

- National Security (17)

- Net Zero (2)

- Neutron Science (12)

- Nuclear Energy (10)

- Partnerships (8)

- Physics (10)

- Polymers (5)

- Quantum Computing (7)

- Quantum Science (9)

- Security (4)

- Simulation (6)

- Space Exploration (4)

- Summit (7)

- Sustainable Energy (25)

- Transformational Challenge Reactor (2)

- Transportation (10)

Media Contacts

Researchers at the Department of Energy’s Oak Ridge National Laboratory and their technologies have received seven 2022 R&D 100 Awards, plus special recognition for a battery-related green technology product.

Oak Ridge National Laboratory researchers demonstrated that microchannel heat exchangers in heating, ventilation and air conditioning units can keep refrigerants evenly and continually distributed by inserting a device called a piezoelectric-driven

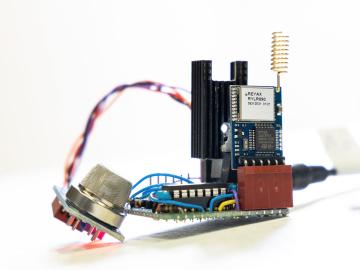

Oak Ridge National Laboratory researchers demonstrated that an electrochemical sensor paired with a transmitter not only detects propane leaks within seconds, but it can also send a signal to alert emergency services.

ORNL researchers have developed an upcycling approach that adds value to discarded plastics for reuse in additive manufacturing, or 3D printing.

How an Alvin M. Weinberg Fellow is increasing security for critical infrastructure components

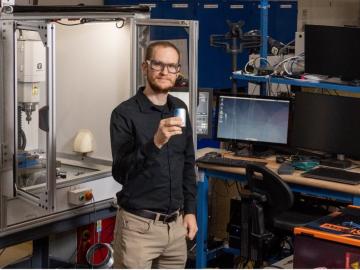

When Andrew Sutton arrived at ORNL in late 2020, he knew the move would be significant in more ways than just a change in location.

A prototype cooking appliance developed by Oak Ridge National Laboratory uses a 50% blend of hydrogen and natural gas, offering an alternative to safely reduce emissions that contribute to the nation’s carbon footprint.

Oak Ridge National Laboratory scientist Amy Elliott is one of 120 women featured in a new exhibit, IfThenSheCan, at the Smithsonian to commemorate Women's History Month. A life-size 3D printed statue of Elliott, a manufacturing scientist, is on display in the Smithsonian Castle in Washington, D.C.

Every day, hundreds of thousands of commuters across the country travel from houses, apartments and other residential spaces to commercial buildings — from offices and schools to gyms and grocery stores.

Oak Ridge National Laboratory researchers have developed a novel solution to reduce the environmental impact of natural gas-condensing furnaces commonly used in U.S. homes.