Filter News

Area of Research

News Topics

- (-) 3-D Printing/Advanced Manufacturing (20)

- (-) Biotechnology (6)

- (-) Buildings (14)

- Advanced Reactors (3)

- Artificial Intelligence (26)

- Big Data (10)

- Bioenergy (22)

- Biology (29)

- Biomedical (7)

- Chemical Sciences (24)

- Clean Water (5)

- Climate Change (31)

- Composites (6)

- Computer Science (23)

- Coronavirus (4)

- Critical Materials (6)

- Cybersecurity (9)

- Decarbonization (30)

- Education (3)

- Emergency (1)

- Energy Storage (21)

- Environment (43)

- Exascale Computing (15)

- Fossil Energy (2)

- Frontier (19)

- Fusion (9)

- Grid (16)

- High-Performance Computing (33)

- Hydropower (3)

- Irradiation (2)

- Isotopes (11)

- Machine Learning (15)

- Materials (59)

- Materials Science (16)

- Mathematics (2)

- Mercury (2)

- Microelectronics (2)

- Microscopy (7)

- Molten Salt (1)

- Nanotechnology (7)

- National Security (21)

- Net Zero (5)

- Neutron Science (32)

- Nuclear Energy (21)

- Partnerships (24)

- Physics (14)

- Polymers (4)

- Quantum Computing (12)

- Quantum Science (9)

- Renewable Energy (2)

- Security (3)

- Simulation (29)

- Software (1)

- Space Exploration (4)

- Summit (9)

- Sustainable Energy (17)

- Transportation (18)

Media Contacts

Researchers at ORNL became the first to 3D-print large rotating steam turbine blades for generating energy in power plants.

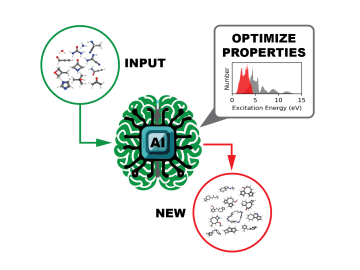

A team of computational scientists at ORNL has generated and released datasets of unprecedented scale that provide the ultraviolet visible spectral properties of over 10 million organic molecules.

Four scientists affiliated with ORNL were named Battelle Distinguished Inventors during the lab’s annual Innovation Awards on Dec. 1 in recognition of being granted 14 or more United States patents.

Karen White, who works in ORNL’s Neutron Science Directorate, has been honored with a Lifetime Achievement Award.

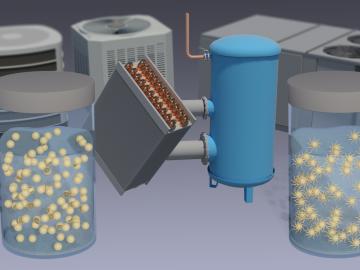

ORNL researchers demonstrated that an additive made from polymers and electrolytes improves the thermal performance and stability of salt hydrate phase change materials, or PCMs, a finding that could advance their integration into carbon-reducing heat pumps.

The Hub & Spoke Sustainable Materials & Manufacturing Alliance for Renewable Technologies, or SM2ART, program has been honored with the composites industry’s Combined Strength Award at the Composites and Advanced Materials Expo, or CAMX, 2023 in Atlanta. This distinction goes to the team that applies their knowledge, resources and talent to solve a problem by making the best use of composites materials.

Walters is working with a team of geographers, linguists, economists, data scientists and software engineers to apply cultural knowledge and patterns to open-source data in an effort to document and report patterns of human movement through previously unstudied spaces.

In fiscal year 2023 — Oct. 1–Sept. 30, 2023 — Oak Ridge National Laboratory was awarded more than $8 million in technology maturation funding through the Department of Energy’s Technology Commercialization Fund, or TCF.

An Oak Ridge National Laboratory-developed advanced manufacturing technology, AMCM, was recently licensed by Orbital Composites and enables the rapid production of composite-based components, which could accelerate the decarbonization of vehicles

Researchers at the Department of Energy’s Oak Ridge National Laboratory, in collaboration with NASA, are taking additive manufacturing to the final frontier by 3D printing the same kind of wheel as the design used by NASA for its robotic lunar rover, demonstrating the technology for specialized parts needed for space exploration.