Filter News

Area of Research

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (16)

- (-) Artificial Intelligence (29)

- (-) Climate Change (25)

- (-) Cybersecurity (6)

- (-) Frontier (19)

- (-) Isotopes (14)

- (-) Neutron Science (25)

- Advanced Reactors (2)

- Big Data (9)

- Bioenergy (16)

- Biology (25)

- Biomedical (6)

- Biotechnology (4)

- Buildings (13)

- Chemical Sciences (16)

- Clean Water (5)

- Composites (4)

- Computer Science (22)

- Coronavirus (1)

- Critical Materials (2)

- Decarbonization (29)

- Education (1)

- Emergency (2)

- Energy Storage (10)

- Environment (39)

- Exascale Computing (16)

- Fossil Energy (4)

- Fusion (13)

- Grid (14)

- High-Performance Computing (27)

- Hydropower (2)

- Machine Learning (15)

- Materials (31)

- Materials Science (18)

- Mathematics (4)

- Mercury (1)

- Microelectronics (2)

- Microscopy (5)

- Nanotechnology (5)

- National Security (25)

- Net Zero (6)

- Nuclear Energy (21)

- Partnerships (15)

- Physics (13)

- Polymers (3)

- Quantum Computing (14)

- Quantum Science (15)

- Renewable Energy (1)

- Security (3)

- Simulation (28)

- Software (1)

- Space Exploration (7)

- Statistics (1)

- Summit (11)

- Sustainable Energy (19)

- Transportation (7)

Media Contacts

ORNL hosted its fourth Artificial Intelligence for Robust Engineering and Science, or AIRES, workshop from April 18-20. Over 100 attendees from government, academia and industry convened to identify research challenges and investment areas, carving the future of the discipline.

Yarom Polsky, director of the Manufacturing Science Division, or MSD, at the Department of Energy’s Oak Ridge National Laboratory, has been elected a Fellow of the American Society of Mechanical Engineers, or ASME.

Wildfires have shaped the environment for millennia, but they are increasing in frequency, range and intensity in response to a hotter climate. The phenomenon is being incorporated into high-resolution simulations of the Earth’s climate by scientists at the Department of Energy’s Oak Ridge National Laboratory, with a mission to better understand and predict environmental change.

When geoinformatics engineering researchers at the Department of Energy’s Oak Ridge National Laboratory wanted to better understand changes in land areas and points of interest around the world, they turned to the locals — their data, at least.

Early experiments at the Department of Energy’s Oak Ridge National Laboratory have revealed significant benefits to a dry battery manufacturing process. This eliminates the use of solvents and is more affordable, while showing promise for delivering a battery that is durable, less weighed down by inactive elements, and able to maintain a high capacity after use.

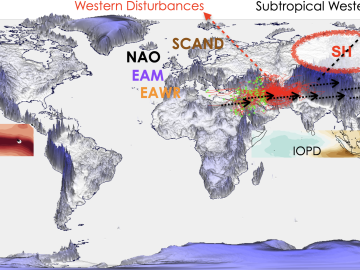

As extreme weather devastates communities worldwide, scientists are using modeling and simulation to understand how climate change impacts the frequency and intensity of these events. Although long-term climate projections and models are important, they are less helpful for short-term prediction of extreme weather that may rapidly displace thousands of people or require emergency aid.

With the world’s first exascale supercomputer now fully open for scientific business, researchers can thank the early users who helped get the machine up to speed.

Researchers at the Department of Energy’s Oak Ridge National Laboratory were the first to use neutron reflectometry to peer inside a working solid-state battery and monitor its electrochemistry.

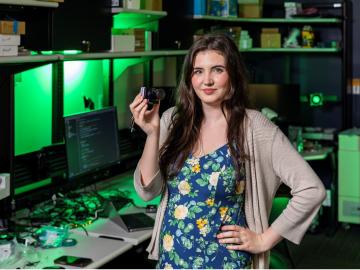

Tristen Mullins enjoys the hidden side of computers. As a signals processing engineer for ORNL, she tries to uncover information hidden in components used on the nation’s power grid — information that may be susceptible to cyberattacks.

Ken Herwig's scientific drive crystallized in his youth when he solved a tough algebra word problem in his head while tossing newspapers from his bicycle. He said the joy he felt in that moment as a teenager fueled his determination to conquer mathematical mysteries. And he did.