Filter News

Area of Research

- (-) Advanced Manufacturing (7)

- (-) Fuel Cycle Science and Technology (2)

- Biological Systems (3)

- Biology and Environment (119)

- Biology and Soft Matter (4)

- Building Technologies (3)

- Chemical and Engineering Materials (3)

- Chemistry and Physics at Interfaces (7)

- Clean Energy (208)

- Climate and Environmental Systems (7)

- Computational Biology (1)

- Computational Chemistry (5)

- Computational Engineering (2)

- Computer Science (4)

- Data (1)

- Earth Sciences (1)

- Electricity and Smart Grid (2)

- Energy Frontier Research Centers (7)

- Energy Sciences (2)

- Functional Materials for Energy (10)

- Fusion and Fission (43)

- Fusion Energy (7)

- Geographic Information Science and Technology (1)

- Isotopes (24)

- Materials (186)

- Materials Characterization (2)

- Materials for Computing (17)

- Materials Synthesis from Atoms to Systems (8)

- Materials Under Extremes (8)

- National Security (53)

- Neutron Data Analysis and Visualization (2)

- Neutron Science (83)

- Nuclear Science and Technology (35)

- Quantum Condensed Matter (3)

- Quantum information Science (5)

- Renewable Energy (2)

- Sensors and Controls (2)

- Supercomputing (172)

- Transportation Systems (6)

News Type

Media Contacts

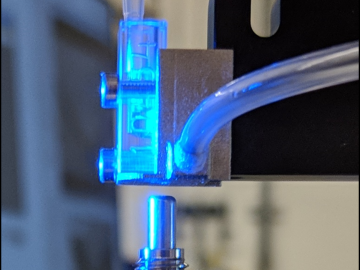

Scientists at ORNL have developed 3D-printed collimator techniques that can be used to custom design collimators that better filter out noise during different types of neutron scattering experiments

For years, Duane Starr led workshops at ORNL to help others from across the U.S. government understand uranium processing technologies. After his retirement, Starr donated a 5-foot-tall working model, built in his garage, that demonstrates vibration harmonics, consistent with operation of a super critical gas centrifuge rotor, a valuable resource to ongoing ORNL-led workshops.

The ExOne Company, the global leader in industrial sand and metal 3D printers using binder jetting technology, announced it has reached a commercial license agreement with Oak Ridge National Laboratory to 3D print parts in aluminum-infiltrated boron carbide.

The Society of Manufacturing Engineers, known as SME, has named William Peter, director of Oak Ridge National Laboratory’s Manufacturing Demonstration Facility in the Energy and Environmental Sciences Directorate, among its 2020 College of SME Fellows.

Researchers at the Department of Energy’s Oak Ridge National Laboratory have received five 2019 R&D 100 Awards, increasing the lab’s total to 221 since the award’s inception in 1963.

While serving in Kandahar, Afghanistan, U.S. Navy construction mechanic Matthew Sallas may not have imagined where his experience would take him next. But researchers at Oak Ridge National Laboratory certainly had the future in mind as they were creating programs to train men and wome...

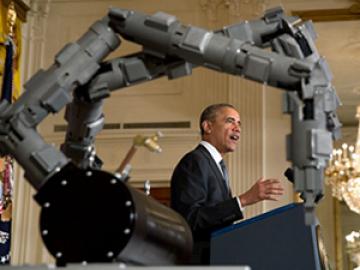

University of Tennessee (UT)-Oak Ridge National Laboratory Governor's Chair for Advanced Manufacturing Suresh Babu will lead the University of Tennessee's effort as part of a Detroit-based Lightweight and Modern Metals Manufacturing Innovation institute announced by President Obama on Feb. 25.