Filter News

Area of Research

- Advanced Manufacturing (1)

- Biology and Environment (2)

- Clean Energy (46)

- Computer Science (2)

- Energy Sciences (1)

- Fusion and Fission (17)

- Fusion Energy (11)

- Isotopes (1)

- Materials (21)

- Materials for Computing (4)

- National Security (2)

- Neutron Science (6)

- Nuclear Science and Technology (11)

- Quantum information Science (7)

- Supercomputing (16)

News Type

News Topics

- (-) Energy Storage (65)

- (-) Fusion (41)

- (-) Molten Salt (6)

- (-) Quantum Science (41)

- 3-D Printing/Advanced Manufacturing (72)

- Advanced Reactors (22)

- Artificial Intelligence (60)

- Big Data (41)

- Bioenergy (66)

- Biology (76)

- Biomedical (40)

- Biotechnology (15)

- Buildings (42)

- Chemical Sciences (33)

- Clean Water (28)

- Climate Change (74)

- Composites (16)

- Computer Science (126)

- Coronavirus (29)

- Critical Materials (15)

- Cybersecurity (17)

- Decarbonization (57)

- Education (1)

- Emergency (2)

- Environment (150)

- Exascale Computing (26)

- Fossil Energy (4)

- Frontier (26)

- Grid (45)

- High-Performance Computing (54)

- Hydropower (11)

- Irradiation (2)

- Isotopes (33)

- ITER (5)

- Machine Learning (33)

- Materials (77)

- Materials Science (86)

- Mathematics (7)

- Mercury (10)

- Microelectronics (2)

- Microscopy (34)

- Nanotechnology (32)

- National Security (41)

- Net Zero (9)

- Neutron Science (77)

- Nuclear Energy (78)

- Partnerships (17)

- Physics (37)

- Polymers (20)

- Quantum Computing (24)

- Renewable Energy (1)

- Security (13)

- Simulation (37)

- Software (1)

- Space Exploration (22)

- Statistics (1)

- Summit (36)

- Sustainable Energy (90)

- Transformational Challenge Reactor (3)

- Transportation (67)

Media Contacts

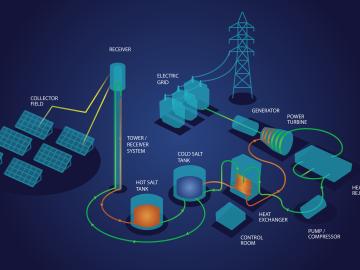

Oak Ridge National Laboratory scientists recently demonstrated a low-temperature, safe route to purifying molten chloride salts that minimizes their ability to corrode metals. This method could make the salts useful for storing energy generated from the sun’s heat.

Scientists at Oak Ridge National Laboratory are using ultrasounds — usually associated with medical imaging — to check the health of an operating battery. The technique uses sensors as small as a thumbnail, which could be attached to a lithium-ion battery inside a car.

A crowd of investors and supporters turned out for last week’s Innovation Crossroads Showcase at the Knoxville Chamber as part of Innov865 Week. Sponsored by ORNL and the Tennessee Advanced Energy Business Council, the event celebrated deep-tech entrepreneurs and the Oak Ridge Corridor as a growing energy innovation hub for the nation.

Researchers in the geothermal energy industry are joining forces with fusion experts at ORNL to repurpose gyrotron technology, a tool used in fusion. Gyrotrons produce high-powered microwaves to heat up fusion plasmas.

Five National Quantum Information Science Research Centers are leveraging the behavior of nature at the smallest scales to develop technologies for science’s most complex problems.

Travis Humble has been named director of the Quantum Science Center headquartered at ORNL. The QSC is a multi-institutional partnership that spans industry, academia and government institutions and is tasked with uncovering the full potential of quantum materials, sensors and algorithms.

Mechanical engineer Marm Dixit’s work is all about getting electricity to flow efficiently from one end of a solid-state battery to the other. It’s a high-stakes problem

Practical fusion energy is not just a dream at ORNL. Experts in fusion and material science are working together to develop solutions that will make a fusion pilot plant — and ultimately carbon-free, abundant fusion electricity — possible.

To achieve practical energy from fusion, extreme heat from the fusion system “blanket” component must be extracted safely and efficiently. ORNL fusion experts are exploring how tiny 3D-printed obstacles placed inside the narrow pipes of a custom-made cooling system could be a solution for removing heat from the blanket.

Several electrolyte and thin-film coating technologies, developed at Oak Ridge National Laboratory, have been licensed by BTRY, a battery technology company based in Virginia, to make batteries with increased energy density, at lower cost, and with an improved safety profile in crashes.