Filter News

Area of Research

- Advanced Manufacturing (3)

- Biology and Environment (13)

- Clean Energy (58)

- Computational Engineering (1)

- Computer Science (4)

- Fusion and Fission (5)

- Fusion Energy (1)

- Materials (30)

- Materials for Computing (3)

- National Security (14)

- Neutron Science (9)

- Nuclear Science and Technology (1)

- Quantum information Science (1)

- Supercomputing (27)

- Transportation Systems (2)

News Type

News Topics

- (-) Composites (15)

- (-) Fossil Energy (4)

- (-) Frontier (25)

- (-) Machine Learning (32)

- (-) Physics (32)

- (-) Security (12)

- (-) Transportation (62)

- 3-D Printing/Advanced Manufacturing (68)

- Advanced Reactors (21)

- Artificial Intelligence (59)

- Big Data (38)

- Bioenergy (65)

- Biology (75)

- Biomedical (39)

- Biotechnology (14)

- Buildings (37)

- Chemical Sciences (31)

- Clean Water (27)

- Climate Change (70)

- Computer Science (121)

- Coronavirus (28)

- Critical Materials (14)

- Cybersecurity (17)

- Decarbonization (53)

- Education (1)

- Emergency (2)

- Energy Storage (59)

- Environment (144)

- Exascale Computing (26)

- Fusion (39)

- Grid (43)

- High-Performance Computing (54)

- Hydropower (11)

- Irradiation (2)

- Isotopes (32)

- ITER (5)

- Materials (76)

- Materials Science (77)

- Mathematics (7)

- Mercury (10)

- Microelectronics (2)

- Microscopy (31)

- Molten Salt (6)

- Nanotechnology (28)

- National Security (38)

- Net Zero (9)

- Neutron Science (74)

- Nuclear Energy (73)

- Partnerships (17)

- Polymers (17)

- Quantum Computing (24)

- Quantum Science (40)

- Renewable Energy (1)

- Simulation (37)

- Software (1)

- Space Exploration (22)

- Statistics (1)

- Summit (36)

- Sustainable Energy (87)

- Transformational Challenge Reactor (3)

Media Contacts

Researchers at Oak Ridge National Laboratory have developed a nationwide modeling tool to help infrastructure planners decide where and when to locate electric vehicle charging stations along interstate highways. The goal is to encourage the adoption of EVs for cross-country travel.

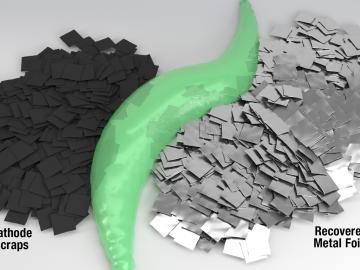

Scientists at Oak Ridge National Laboratory have developed a solvent that results in a more environmentally friendly process to recover valuable materials from used lithium-ion batteries, supports a stable domestic supply chain for new batteries

Consumer buy-in is key to the future of a decarbonized transportation sector in which electric vehicles largely replace today’s conventionally fueled cars and trucks.

Deborah Frincke, one of the nation’s preeminent computer scientists and cybersecurity experts, serves as associate laboratory director of ORNL’s National Security Science Directorate. Credit: Carlos Jones/ORNL, U.S. Dept. of Energy

Oak Ridge National Laboratory researchers, in collaboration with Cincinnati Inc., demonstrated the potential for using multimaterials and recycled composites in large-scale applications by 3D printing a mold that replicated a single facet of a

Through a consortium of Department of Energy national laboratories, ORNL scientists are applying their expertise to provide solutions that enable the commercialization of emission-free hydrogen fuel cell technology for heavy-duty

A newly released dataset that tracks the movement of everything from food to gasoline across the United States by air, water, truck, rail and pipeline showed the value and tonnage of those goods rose significantly between 2012 and 2017.

Nuclear physicist Caroline Nesaraja of the Department of Energy’s Oak Ridge National Laboratory evaluates nuclear data vital to applied and basic sciences.

Scientists at Oak Ridge National Laboratory successfully demonstrated a technique to heal dendrites that formed in a solid electrolyte, resolving an issue that can hamper the performance of high energy-density, solid-state batteries.

Oak Ridge National Laboratory researchers combined additive manufacturing with conventional compression molding to produce high-performance thermoplastic composites reinforced with short carbon fibers.