Filter News

Area of Research

- Advanced Manufacturing (14)

- Biology and Environment (4)

- Building Technologies (4)

- Clean Energy (68)

- Computer Science (1)

- Fusion and Fission (4)

- Fusion Energy (1)

- Materials (12)

- Materials for Computing (2)

- National Security (2)

- Neutron Science (3)

- Nuclear Science and Technology (2)

- Supercomputing (4)

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (66)

- (-) Buildings (35)

- (-) Statistics (1)

- Advanced Reactors (21)

- Artificial Intelligence (58)

- Big Data (36)

- Bioenergy (64)

- Biology (74)

- Biomedical (39)

- Biotechnology (13)

- Chemical Sciences (29)

- Clean Water (27)

- Climate Change (68)

- Composites (15)

- Computer Science (119)

- Coronavirus (28)

- Critical Materials (13)

- Cybersecurity (17)

- Decarbonization (51)

- Education (1)

- Emergency (2)

- Energy Storage (59)

- Environment (143)

- Exascale Computing (25)

- Fossil Energy (4)

- Frontier (24)

- Fusion (37)

- Grid (43)

- High-Performance Computing (53)

- Hydropower (11)

- Irradiation (2)

- Isotopes (30)

- ITER (5)

- Machine Learning (31)

- Materials (75)

- Materials Science (75)

- Mathematics (6)

- Mercury (10)

- Microelectronics (2)

- Microscopy (31)

- Molten Salt (6)

- Nanotechnology (28)

- National Security (36)

- Net Zero (9)

- Neutron Science (73)

- Nuclear Energy (70)

- Partnerships (15)

- Physics (30)

- Polymers (17)

- Quantum Computing (22)

- Quantum Science (38)

- Renewable Energy (1)

- Security (11)

- Simulation (35)

- Software (1)

- Space Exploration (22)

- Summit (36)

- Sustainable Energy (87)

- Transformational Challenge Reactor (3)

- Transportation (62)

Media Contacts

Oak Ridge National Laboratory scientists ingeniously created a sustainable, soft material by combining rubber with woody reinforcements and incorporating “smart” linkages between the components that unlock on demand.

Momentum for manufacturing innovation in the United States got a boost during the inaugural MDF Innovation Days, held recently at the U.S. Department of Energy Manufacturing Demonstration Facility at Oak Ridge National Laboratory.

A technology developed by Oak Ridge National Laboratory works to keep food refrigerated with phase change materials, or PCMs, while reducing carbon emissions by 30%.

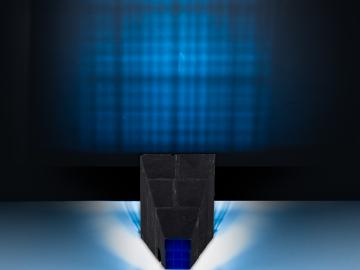

Simulations performed on the Summit supercomputer at ORNL are cutting through that time and expense by helping researchers digitally customize the ideal alloy.

Helping hundreds of manufacturing industries and water-power facilities across the U.S. increase energy efficiency requires a balance of teaching and training, blended with scientific guidance and technical expertise. It’s a formula for success that ORNL researchers have been providing to DOE’s Better Plants Program for more than a decade.

Rishi Pillai and his research team from ORNL will receive a Best Paper award from the American Society of Mechanical Engineers International Gas Turbine Institute in June at the Turbo Expo 2024 in London.

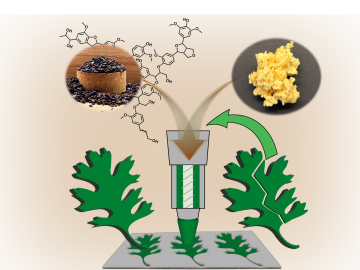

ORNL’s Erin Webb is co-leading a new Circular Bioeconomy Systems Convergent Research Initiative focused on advancing production and use of renewable carbon from Tennessee to meet societal needs.

Shift Thermal, a member of Innovation Crossroads’ first cohort of fellows, is commercializing advanced ice thermal energy storage for HVAC, shifting the cooling process to be more sustainable, cost-effective and resilient. Shift Thermal wants to enable a lower-cost, more-efficient thermal energy storage method to provide long-duration resilient cooling when the electric grid is down.

Three ORNL intellectual property projects with industry partners have advanced in DOE's Office of Technology Transitions Making Advanced Technology Commercialization Harmonized, or Lab MATCH, prize, which encourages entrepreneurs to find actionable pathways that bring lab-developed intellectual property to market.

Scientists at ORNL have developed 3D-printed collimator techniques that can be used to custom design collimators that better filter out noise during different types of neutron scattering experiments