Filter News

Area of Research

News Type

News Topics

- (-) Composites (15)

- (-) Coronavirus (28)

- (-) Exascale Computing (26)

- (-) Fusion (39)

- (-) Isotopes (32)

- (-) Molten Salt (6)

- (-) Space Exploration (22)

- 3-D Printing/Advanced Manufacturing (68)

- Advanced Reactors (21)

- Artificial Intelligence (59)

- Big Data (38)

- Bioenergy (65)

- Biology (75)

- Biomedical (39)

- Biotechnology (14)

- Buildings (37)

- Chemical Sciences (31)

- Clean Water (27)

- Climate Change (70)

- Computer Science (121)

- Critical Materials (14)

- Cybersecurity (17)

- Decarbonization (53)

- Education (1)

- Emergency (2)

- Energy Storage (59)

- Environment (144)

- Fossil Energy (4)

- Frontier (25)

- Grid (43)

- High-Performance Computing (54)

- Hydropower (11)

- Irradiation (2)

- ITER (5)

- Machine Learning (32)

- Materials (76)

- Materials Science (77)

- Mathematics (7)

- Mercury (10)

- Microelectronics (2)

- Microscopy (31)

- Nanotechnology (28)

- National Security (38)

- Net Zero (9)

- Neutron Science (74)

- Nuclear Energy (73)

- Partnerships (17)

- Physics (32)

- Polymers (17)

- Quantum Computing (24)

- Quantum Science (40)

- Renewable Energy (1)

- Security (12)

- Simulation (37)

- Software (1)

- Statistics (1)

- Summit (36)

- Sustainable Energy (87)

- Transformational Challenge Reactor (3)

- Transportation (62)

Media Contacts

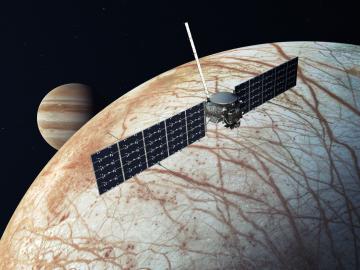

Researchers from NASA’s Jet Propulsion Laboratory and Oak Ridge National Laboratory successfully created amorphous ice, similar to ice in interstellar space and on icy worlds in our solar system. They documented that its disordered atomic behavior is unlike any ice on Earth.

For years Brenda Smith found fulfillment working with nuclear batteries, a topic she’s been researching as a chemist at Oak Ridge National Laboratory.

Oak Ridge National Laboratory researchers, in collaboration with Cincinnati Inc., demonstrated the potential for using multimaterials and recycled composites in large-scale applications by 3D printing a mold that replicated a single facet of a

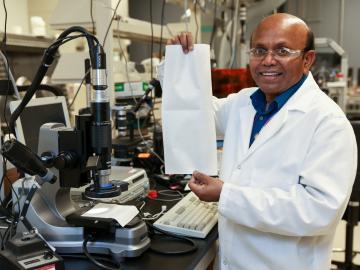

When COVID-19 was declared a pandemic in March 2020, Oak Ridge National Laboratory’s Parans Paranthaman suddenly found himself working from home like millions of others.

Oak Ridge National Laboratory researchers combined additive manufacturing with conventional compression molding to produce high-performance thermoplastic composites reinforced with short carbon fibers.

A new method developed at Oak Ridge National Laboratory proves one effort’s trash is another’s valuable isotope. One of the byproducts of the lab’s national plutonium-238 production program is promethium-147, a rare isotope used in nuclear batteries and to measure the thickness of materials.

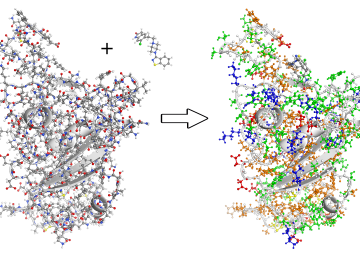

To better understand the spread of SARS-CoV-2, the virus that causes COVID-19, Oak Ridge National Laboratory researchers have harnessed the power of supercomputers to accurately model the spike protein that binds the novel coronavirus to a human cell receptor.

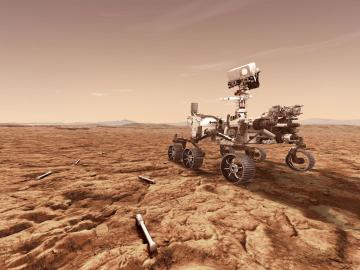

On Feb. 18, the world will be watching as NASA’s Perseverance rover makes its final descent into Jezero Crater on the surface of Mars. Mars 2020 is the first NASA mission that uses plutonium-238 produced at the Department of Energy’s Oak Ridge National Laboratory.

From the helm of a one-of-a-kind organization that brings nuclear fusion and fission expertise together to pave the way to expanding carbon-free energy, Kathy McCarthy can trace the first step of her engineering career back to

A better way of welding targets for Oak Ridge National Laboratory’s plutonium-238 production has sped up the process and improved consistency and efficiency. This advancement will ultimately benefit the lab’s goal to make enough Pu-238 – the isotope that powers NASA’s deep space missions – to yield 1.5 kilograms of plutonium oxide annually by 2026.