Filter News

Area of Research

News Topics

- (-) Advanced Reactors (8)

- (-) Biotechnology (11)

- (-) Molten Salt (1)

- 3-D Printing/Advanced Manufacturing (42)

- Artificial Intelligence (48)

- Big Data (27)

- Bioenergy (51)

- Biology (60)

- Biomedical (29)

- Buildings (19)

- Chemical Sciences (25)

- Clean Water (14)

- Climate Change (50)

- Composites (8)

- Computer Science (87)

- Coronavirus (17)

- Critical Materials (4)

- Cybersecurity (14)

- Decarbonization (46)

- Education (1)

- Emergency (2)

- Energy Storage (29)

- Environment (104)

- Exascale Computing (27)

- Fossil Energy (4)

- Frontier (25)

- Fusion (31)

- Grid (25)

- High-Performance Computing (45)

- Hydropower (5)

- Isotopes (27)

- ITER (2)

- Machine Learning (22)

- Materials (43)

- Materials Science (46)

- Mathematics (7)

- Mercury (7)

- Microelectronics (2)

- Microscopy (20)

- Nanotechnology (16)

- National Security (39)

- Net Zero (8)

- Neutron Science (47)

- Nuclear Energy (55)

- Partnerships (18)

- Physics (29)

- Polymers (8)

- Quantum Computing (21)

- Quantum Science (30)

- Renewable Energy (1)

- Security (11)

- Simulation (32)

- Software (1)

- Space Exploration (12)

- Statistics (1)

- Summit (31)

- Sustainable Energy (47)

- Transformational Challenge Reactor (3)

- Transportation (27)

Media Contacts

John Lagergren, a staff scientist in Oak Ridge National Laboratory’s Plant Systems Biology group, is using his expertise in applied math and machine learning to develop neural networks to quickly analyze the vast amounts of data on plant traits amassed at ORNL’s Advanced Plant Phenotyping Laboratory.

Researchers tackling national security challenges at ORNL are upholding an 80-year legacy of leadership in all things nuclear. Today, they’re developing the next generation of technologies that will help reduce global nuclear risk and enable safe, secure, peaceful use of nuclear materials, worldwide.

Scientists at Oak Ridge National Laboratory and six other Department of Energy national laboratories have developed a United States-based perspective for achieving net-zero carbon emissions.

The U.S. Environmental Protection Agency has approved the registration and use of a renewable gasoline blendstock developed by Vertimass LLC and ORNL that can significantly reduce the emissions profile of vehicles when added to conventional fuels.

ORNL’s Erin Webb is co-leading a new Circular Bioeconomy Systems Convergent Research Initiative focused on advancing production and use of renewable carbon from Tennessee to meet societal needs.

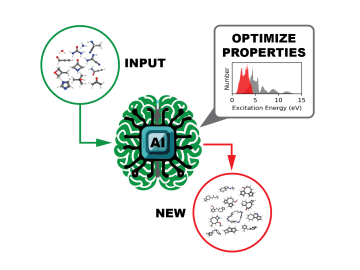

A team of computational scientists at ORNL has generated and released datasets of unprecedented scale that provide the ultraviolet visible spectral properties of over 10 million organic molecules.

Scientists working on a solution for plastic waste have developed a two-step chemical and biological process to break down and upcycle mixed plastics into valuable bioproducts.

ORNL scientists had a problem mapping the genomes of bacteria to better understand the origins of their physical traits and improve their function for bioenergy production.

Carrie Eckert applies her skills as a synthetic biologist at ORNL to turn microorganisms into tiny factories that produce a variety of valuable fuels, chemicals and materials for the growing bioeconomy.

Four first-of-a-kind 3D-printed fuel assembly brackets, produced at the Department of Energy’s Manufacturing Demonstration Facility at Oak Ridge National Laboratory, have been installed and are now under routine operating