Filter News

Area of Research

- Advanced Manufacturing (3)

- Biological Systems (1)

- Biology and Environment (35)

- Clean Energy (52)

- Computational Biology (1)

- Fusion and Fission (19)

- Fusion Energy (4)

- Isotopes (18)

- Materials (23)

- Materials for Computing (3)

- National Security (13)

- Neutron Science (10)

- Nuclear Science and Technology (16)

- Quantum information Science (1)

- Supercomputing (19)

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (43)

- (-) Bioenergy (51)

- (-) Biomedical (31)

- (-) Cybersecurity (14)

- (-) Isotopes (31)

- (-) Nuclear Energy (56)

- (-) Transportation (27)

- Advanced Reactors (8)

- Artificial Intelligence (51)

- Big Data (29)

- Biology (60)

- Biotechnology (12)

- Buildings (23)

- Chemical Sciences (27)

- Clean Water (15)

- Climate Change (52)

- Composites (8)

- Computer Science (89)

- Coronavirus (17)

- Critical Materials (5)

- Decarbonization (47)

- Education (2)

- Emergency (2)

- Energy Storage (30)

- Environment (105)

- Exascale Computing (29)

- Fossil Energy (4)

- Frontier (26)

- Fusion (31)

- Grid (26)

- High-Performance Computing (48)

- Hydropower (5)

- ITER (2)

- Machine Learning (23)

- Materials (44)

- Materials Science (47)

- Mathematics (7)

- Mercury (7)

- Microelectronics (3)

- Microscopy (20)

- Molten Salt (1)

- Nanotechnology (16)

- National Security (46)

- Net Zero (8)

- Neutron Science (51)

- Partnerships (21)

- Physics (31)

- Polymers (8)

- Quantum Computing (22)

- Quantum Science (32)

- Renewable Energy (1)

- Security (12)

- Simulation (33)

- Software (1)

- Space Exploration (12)

- Statistics (1)

- Summit (31)

- Sustainable Energy (48)

- Transformational Challenge Reactor (3)

Media Contacts

After retiring from Y-12, Scott Abston joined the Isotope Science and Engineering Directorate to support isotope production and work with his former manager. He now leads a team maintaining critical equipment for medical and space applications. Abston finds fulfillment in mentoring his team and is pleased with his decision to continue working.

A new convergent manufacturing platform, developed in only five months at the Department of Energy’s Oak Ridge National Laboratory, is debuting at the International Manufacturing Technology Show, or IMTS, in Chicago, Sept. 9–12, 2024.

Nuclear physicists at the Department of Energy’s Oak Ridge National Laboratory recently used Frontier, the world’s most powerful supercomputer, to calculate the magnetic properties of calcium-48’s atomic nucleus.

Jeremiah Sewell leads a team at ORNL, working on xenon-129 production for lung imaging. Reflecting on his career, Sewell views each opportunity as a "door" he steps through, leveraging over 25 years of experience in nuclear power and centrifuge operations to advance the facility’s mission.

Benjamin Manard, an analytical chemist in the Chemical Sciences Division of the Department of Energy’s Oak Ridge National Laboratory, will receive the 2024 Lester W. Strock Award from the Society of Applied Spectroscopy.

Two additive manufacturing researchers from ORNL received prestigious awards from national organizations. Amy Elliott and Nadim Hmeidat, who both work in the Manufacturing Science Division, were recognized recently for their early career accomplishments.

Brian Sanders is focused on impactful, multidisciplinary science at Oak Ridge National Laboratory, developing solutions for everything from improved imaging of plant-microbe interactions that influence ecosystem health to advancing new treatments for cancer and viral infections.

Brittany Rodriguez never imagined she would pursue a science career at a Department of Energy national laboratory. However, after some encouraging words from her mother, input from key mentors at the University of Texas Rio Grande Valley, or UTRGV, and a lot of hard work, Rodriguez landed at DOE’s Manufacturing Demonstration Facility, or MDF, at Oak Ridge National Laboratory.

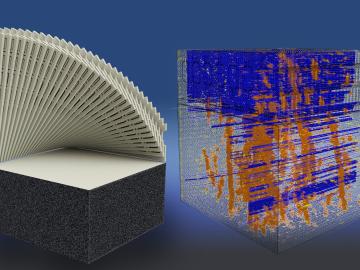

The Department of Energy’s Oak Ridge National Laboratory has publicly released a new set of additive manufacturing data that industry and researchers can use to evaluate and improve the quality of 3D-printed components. The breadth of the datasets can significantly boost efforts to verify the quality of additively manufactured parts using only information gathered during printing, without requiring expensive and time-consuming post-production analysis.

SCALE users from 85 organizations across 21 countries gathered online and in person at Oak Ridge National Laboratory from June 5 to June 7 for the Eighth Annual SCALE Users Group Workshop. The meeting included 32 presentations and 14 hands-on tutorials on impactful and innovative applications of SCALE.